DyeMansion, a manufacturer of cleaning and surface finishing systems for the 3D printing industry, has announced two new process innovations for its Powerfuse S system at RAPID + TCT 2021.

In addition to the new developments, which include compliance with the FDA’s food contact regulations and three ready-to-use parameter sets for various smoothing strengths, the company also announced the further expansion of its business in North America and provided an update on its ongoing alliance with 3D printer manufacturer Stratasys.

“We are currently seeing strong market growth in North America and are very pleased that we can now serve our American customers even better with our fully operational US office,” said Felix Ewald, Co-founder and CEO of DyeMansion. “With 11 people in our US team, our increasing number of sales and production partners and our new partnership with Stratasys we are well on our way to creating a colorful future.

“We are also very pleased to have Stratasys Direct Manufacturing as a workflow customer now and look forward to handling demanding high-volume projects together.”

Powerfuse S updates

DyeMansion’s Powerfuse S vapor polishing system delivers sealed, eco-friendly surfaces to parts that are suitable for a wide range of applications. The system’s hardware utilizes DyeMansion’s VaporFuse Surfacing technology and eco-friendly Vaporfuse Eco Fluid solvent to enable a sustainable contact-free process without chemical waste.

In September last year, the PowerFuse S was awarded funding from the European Innovation Council’s (EIC) “Green Deal” program to expand the capabilities of the technology and widen the process’ material compatibility.

Now, at RAPID + TCT 2021, DyeMansion has announced the VaporFuse Surfacing process is now compliant with the FDA’s food contact regulations, with its Eco Fluid solvent suitable for contact with all food types for which the base polymer is technically suited and authorized. The company showcased examples of such food contact applications at its booth at the show, one of which was a PA2201 part from Kuhn-Stoff GmbH & Co that is used in the production of cookies.

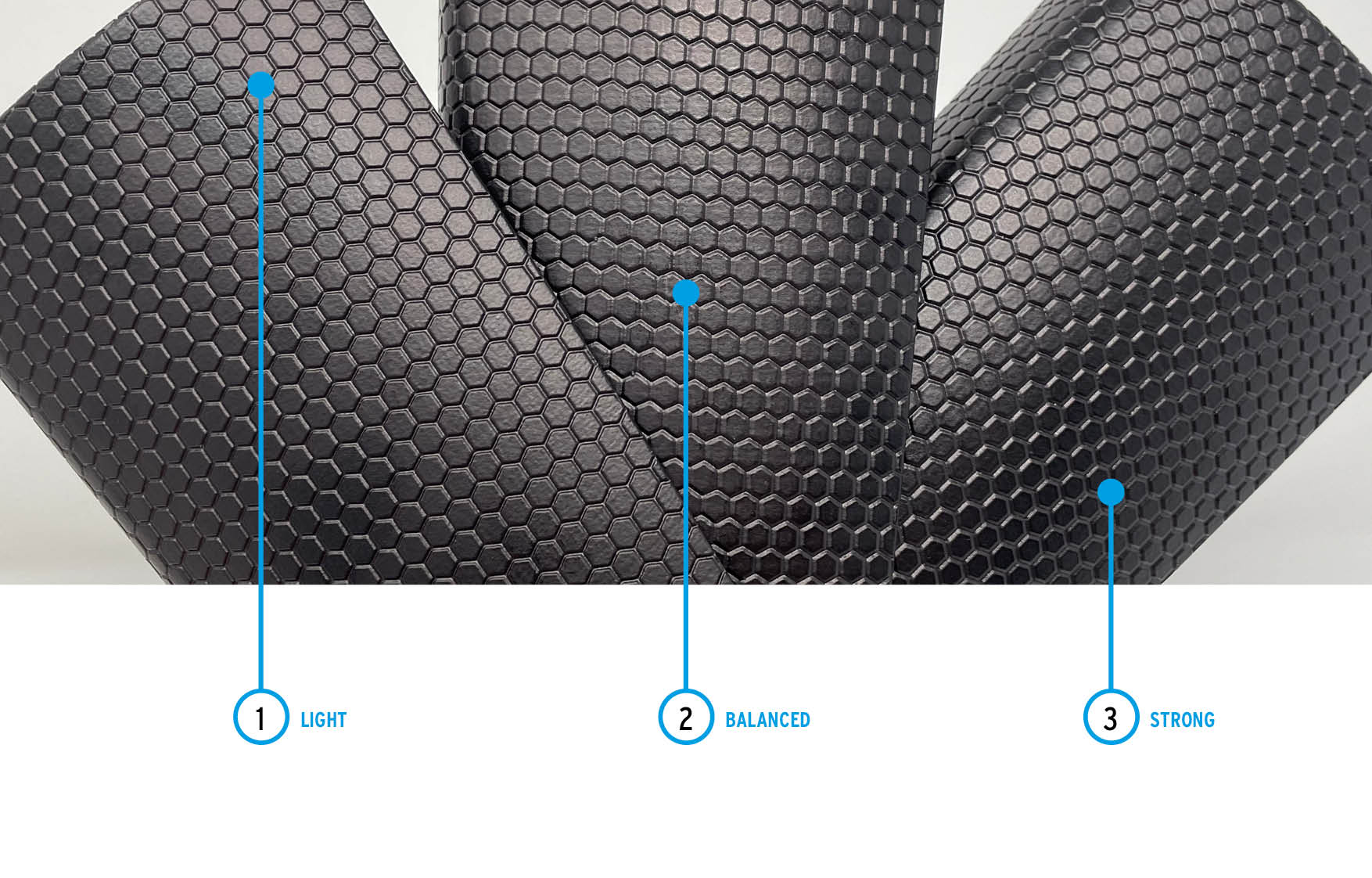

In addition to the Powerfuse S’ new food contact compliance status, the system has also been upgraded with three ready-to-use parameter sets for different levels of smoothing strengths. The new parameters, called “Levels of Smoothing”, fall under the categories Light, Balanced, and Strong, and can be adapted individually for the requirements of different applications.

According to DyeMansion, this makes the Powerfuse S the “most customizable and reliable vapor polishing system on the market”. The Levels of Smoothing are available to DyeMansion’s customers for materials including EOS PA 2200, EOS TPU 1301, HP 3D HR PA 11/12, and HP BASF Ultrasint TPU 01, with more to follow.

Vaporfuse surfacing of polypropylene parts

Alongside the new Vaporfuse S developments, DyeMansion has also announced the development of a bio-based and biodegradable solvent capable of vapor polishing polypropylene (PP) 3D printed parts.

The solvent is currently being validated with different PP materials, and has so far been successfully tested for Ricoh PP, HP Ultrasint PP, ALM PP400, VoxeljetPP, AM Polymers PP03, Ultimaker PP, EOS PP1101, and DSM ARNILENE AM6002.

The first results of the tests were showcased at DyeMansion’s RAPID booth, with applications for the pilot phase of testing the technology beginning in the middle of next year.

Expanding the Stratasys alliance

DyeMansion announced a strategic alliance with Stratasys in May earlier this year, resulting from joint efforts by the companies to evaluate the use of DyeMansion’s post-processing platform as a mass production solution within 3D printing workflows.

As a result, the developed Print-to-Product workflow can now be used with Stratasys’ H350 additive manufacturing platform, powered by selective absorption fusion (SAF) technology that utilizes the High Speed Sintering 3D printing process developed by Xaar.

Since initiating the partnership, DyeMansion has expanded its global partner platform with the gain of two new Illinois-headquartered authorized sales partners, Advanced Tech and CATi, who offer the firm’s post-processing products alongside Stratasys’ technology.

Subsequently, DyeMansion has experienced a rapid increase in demand for its industrial post-processing capabilities within the North American market, with a third of its 600 systems installed globally residing in the region. To meet this demand, the company has expanded its technology hub and operation center at its Austin site to include a production facility for consumables, and a warehouse for spare parts.

Stratasys’ service bureau operations Stratasys Direct Manufacturing is also currently expanding its post-processing capabilities at its Powder Bed Fusion (PBF) production site in Texas, with the addition of DyeMansion systems such as the Powershot S and DM60.

“We produce thousands of PBF parts per month, and our current DyeMansion equipment has become invaluable to processing components efficiently,” said Greg Reynolds, Vice President of Operations for Stratasys Direct. “Adding more DyeMansion capabilities to further enhance our capabilities was an easy decision. We look forward to introducing these improved finishes to our customers.”

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews and webinar replays.

Featured image shows DyeMansion and Stratasys are continuing to expand their strategic alliance. Photo via DyeMansion.