Leading industrial 3D printing supplier EOS, and German software start-up Additive Works have confirmed that they are working together to enhance metal additive manufacturing processes.

As part of the partnership, EOS is offering Additive Works’ Amphyon simulation based software to its customers, and the two companies have committed to the further development of the platform.

Martin Steuer, Head of Product Management Software and Services at EOS, explains, “United by the mission to make Industrial 3D printing even more intuitive and user friendly, EOS is happy to partner with Additive Works on the subject of AM-process-simulation,”

“‘Simulate before you create’ really is a key factor to ensure a successful laser sintering process with metal materials, right from the start.”

Simulate before you create

“Although the AM-technology itself is very mature,” states Dr. Nils Keller, CEO of Additive Works, “especially for unexperienced users it can be difficult to predict if a part will be 3D printed as expected.” This is particularly evident in the number of research projects and software/imaging developments of recent years which are seeking to study the exact behavior of the laser melting process.

Simulation then, which is a standard for traditional and subtractive manufacturing processes, is one way of avoiding issues like surface defects or interior residues.

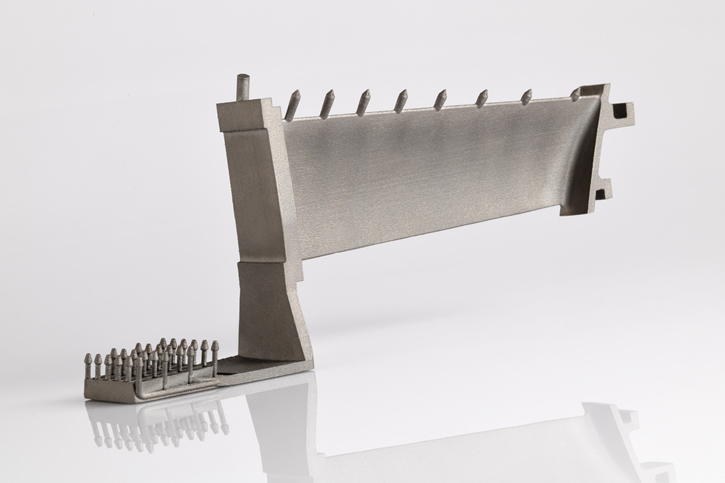

Amphyon is Additive Works’ solution for overcoming these challenges.

ASAP metal 3D printing

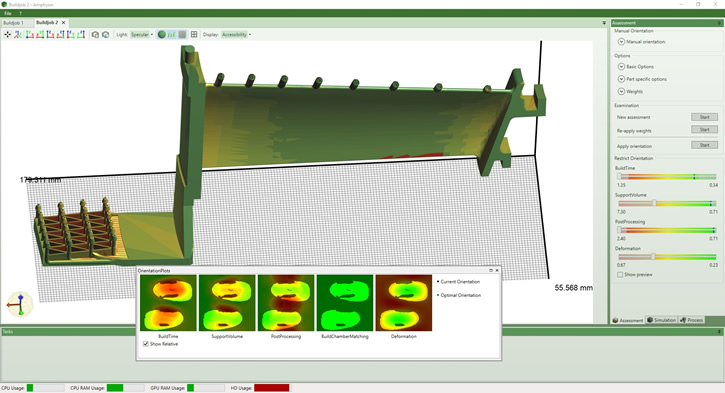

Amphyon can be summarized in four workflow principles: Assessment, Simulation, Adaption and Process, or ASAP.

Assessment – at this stage, the software estimates an object’s print time, material usage, the post processing needed and distortion sensitivities created by orientations within the build chamber.

Simulation – Next, Amphyon performs a calcification of the residual stress and distortions of the part.

Adaption – scan speed or laser power is adapted for the specific application.

Process – a “first time right” 3D print is completed.

Streamlining metal additive manufacturing

Additive Works was founded in 2015. Since then its proprietary Amphyon sofware, consisting of multiple programs, has been integrated by the likes of Altair, 3D Systems (in 3DExpert) and SLM Solutions.

Throughout its partnership with EOS, Additive Works will be help integrate Amphyon assessment, simulation and support modules into the company’s proprietary EOSPrint 2 3D printing software.

For software business updates and releases, follow 3D Printing Industry on Twitter, like us on Facebook, and subscribe to our newsletter.

Advertise 3D Printing Jobs now through our specialized site, or apply for new opportunities here.

Featured image shows Additive Works Amphyon Calculated-Distortion-Field. Image via Additive Works)