ETH Zurich researchers have 3D printed bioresorbable stents that are designed to provide less invasive oxygen relief to those suffering from airway obstruction.

By combining two monomers, the team has been able to create a novel cell-compatible resin, that once cured by a DLP 3D printer, can be used to fabricate patient-specific tracheal implants. Having tested their devices on rabbits, the scientists believe they could now find end-use clinical applications, preventing patients from choking without the need for intrusive surgical removal.

“This promising development opens up prospects for the rapid production of customized medical implants,” said Jean-Christophe Leroux, Professor of Drug Formulation and Delivery at ETH Zurich, “as well as devices that need to be very precise, elastic and degradable in the body.”

Improving anti-choking devices

In acute cases, diseases such as asthma, cystic fibrosis and bronchitis can cause what’s clinically described as a Central Airway Obstruction (CAO) in the tracheas of affected patients. When this happens it’s effectively a medical emergency, as if the patient doesn’t find help and gets too little oxygen, they risk death by suffocation.

Thankfully, sufferers can often be treated using silicone airway stents, but many commercial devices are rudimentary, not patient-specific and subject to migration, which can cause complications. Similarly, when stents are used within pediatric patients, their throats tend to change shape as they grow, necessitating invasive replacement surgeries.

As a result, the Zurich team have identified the need for a biodegradable device that can be customized to the needs of individual patients. While FDM 3D printing has previously yielded dissolvable implants, they’re often too malleable, and subject to deformation before they can be inserted into the CAO sufferer’s throat.

Similarly, researchers have attempted to use DLP systems to fabricate stents before, but found that resin viscosity prevented the approach from being viable. The Zurich team even 3D printed dissolvable aluminum implants themselves in 2019, and building on this approach, they opted to develop an application-specific bio-resin.

3D printing the bioresorbable stents

To create their material, the scientists mixed DLLA and CL monomers at a very precise ratio that they calculated would provide the formula with bio-friendly properties. The team then deployed a customized DLP 3D printer that only printed at 70 to 90°C, to cure the resin into a polymer, without making it too viscous.

During testing, the researchers found that they were able to adjust the properties of printed objects by tweaking the chain length of their monomers, which in-turn affected cross-linking density. The most suitable material formula featured long and flexible polymer chains, which gave it a tensile stress of 10 MPa, significantly less than that of silicone stents.

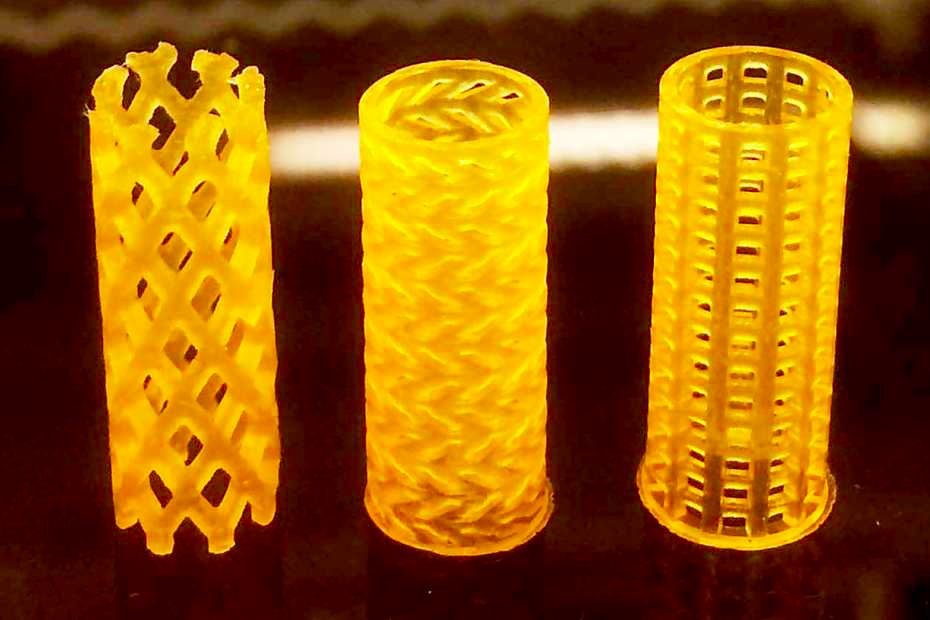

Wielding their optimized polymer mix, the Zurich team then 3D printed three different prototypes, and put them through ISO-standard evaluations. Results showed that subjecting the devices to moisture and heat caused them to undergo significant weight loss, and those warmed up to 50°C lost 70% of their total mass.

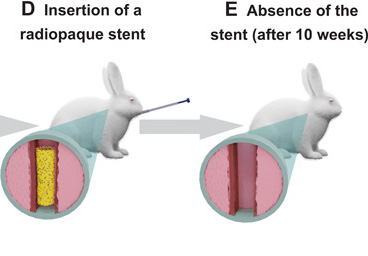

As a final test, the scientists took CT images of six rabbits’ tracheas and fabricated stents to fit the exact throat geometry of each test subject. After the devices had been transplanted, the researchers observed that despite causing inflammation, the additive stents had completely dissolved over a period of ten weeks.

According to André Studart, head of the Complex Materials Group at ETH Zurich, the novel devices could soon find their way into end-use scenarios. “Producing such stents on a large scale is a complex undertaking that we still need to study better,” concluded Studart. “It is hopefully only a matter of time before our solution finds its way into the clinic.”

Advances in 3D printed stents

Although the ETH team’s polymer may be novel, they’re not the first to successfully develop biocompatible stents, and a team from the Ohio-based non-profit Cleveland Clinic have even managed to gain FDA approval for their 3D printed patient-specific devices.

Researchers at Eindhoven University of Technology, meanwhile, have developed similar 3D printed dissolvable stents, but for pediatric heart surgery applications. The self-expanding devices are specifically designed to open up the arteries of children affected by heart disease.

Similarly, a team based at Pohang University of Science and Technology (POSTECH) have 3D printed cell-derived stents that help to ease the symptoms of esophagitis. The scientists believe that their device could be loaded with other cells in future, as a means of treating local injuries such as burns or wounds.

The researchers’ findings are detailed in their paper titled “Digital light 3D printing of customized bioresorbable airway stents with elastomeric properties.”

The research was co-authored by Nevena Paunović, Yinyin Bao, Fergal Brian Coulter, Kunal Masania, Anna Karoline Geks, Karina Klein, Ahmad Rafsanjani, Jasmin Cadalbert, Peter W. Kronen, Nicole Kleger, Agnieszka Karol, Zhi Luo, Fabienne Rüber, Davide Brambilla, Brigitte von Rechenberg, Daniel Franzen, André R. Studart and Jean-Christophe Leroux.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows two of the ETH Zurich team’s 3D printed airway stents. Photo via the Science Advances journal.