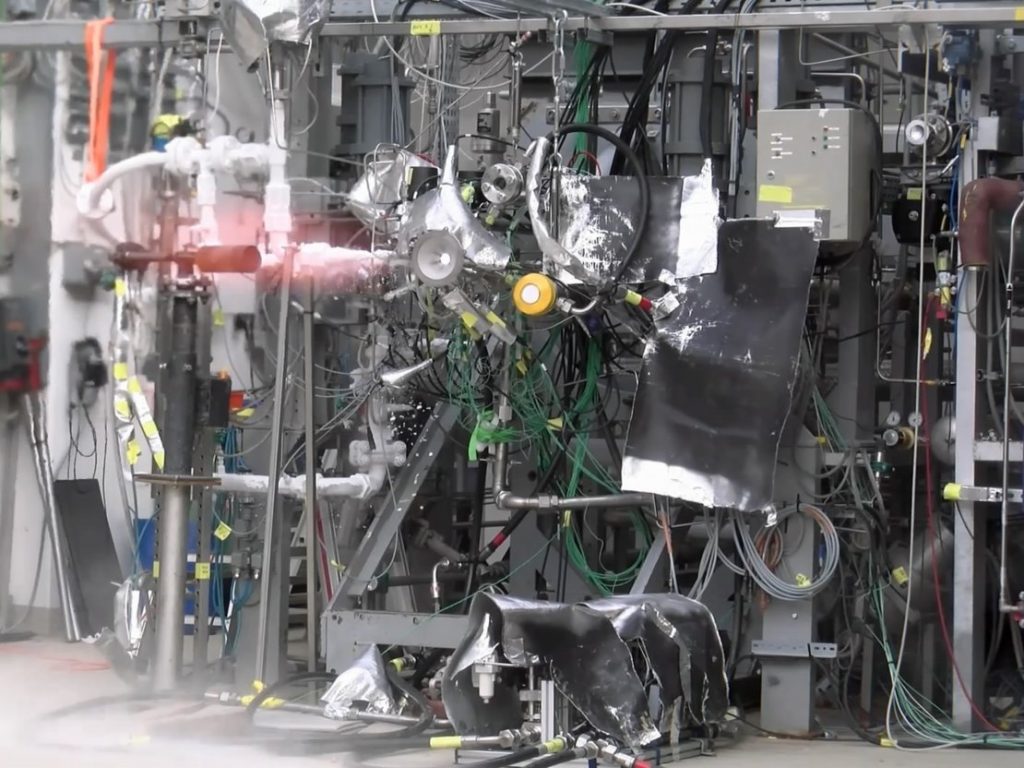

The European Space Agency (ESA) has completed the first hot fire testing of a full scale, 3D printed rocket engine demonstrator named BERTA (Biergoler Raumttransportaengine/Biergoler space transport drive). Fired at the German Aerospace Center (DLR) in Lampoldshausen, the additive manufacturing process used to produce this engine is part of the development pipeline of the Ariane 6 launch vehicle – a project valued at €3.6 billion ($4 billion USD).

Lysan Pfützenreuter, project manager at DLR Space Management, comments, “Additive manufacturing opens up new ways for Europe to manufacture engines,”

“The successful demonstration of the technology is an important step towards improving the competitiveness of European launcher systems.”

3D printed rocket engines

As a relatively cost effective production method for such complex parts, additive manufacturing is finding widespread use across R&D efforts in the aerospace industry. This is particularly evident in the development of engines that use storable liquid propellants, e.g. liquid oxygen (LOX) methane, which are reusable, and much simpler than those that require an ignition system. Launcher’s E-2 is one example of a 3D printed LOX engine, which made headlines last week for its record-breaking single-piece attempt. The Orbex Prime engine is another, which was produced in collaboration with SLM Solutions.

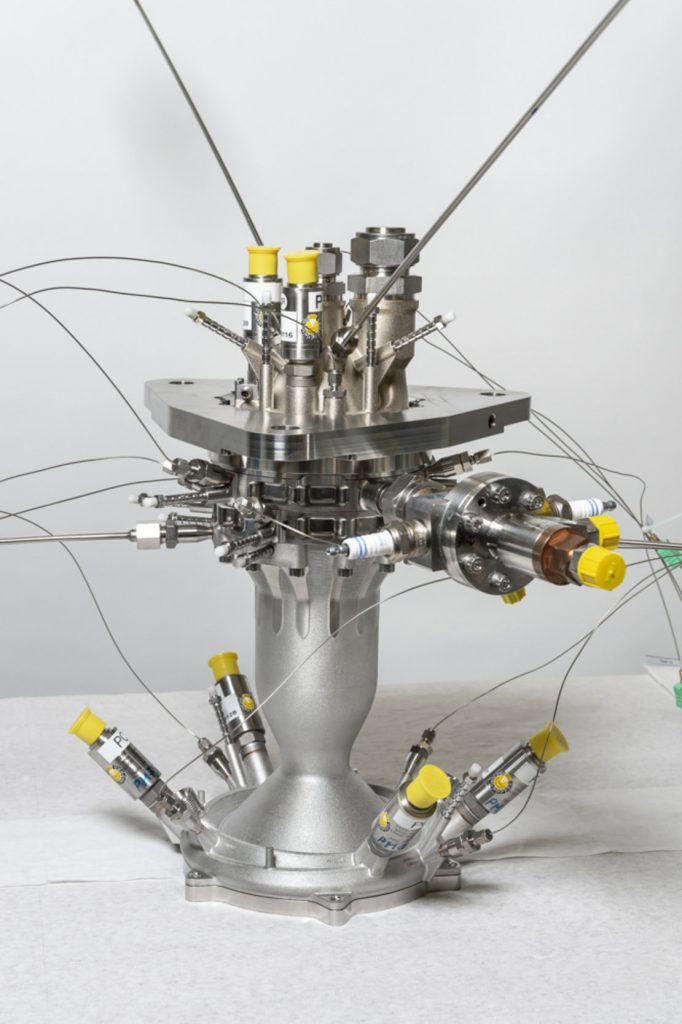

The BERTA engine, developed by ArianeGroup at ESA, was produced using selective laser melting (SLM), from a nickel-based alloy (for the injection head) and stainless steel (the combustion chamber). A demonstration at present, this engine is a step toward the agency’s ultimate goal of producing 3D printed engines that can propel rockets to the moon (384,000 km above Earth) and beyond.

A European first

One of the advantages of 3D printing BERTA, was the engineers’ ability to add more complex cooling channels to the engine’s interior. Eventually, this integration will lead to more compact engines, a positive for material economy. In the first test of a month-long series on the BERTA, DLR engineers successfully fired the engine for 560 seconds, at a reference thrust of 2.45 kN (550.78 lbf). Gerd Brümmer, DLR engineer and head of BERTA Test Stand P8, comments, “The aim of the current tests is to investigate the flow behaviour and heat transfer of printed surfaces.”

In addition, Brümmer says:

“This new technology can currently only be tested at Test Stand P8 in Lampoldshausen, Europe-wide.”

Remaining competitive in aerospace

BERTA’s continued testing is part of the ESA Future Launchers Preparatory Programme (FLPP) first launched in 2003 “to respond to Europe’s future institutional needs and to continue at the forefront of new developments in space.” Now in Period 3, the FLPP is seeking “New Economic Opportunities” to cut the time-to-market and price of the continent’s aerospace systems. The agency is also developing other additive manufacturing processes for application in larger engine demonstrators.

In relation to the BERTA’s first firing Wenzel Schoroth, propulsion engineer at ESA, comments, “3D printing and qualifying parts for hot-firing and ultimately flight is a challenge, especially when dealing with fine, complicated structures, like the cooling channels of our demonstrator.”

“This hot-fire test is a way of demonstrating the effectiveness of our processes, as well as learning more about the flow phenomena within additively manufactured rocket engines.”

Nominate ESA for Aerospace Application of the Year in the 2019 3D Printing Industry Awards. For regular additive manufacturing aerospace news updates subscribe to our newsletter, follow us on Twitter and like us on Facebook. Visit 3D Printing Jobs for new additive manufacturing opportunities in your area.

Featured image shows the BERTA thrust chamber demonstrator. Photo via DLR