E3D-Online Ltd, an award-winning UK-based 3D printing hotend and peripheral manufacturer, has released a new range of products for high-temperature 3D printing.

The latest release is part of E3D’s efforts to bring high-temperature engineering-grade PAEK filament to desktop 3D printers. These efforts have been successful with the help of Victrex, a manufacturer of high-grade polymers for 3D printing based in Lancashire.

PAEK filament has certain temperature requirements which must be maintained during the print. These demands are fulfilled by E3D’s high-temperature 3D printer components, enabling desktop FDM/FFF machines to print with PAEK filament.

High-temperature desktop 3D printer hotend

Desktop FDM/FFF printers are mostly used with PLA (optimal conditions 185°C-205°C) and ABS (230°C). These printers are not designed to operate above 260°C. Therefore, 3D printing PAEK which has an extrusion temperature between 380°C and 430°C is beyond the technical capabilities of such machines.

Another important consideration for printing with PAEK is the temperature of the heated bed. PAEK requires a 140˚C-160˚C heated bed in contrast to PLA and ABS, which ranges between 40°C-110°C.

Keeping this in mind, E3D’s has developed the high-temperature heater cartridge and the heater bed, which have made PAEK filament printing possible with desktop 3D printers.

A hotend heater cartridge is fitted inside the nozzle of the heater block. Its function is to heat the nozzle while loading up or starting a print.

E3D has designed the heater cartridge with high-gauge silicone fiber wires and ceramic insulation to make sure it withstands extremes of high temperature. A conductive thermal coating also guarantees that the heat is supplied evenly to the hotend.

These qualities make the heater cartridge capable of working with temperatures of up to 550°C.

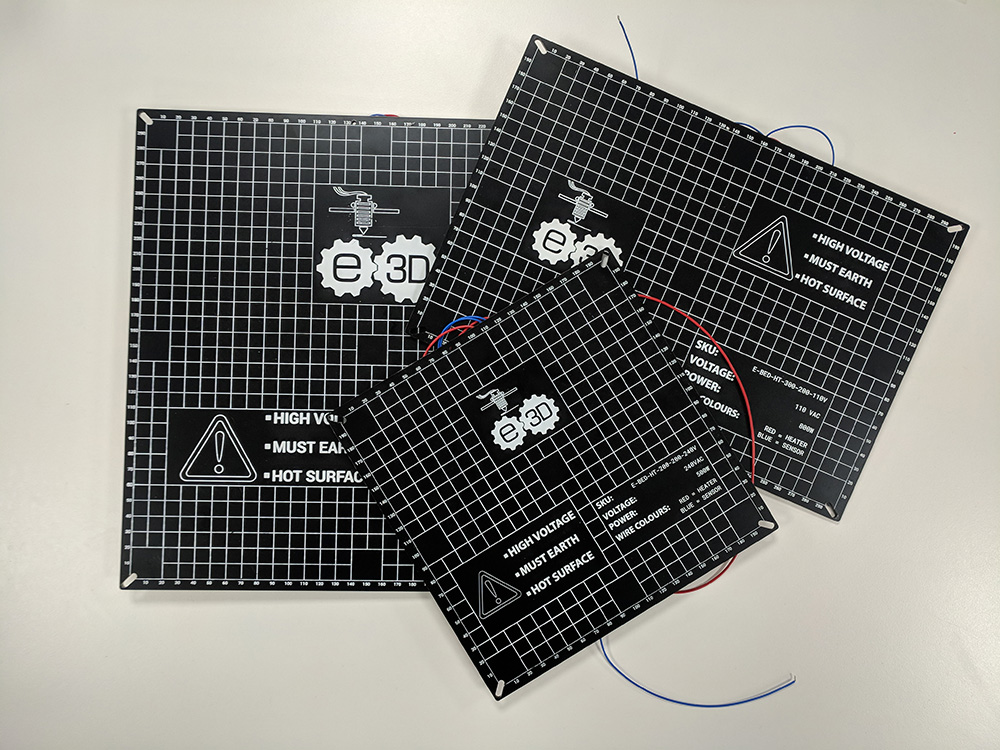

Furthermore, a high-temperature hotbed prevents warping of PAEK filament. The 3mm thick aluminum heated bed by E3D can reach 100°C within 80 seconds and continuously run at 200°C.

Currently, the two products are priced:

– High-temperature heater cartridges: £57.60 (incl. VAT)

– High temperature heated bed: £103-180 (incl. VAT)

PAEK for desktop 3D printers

As desktop 3D printers are not capable of reaching high extrusion temperatures, they are unable to print with PAEK or other engineering-grade filaments.

Another hurdle which bars accessibility to PAEK is the cost of high-grade polymer 3D printers, such as the 3DGence INDUSTRY F340 and miniFatory Ultra, both priced over £15,000.

But the 3D printing community has responded to such barriers. In 2016, a team of researchers, facilitated by NASA, modified the opensource Lulzbot Taz 4 to 3D print with high-temperature polymers. Along with other software and hardware modifications, LulzBot’s native hotend was replaced with E3D-v6 1.75 mm Universal. The refashioned printer was capable of printing with PEI (Polyetherimide).

E3D’s partnership with Victrex and the latest release of the high-temperature 3D printer components is another step in the direction of making PAEK affordable and accessible to the desktop 3D printing community.

For more news on the latest trends in 3D printing, subscribe to our 3D printing newsletter.

You can also follow us on social media: Facebook and Twitter.

Our 3D Printing Jobs has an exciting career path for you.

Featured image shows E3D’s latest high-temperature heating bed. Image via E3D-Online