Researchers from ETH Zurich, Switzerland have fused 3D printing with casting methods to devise an “eggshell” concrete 3D printing process.

Combining large-scale robotic Fused Deposition Modeling (FDM) 3D printing with the simultaneous casting of a fast-hardening, set-on-demand concrete, enabled the team to produce complex structures in a more material-efficient way. Moreover, casting the fast-hardening concrete within a continuous process minimized the lateral pressure on the material, allowing for the creation of printed concrete sculptures with complex geometries.

Using this technique, and working with German engineering firm Basler & Hofmann, the Zurich team ‘planted’ a “future tree” in the courtyard of the company’s headquarters. This concrete model, in addition to others produced by the team, could indicate the potential of the process for mass customization and structural optimization within concrete architecture.

“This novel fabrication process, known as “eggshell”, allows for the fabrication of non-standard, structurally optimized concrete structures, whilst being able to integrate standard reinforcement and minimize formwork waste,” stated the researchers.

“As a first built example using this fabrication method, it shows that non-standard concrete structures can be fabricated efficiently, economically and sustainably.”

Why the need for a novel concrete 3D printing process?

Concrete is the most-used building material in the world. In order for concrete to be 3D printed in a construction setting though, it needs to be supported by formwork as it transitions from a fluid material into a solid. This can be expensive, constituting up to 50 percent of the material’s cost, or even 80 to 90 percent for non-standard elements.

As a result, although concrete can theoretically be shaped into almost any form, standard, orthogonal structures remain the norm. This implies that such buildings are constructed using more material than is truly needed, thus creating the opportunity for the development of an alternative approach. While FDM 3D printing has shown promise within construction applications, the method’s speed, scale, and inability to produce thin, fragile printed structures to hold the fresh concrete in place, has prevented its widespread adoption.

Having been developed from “Contour Crafting” techniques, concrete 3D printing remains an area of constant study for many research institutions. Nonetheless, according to the Zurich team, these methods also have problems, as cold joints occur between the layers of printed concrete, and it remains difficult to integrate reinforcement within such printed structures. These issues have limited concrete 3D printing’s implementation to non-load-bearing structures or as lost formworks.

The Smart Dynamic Casting (SDC) method developed by an earlier team of Zurich researchers in 2014, offered a different approach. By using a digital casting process and controlling hydration of the concrete, the material at the exit of the moving formwork is able to carry the load of the material above. While this process was faster than previous methods, the range of geometries it was capable of producing remained limited, due to the complex mechanical actuation needed for the dynamic moving formwork.

The Zurich eggshell methodology

Attempting to utilize the benefits of the SDC process while eliminating its drawbacks, the modern Zurich team devised their eggshell concept. The novel technique merges large-scale robotic FDM 3D printing with the set-on-demand digital casting system developed within SDC. This allows for the creation of more complicated structures using a thin, single-layered shell as formwork.

“By printing the formwork instead of actuating it as in SDC, a much wider range of geometries can be produced without losing the advantage of being able to include traditional reinforcement in structural building components,” explained the researchers. In addition, simultaneously 3D printing and filling the formwork means that the structure doesn’t need to be moved during fabrication, thus reducing any risk of damage caused during transit.

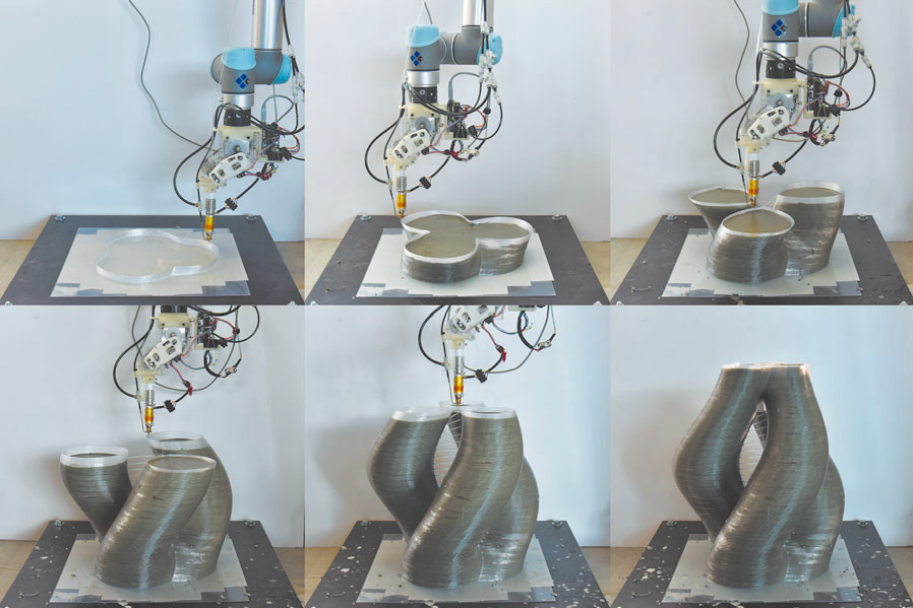

In order to test their newly-devised additive technique, the Zurich researchers produced a branching column, twisted column, and a “future tree” concept. To create these concrete structures, the team utilized a robotic arm that was controlled by a custom-developed Python interface, to construct the columns based on pre-programmed CAD files. Wielding a self-built filament extruder on the end of each arm, the bot was able to 3D print the formwork.

The casting element of the process saw the team mix concrete for a total of eight hours and summarily activate it using a custom-accelerator mix. Once the mixture had been 3D printed, the researchers experimented with a range of solutions to support their concrete columns. These included adding to the concrete’s matrix, placing hooked fibers in between casting layers, and applying post-installed fabricated ducts, but they concluded that optimum results could only be achieved by combining these approaches.

3D printed concrete columns and “the future tree”

While the resulting columns were found to be self-supporting within one or two hours, the Zurich team found that leaving the structures for a further three days resulted in better curing conditions. In their final form, the concrete structures displayed no cold joints between their layers, and the more complex twisted-column demonstrated the process’s ability to fabricate more complex geometries.

In addition to their concrete columns, the team also created a larger-scale tree-like structure nicknamed “the future tree.” Collaborating with German engineering firm Basler & Hofmann, the researchers constructed the tree using a combination of their eggshell process and a number of timber elements that acted as a reciprocal frame. Covering 1,152 square feet, or over 107 square meters, the canopy consists of 380 acetylated timber elements joined with screws, which are attached to a nearby building on two sides. These are supported by the tree’s concrete ‘stem,’ which is anchored to a nearby building on two sides and cantilevering on the opposite corner.

“Here, motivated by the frame’s structural behavior, the honeycomb pattern gradually transforms between a hexagonal and a triangular in order to achieve varying levels of flexural rigidity in different areas of the frame,” explained the tree’s designers. “The increasingly triangular configuration in the cantilevering corner makes this area stiffer and locally minimizes structural deformations.”

Overall, the Zurich team has conceded that a faster version of the method will need to be developed in order to prevent the joints of their creations from going dry. Additionally, the researchers are working towards automating the process and utilizing more recyclable materials within it, to make the method more sustainable and financially viable. Nonetheless, they remain confident that a more advanced version of their eggshell approach could be used within a wide range of building applications.

“As research progresses and the process is stabilized and streamlined, the range of building components produced could extend to beams, floor slabs, or connecting and transitional elements, paving the way toward sustainable mass customization in concrete architecture,” concluded the Zurich researchers.

Concrete construction and the 3D printing industry

Concrete 3D printing has begun to garner some serious attention from a range of companies and research facilities around the world. Scientists at Singapore’s Nanyang Technological University (NTU) for instance, have developed a single-robot 3D printing platform for creating concrete structures. By adopting a print-while-moving approach, the team’s robotic arm is capable of 3D printing large structures all by itself.

U.S-based concrete specialists QUIKRETE and Contour Crafting Corporation (CC Corp), meanwhile, have partnered up to 3D print a range of concrete buildings around the United States. The goal of the project is to build low-income housing and disaster relief facilities.

Engineers from Purdue University, on the other hand, have begun working on a method of 3D printing concrete wind turbine parts for offshore use. The Purdue research aims to 3D print steel wind turbine anchors out of concrete, to reduce the associated shipping and production costs.

The researchers’ findings are detailed in their paper titled “Eggshell: Ultra-Thin Three-Dimensional Printed Formwork for Concrete Structures.” The report was co-authored by Joris Burger, Ena Lloret-Fritschi, Fabio Scotto, Thibault Demoulin, Lukas Gebhard, Jaime Mata Falcon, Fabio Gramazio, Matthias Kohler and Robert J. Flatt.

You can now nominate for the 2020 3D Printing Industry Awards. Cast your vote to help decide this year’s winners.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the ‘future tree’ built by the ETH Zurich team and engineers from German company Basler & Hofmann. Photo via ETH Zurich.