German electronic 3D printing firm Neotech AMT has announced the launch of a new EU-backed Penta project AMPERE which is seeking to develop reliable and scalable hybrid additive manufacturing processes for producing multi-functional 4D mechatronic systems.

Mechatronics refers to a branch of engineering that brings together electronic, electrical and mechanical engineering systems, including a combination of robotics, electronics, computers, and telecommunications, among other things.

Meanwhile, 4D printing is a nascent process by which a 3D printed object transforms itself into another structure over time as a result of an external energy input like temperature or light.

To combine and develop these two emerging ideas, a consortium of 10 leading research and industrial partners from Germany and the Netherlands have come together for the AMPERE project, which will run until March 31st, 2024.

“The AMPERE project is a hugely exciting and ambitious project in the field of AM and will generate substantial business benefits,” said Dr. Martin Hedges, Managing Director of Neotech. “The project will enable unique product designs, that for the first time combine mechanical, electrical and optical functionalities produced at the industrial scale.

“Furthermore, the flexible nature of the developed production systems will allow faster response to changes in the market and open up new application areas for this emerging technology.”

Neotech’s previous project engagement

Neotech has previously engaged in several projects to advance 3D printing. One of these focused on the development of hybrid manufacturing techniques for 3D printed polymers and 3D printed electronics, while another explored the printing of ceramic substrates as a compliment to electronics 3D printing.

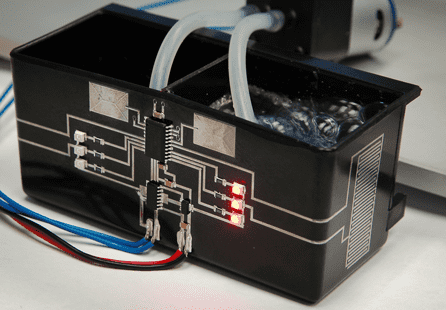

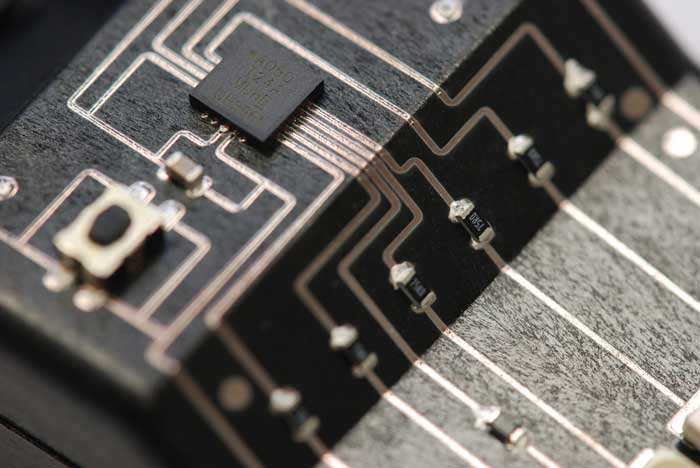

The company also presented its “Fully Additive” 3D printed electronic devices at RapidTec in 2019, which were equipped with electronics functionality both externally and embedded within the device’s 3D printed body.

Most recently, Neotech launched a joint project with the TAMS-group at the University of Hamburg to develop an artificial intelligence (AI) driven quality assurance system for 3D printed electronics. The project aims to pave the way for closed-loop control for hybrid additive manufacturing processes and the reduction of printing errors.

Developing scalable 4D printing

The consortium partners are working together under the Penta project’s AMPERE call to address the challenges created by the rapid development of the global digital economy through the creation of new technological innovations.

Penta is guided by the Electronic Components & Systems (ECS) Strategic Research and Innovation Agenda (SRIA), and is focused on accelerating scalable digital 4D manufacturing to bring the reliable production of smart systems for lighting, signal and power electronics, and medical devices closer.

Joining Neotech in the consortium is the Eindhoven University of Technology, the Fraunhofer-Gesellschaft zur Förderung der angewandten Forschung e.V., Philips Electronics Nederland BV, Reden BV, Signify, TNO, VSL BV, Wurth Elektronic GmbH, and XENON Automation GmbH.

Over the duration of the AMPERE project, the 10-strong consortium will embark upon developing and combining additive manufacturing technologies for the production of such smart 4D mechatronic products.

The goal is to develop these technologies to be both robust and scalable, capable of facilitating the manufacture of small series and mass customized products as well as high production volumes of more than 10,000 parts.

The products created during the project will feature a combination of integrated mechanical, electrical and optical functionalities, and will be equipped with what Neotech describes as “smart processes”.

The consortium partners will demonstrate their developed hybrid manufacturing approaches through three mechatronic product case studies. They will produce LED luminaires, signal and power electronics, and medical devices using their developed processes.

Advancements in 4D printing

When the shape of a 3D printed object changes over time, it is referred to as 4D printing. Still very much in its nascent stage, 4D printing has increasingly become the subject of multiple studies as researchers seek to improve and understand the process in order to unlock its potential applications.

In March last year, the Singapore University of Technology and Design (SUTD) and Nanyang Technological University (NTU) carried out a research project that culminated in a 3D printed material changing its shape back and forth without external force.

Meanwhile, researchers from Rice University in Texas developed a new method for enabling increased control over shape-shifting materials in 4D printing. The technique allows 3D printed objects to be manipulated to take on alternate forms when exposed to changes in temperature, electric currents, or stress.

Elsewhere, a team of researchers from Linköping University produced a set of microactuators for soft micro-robotics that are equipped with 4D capabilities. The 3D printed actuators contain an electrically active polymer that changes shape after printing, and the researchers believe their work shows great potential for the miniaturization of low-cost 3D printed micro robotics.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews and webinar replays.

Featured image shows a fully additively manufactured luminaire as part of the Penta project. Image via Neotech AMT.