China-based 3D printer manufacturer Eplus3D has made its debut in the railway sector with its latest customer project.

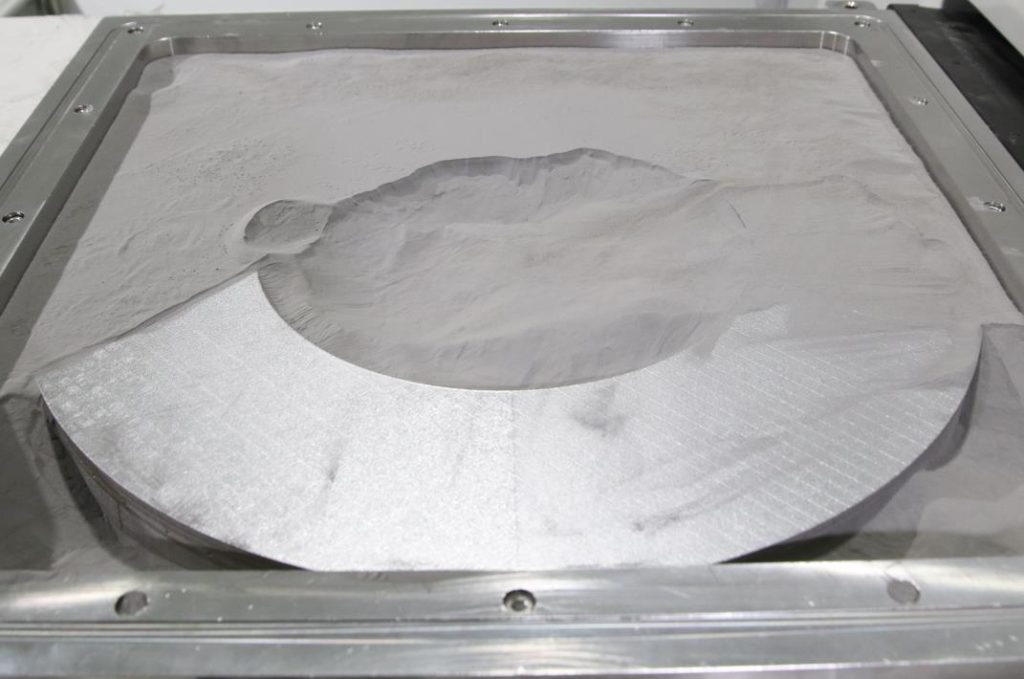

Working closely with an unnamed railway company, the firm used its large-format EP-M650 system to 3D print a set of custom end-use brake discs for use on a train. Measuring Φ 648 x 90mm³ each, the parts were printed using 24CrNiMo alloy steel with a total build time of 631 hours from start to finish.

The use case is the latest in a long line of 3D printing applications for Eplus3D, and reportedly yielded both lower costs and shorter lead times for the railway firm when compared with traditional production methods.

The need for high-performance brake discs

Much like aerospace and automotive, the railway industry is built on high-performance metal parts. Today’s high-speed trains can travel at top speeds of around 350km/h or more, with each carriage weighing approximately 60 tons. As such, moving trains have an enormous amount of inertia and kinetic energy behind them, which makes it extremely difficult to brake and stop in a short period of time.

Brake discs work simply by pressing against each other, which generates friction to counteract the rotation of a train’s wheels. Unfortunately, you can’t have friction without generating heat, so brake discs (and brake pads) are regularly required to withstand high temperatures of around 900°C. They’re also designed to work in a wide variety of harsh environments with rain, snow, sand, and sun.

Many of today’s brake discs are made of steel alloys and manufactured via conventional processes such as metal casting and forging. While these approaches do deliver excellent mechanical properties and surface finishes, they also suffer from excessively long production cycles. This is particularly troublesome when sourcing spare parts for replacements, as deliveries can take several months to complete with added costs at every step of the supply chain.

A new tool for the railway sector

Taking the additive manufacturing approach, Eplus3D made use of its EP-M650 3D printer, a quad-laser powder bed fusion system with a large-format build volume of 655 x 655 x 800mm.

The machine is compatible with a plethora of metal powders such as titanium, aluminum, Inconel, cobalt chrome alloys, and more. The 24CrNiMo steel used for the project is known for its high tensile strength, fracture toughness, and excellent thermal stability – crucial properties for brake discs.

As well as lending itself to much shorter delivery times and lower production costs, the use of 3D printing had several benefits in terms of part performance. According to Eplus3D, the 3D printed brake discs offered improved densities thanks to the reactivity of the high-power laser beam, resulting in better mechanical and friction properties. Since the surface features and holes were printed as one monolithic part, the brake discs were also found to offer superior heat dissipation.

Ultimately, Eplus3D sees a bright future for its 3D printers in the rolling stock sphere, providing a new and improved method of fabricating critical spare parts without sacrificing part performance.

Even still, Eplus3D isn’t the first company to leverage additive manufacturing technology in the transport sector. Just recently, Alstom, a France-based rolling stock manufacturer, adopted FDM 3D printing technology from Stratasys to streamline its own spare part production operations. One of the company’s latest projects involved producing a set of emergency spare parts for Algeria’s Sétif Tramways, drastically slashing lead times and saving Sétif Tramways thousands in manufacturing costs.

Elsewhere, Kimya, the additive manufacturing materials arm of technology company ARMOR, used 3D printing to produce an obsolete protective cover component for an unnamed railway supplier. Developed back in 1982, the mold for the cover no longer existed so the spare parts had to be redesigned from scratch before being 3D printed in PEEK.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

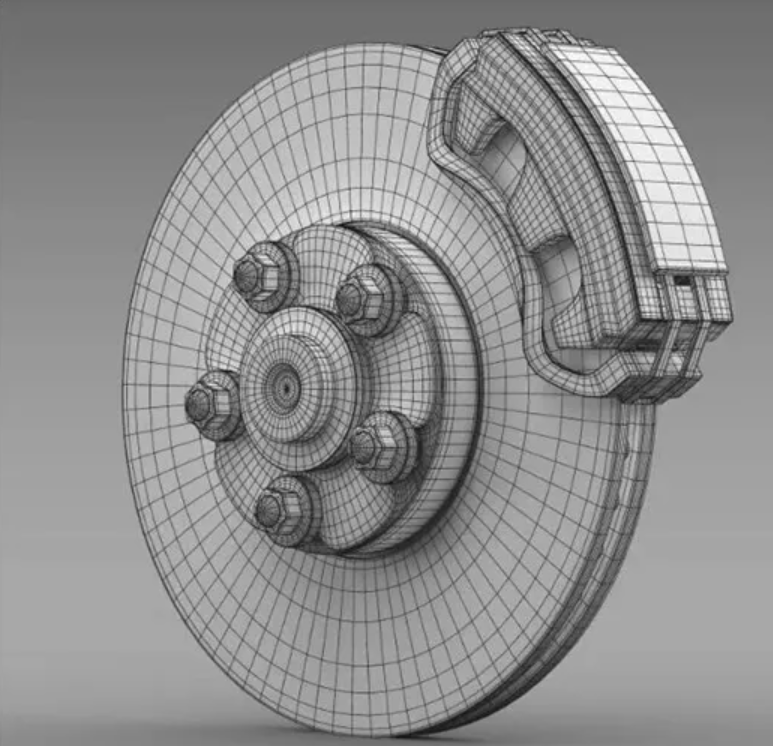

Featured image shows the digital brake disc design. Image via Eplus3D.