Industrial 3D printer manufacturer Essentium has launched its new High Speed Extrusion (HSE) 240 HT Dual Extruder 3D printing system.

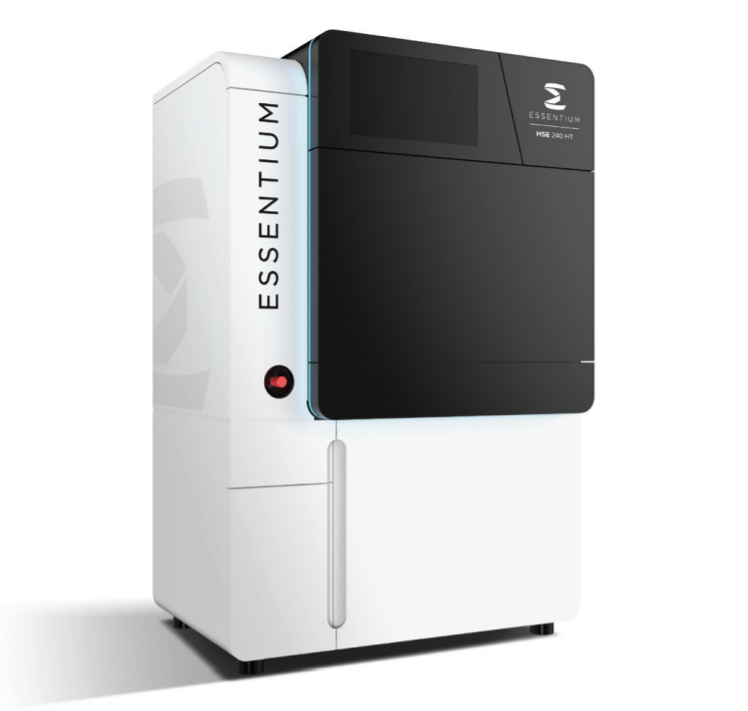

Debuted at last week’s Formnext trade show, the HSE 240 HT Dual Extruder is designed to be a “compact powerhouse” with a footprint small enough to be installed in small and medium-sized factory space and university labs, while maximizing the performance, reliability and efficiency of parts production.

“Whether a manufacturer is creating a one-off jig or scaling up their entire production, they need AM solutions that remove the complexity of traditional manufacturing and deliver savings in order of magnitude while speeding time to market,” said Blake Teipel, CEO of Essentium.

“The small yet mighty Essentium HSE 240 HT Dual Extruder 3D Printer has been designed to empower manufacturers challenged with space constraints to enjoy transformative AM opportunities at the speed, scale, and economics they have come to rely on from Essentium.”

Essentium’s HSE technology

First launched in 2018, Essentium’s HSE platform aims to address the speed and strength drawbacks of traditional FDM/FFF 3D printers. The company began scaling the production of the platform the following year, and expanded on existing relationships with key industry players such as BASF and Materialise to introduce an open model for high-speed 3D printing.

Since then, Essentium has introduced several high-temperature filaments for the HSE platform, including composite filaments suited to aerospace, defense and electronics applications, and its high-performance PEKK filament.

The company’s newest machine follows the introduction of the HSE 280i HT IDEX FFF printing system in April this year. Designed for the shop floor, the HSE 280i HT enables aerospace, automotive and electronics manufacturers to produce high-volume functional prototypes and production parts using the company’s high-performance engineering filaments.

In addition to debuting its newest machine, Essentium made several other announcements at Formnext 2021. The firm introduced its Essentium PPS-CF carbon-fiber-reinforced filament made with LUVOCOM 3F resin from LEHVOSS Group, and launched a 5kg spool that allows users to continuously print large parts and tools through minimizing the number of spool swaps required during printing.

The company also revealed the findings of its independent global research on the current and future use of 3D printing, which state that the use of large-scale 3D printing has more than doubled in the past year for the majority of manufacturing companies.

The HSE 240 HT Dual Extruder 3D Printer

Essentium’s newest machine bolsters the firm’s extrusion-based 3D printing portfolio, which also includes the HSE 280i HT platform and the HSE 180 Series.

Measuring 1,168 x 795 x 1,687 mm (w x d x h), the HSE 240 HT Dual Extruder system is engineered for the reliable and efficient production of parts within a small footprint. Designed to fit in small and medium-sized factory spaces and university labs, the machine is capable of accelerating the time-to-production of complex parts, while significantly reducing post-processing costs.

In addition to its single dual extrusion print head, the HSE 240 HT features automatic filament switching to reduce downtime and enable the fabrication of more parts within a compact environment. Equipped with three print modes, the machine can produce highly accurate parts from different materials in a single print, without compromising on part quality or performance.

The HSE 240 HT operates on Essentium’s open materials platform, giving users access to high-performance filaments such as TPU, PEKK, PEEK and High-Temperature Nylon. The open material platform gives users greater flexibility in their material printing options, providing them with the design freedom to bring their creations to life.

Essentium believes its latest machine is well-suited to meet the requirements of demanding applications in sectors such as aerospace, defense and automotive.

Technical specifications and pricing

While those interested in pricing can request a quote for the HSE 240 HT from Essentium’s website, the technical specifications for the machine are as follows:

| Technology | High Speed Extrusion |

| Print heads | One dual extrusion print head |

| Motion System Accuracy (single head mode) | 0.081 mm at 70 mm/s 0.091 mm at 300 mm/s |

| Position accuracy | XY < 30μm, Z < 5μm |

| Part accuracy | 15% or 0.25 mm (whichever is larger) |

| Encoder accuracy | 1μm |

| Part speed | 375 mm/s |

| Build volume | 430 x 350 x 375 mm |

| Nozzle | Hozzle heated nozzle |

| Nozzle diameters | 0.4, 0.8 mm |

| Bed plate temperature | Up to 190°C |

| Build chamber temperature | Up to 185°C |

| Printer dimensions | 1,168 x 795 x 1687 mm |

| Net weight | 452 kg |

| Additional features | Non-slip, high-torque extrusion system X-Y stage linear servo motors |

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews and webinar replays.

Featured image shows Essentium’s HSE 240 HT Dual Extruder 3D Printer. Photo via Essentium.