Being the number one producer of (and number one patent holder) of DLP technology based 3D printers, EnvisionTEC today finds itself in a situation which in some ways is similar to that experienced by Stratasys with FDM technology. Dozens of new, low cost DLP 3D printers are about to hit the market and, while the quality – and, even more importantly, the materials – that EnvisionTEC is able to offer are no walk in the park to replicate, the company knows it needs to diversify and continue to innovate to always remain a few steps ahead of the mounting competition.

As my friends at Nemesi – one of Italy’s main jewelry manufacturers – explained to me a few weeks back, the issue for jewelers is that 3D printing the castable model in wax gives them better finish while using castable resin materials gives them higher intricacy and resolution. EnvisionTEC’s solution allows jewelers to 3D print the castable models using high density, paste materials, something which was not previously possible with DLP technology.

EnvisionTEC thus also developed the E-Wax material, which is an industry-first paste substance mixed with a polymer binder for use with its 3D printers. “This new generation wax paste is built to cast everything from wedding bands to biker rings, from graduation rings to thick bracelets,”the company explained in a press release. Larger jewelry pieces will now be able to be investment casted regardless of wall thickness with no worries about porosity due to ash content, or metal flashing due to polymer expansion.

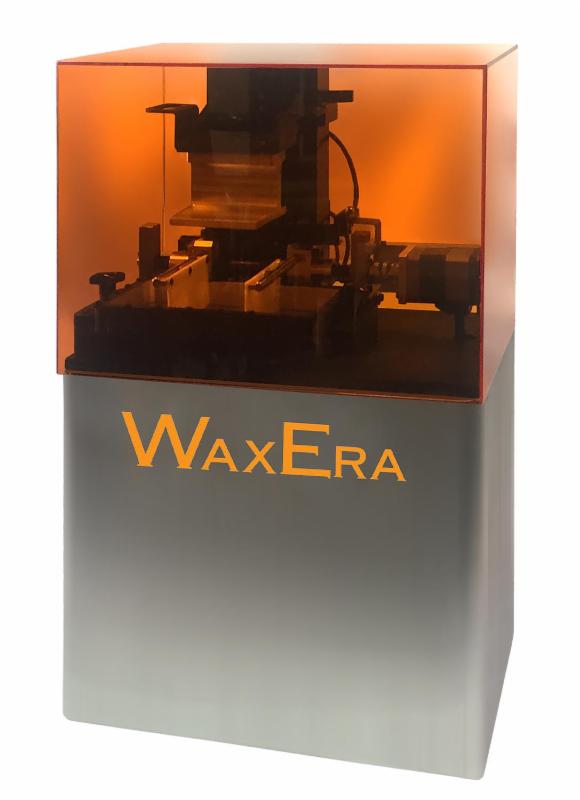

“Casters can also benefit from the ease of casting E-Wax in the same tree as traditional wax patterns in silver, yellow and white gold, as well as platinum – the company’s statement goes on – without the need for any significant change to standard burnout cycles or the use of sophisticated casting equipment.” It may seem like a relatively small innovation but in the multi-billion global jewelry industry even a small piece of innovation can bring about a new era, in this case a new WaxEra.