Ohio 3D printing company Additive Engineering Solutions (AES) are purchasing a Big Area Additive Manufacturing (BAAM) machine from Cincinnati Inc. The machine is famous for 3D printing a car live at IMTS in Chicago two years ago, in collaboration with Local Motors, and now AES will become the first 3D printing service company to offer printing through this machine. The company, initially a engineering consultancy firm, saw acquiring this printer, and in turn offering bureau based service, as too big an opportunity to miss.

Company background

Austin Schmidt, Partner and President of AES, and Andrew Bader, Partner and business development, started the company in August 2016. The pair met in 2015 when Schmidt was still working in additive manufacturing at Caterpillar. When they first began AES, they specifically intended not to buy 3D printers as they believed the market was over populated and difficult to stand-out in. However, they explain how the opportunity to have a BAAM machine provided them with an almost unique standpoint in the industry.

Since the company is now service orientated, owning a device like this means that other companies can use the machine rather than have to purchase one for themselves. Their 3D printer is one of the biggest in the 3D printing market, capable of printing parts 5 1/2 ft wide x 13 ft long x 6ft tall, and will therefore create considerable a demand, especially considering this is the first printer to be combined with AES’ consultancy expertise.

About the BAAM machine

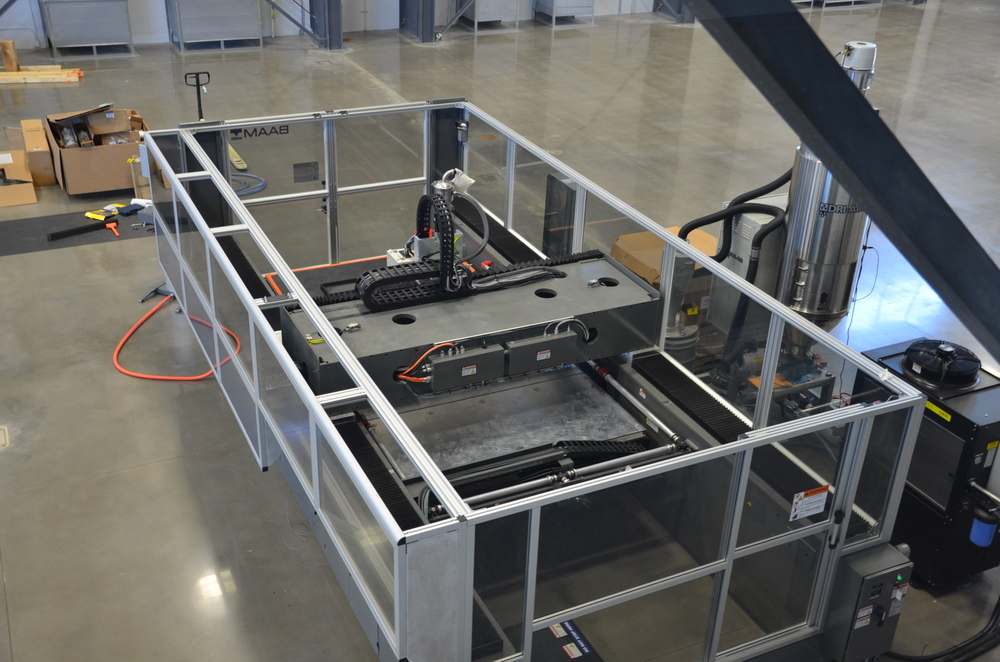

The machine created by Cincinnati Inc. is capable of 3D printing print large parts, such as the previous ‘world’s largest’ Boeing airplane trim created by Oak Ridge National Laboratory. It prints using the FFF method, and the company have suggested they are looking into the tooling market, which they believe is on-demand in Northern Ohio at the moment.

The large-scale additive manufacturing machine is expected to arrive just before the new year so AES can get started with it from 2017 onwards, having already travelled to Cincinnati Inc. several times to familiarize themselves with its use.

The 3D printer is the eleventh of it’s kind to be sold by Cincinnati Inc., but the very first sold to a 3D printing bureau. The other ten are used by universities or companies meaning this machine is the first to be made available to the wider audience. The printer can print parts that are up to 5 1/2 ft wide x 13 ft long x 6ft tall. AES divulged their total startup costs, including this machine, as about $1.5 million so expect a busy year from them in 2017.

Featured image of the Cincinnati Inc. BAAM machine and a Shelby Cobra with 3D printed chassis and body, by Oak Ridge National Laboratory. Image via Cincinnati Inc.