3D Printing Industry recently visited Munich for the MUST 3D Printing event. Taking place twice annually, the event is organised by the Munich Summit (MUST) – a project started in 2014 by LMU Entrepreneurship Center, the Strascheg Center for Entrepreneurship SCE and the UnternehmerTUM.

MUST 3D Printing brings together international Additive Manufacturing startups and provides targeted networking opportunities at an event intended to advance new business models for industrial 3D printing.

DyeMansion is one company that has benefited from attending previous editions, where co-founders Felix Ewald and Philipp Kramer met Arno Held, Chief Venture Officer at AM Ventures. Ewald told 3D Printing Industry that after a lengthy wait he was able to discuss the nascent company and received advice about the future direction of the business. “In just 15 minutes he was able to explain to us that we really should pivot our business and focus on industrial grade post-processing. Together with Arno we developed our business plan and nine months later AM ventures backed us. That was the beginning of DyeMansion.”

The most recent event took place at the University of Applied Sciences Munich and featured approximately 150 attendees – some who may be the additive manufacturing stars of the future.

3D printing startups

Dominic Solenicki, CEO and Co Founder of Sintratec, opened the event with a keynote presentation regarding Sintratec’s vision for the future of additive manufacturing. This was followed by pitches from 8 startups.

AMendate make automated topology optimisation software designed to optimise parts for additive manufacturing. Thomas Reiher, CEO and Co-Founder of AMendate highlighted the lack of an accessible and rapid solution for generating and preparing designs for Additive Manufacturing which led him to create his own software. AMendate is one of the winners of the formnext 2018 startup challenge.

Another formnext 2018 startup challenge winner is SLS printer manufacturer, Aerosint. Edouard Moens, CEO and Co-Founder of Aerosint described how his company’s selective powder deposition system allows for Multi Material SLS printing. Aerosint recently closed an €850k financing round.

A Swiss startup presenting at the event was Spectroplast, CEO Manuel Schaffner presented patented technology for 3D printing with silicone. Applications include food and beverages, aerospace and transportation. Spectroplast plan to enter the healthcare industry for exo-plants such as hearing aids and orthopedic insoles.

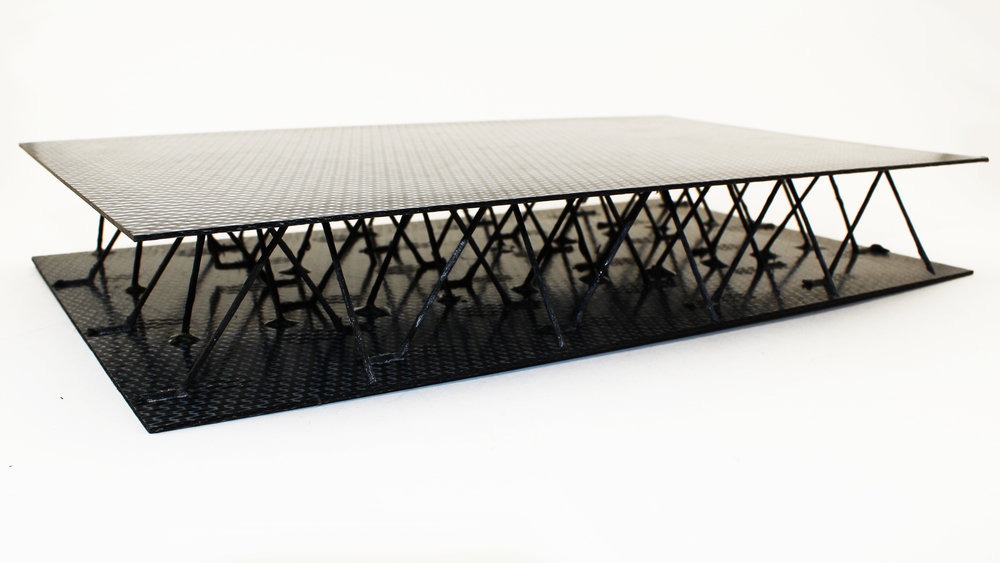

9t Labs are the developers of an FDM 3D printer that processes continuous carbon fibre reinforcement. The company plans to bring this technology to market within the coming months as a modular add-on for FDM machines.

Glassomer took to the stage with an innovative product, allowing fused silica glass to be 3D printed. Not commonly known as a 3D printable material, fused silica glass is more commonly modeled using wet chemical etching. Glassomer uses a silica nanocomposite available as a liquid or solid. As a liquid Glassomer can be structured by stereolithography 3D printing to create complex models. The Company demonstrated that once sintered, printed parts are chemically and physically indistinguishable from commercial fused silica glass, maintaining the same optical transparency, thermal and chemical stability and mechanical strength.

Cellbricks focuses on 3D bioprinting via a proprietary stereolithography based platform. CEO Lutz Kloke explained the company’s aim to set the benchmark for bioprinting offering high quality, speed and accessibility to 3D printing cell culture systems.

Bernstein Innovation presented an automated blasting solution for polymers and metals. Providing an end to end solution, Bernstein Innovation’s portfolio of capabilities ranges from bespoke material production, post processing and finishing to provide their customers with functional end use parts.

Youmawo founder Sebastian Zenetti presented his unique approach on how he aims to bring additive manufacturing into the luxury eyewear market. Youmawo uses 3D scanning in order to provide customers with bespoke fitted glasses optimised for their individual head shapes. 3D printed on EOS SLS machines, Youmawo eyewear is 30% lighter and more durable than traditional acetate frames.

For all of the latest updates direct from formnext 2018 and other leading industry events subscribe to the 3D Printing Industry newsletter, and join us on Facebook and Twitter.

Find your next career move or find new skilled additive specialists with 3D printing jobs.

Featured image shows AM Ventures and Dyemansion at Must 3D Printing 2018 in Munich. Photo by Oscar Milani Gallieni