DyeMansion, a manufacturer of cleaning and surface finishing systems for the 3D printing industry, has announced the launch of three new post-processing systems.

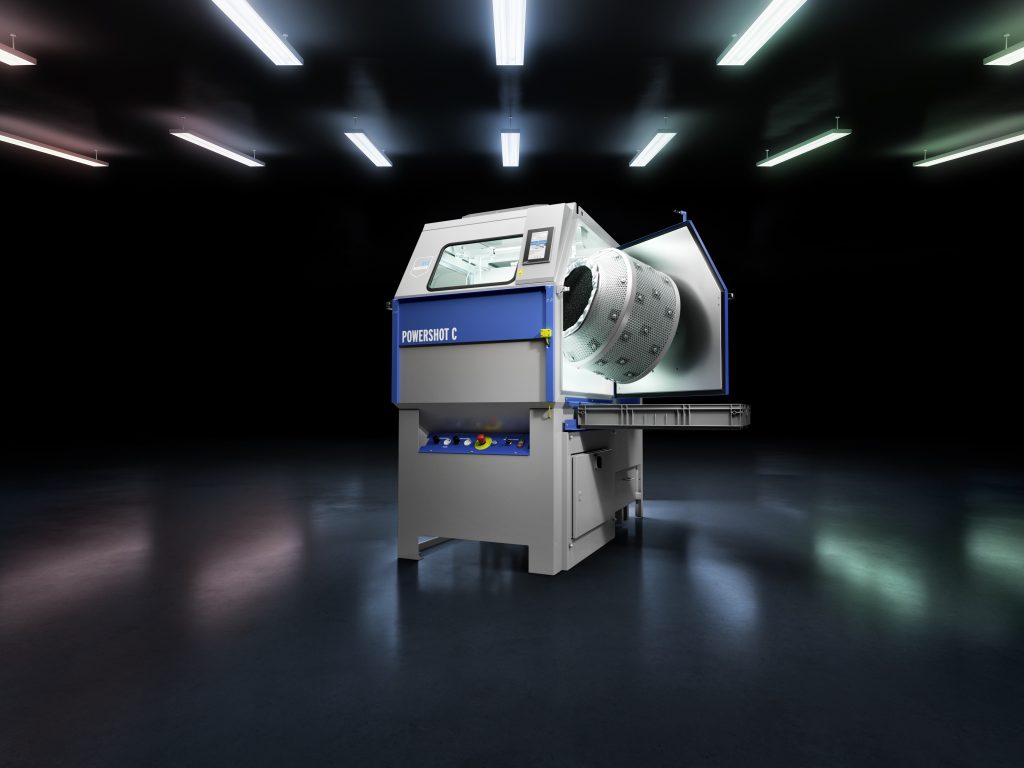

The new Powershot Performance series comprises the Powershot C Performance (cleaning), the Powershot S Performance (surfacing), and the Powershot DUAL Performance (cleaning and surfacing) – each of which is built to complement high-volume 3D printing on the shop floor.

Felix Ewald, CEO and Co-founder of DyeMansion, explains, “With the new generation of our classic Powershot C & S models, the best products in their segment just got even better. As we truly believe in the industrialization of Additive Manufacturing, we came up with another solution for industrial and high-volume applications: our new Powershot Performance series. Now the time has come for 3D printing to enter the next era, as we’ve accomplished another big step in post-processing.”

Supporting the industrialization of additive manufacturing

Automated post-processing systems have historically lagged behind 3D printers in terms of technological advancement, rendering them a bottleneck in the road to industrialization. DyeMansion is looking to change this with the development of high-throughput cleaning and surface finishing devices for industrial components.

Compared to the original models, the new Powershot C and S Performance systems reduce process times by an average of 20%, increase load capacity by an average of 150%, and improve overall ease-of-use. Designed for a wide range of industrial polymer components, the new systems are capable of processing full-sized build jobs from large-format 3D printers such as the EOS P396 or the HP Jet Fusion 4200/5200. The Powershot DUAL Performance is also the first time DyeMansion has ever combined cleaning and surfacing functionality in a single system.

Much like DyeMansion’s existing vapor polishing system, the Powerfuse S, the new Performance range comes complete with automation technology developed by tech giant Siemens. Karsten Heuser, VP of Additive Manufacturing at Siemens Digital Industries, adds, “The Powershot Performance series marks the next milestone in the strategic partnership between DyeMansion and Siemens towards industrialized Additive Manufacturing.”

The new PolyShot Cleaning process

Looking specifically at the new C and DUAL Performance machines, DyeMansion has integrated a newly developed PolyShot Cleaning process for improved results. The proprietary process makes use of an optimized polymer blasting medium, rather than industry-standard glass beads, with the shape, size, and weight necessary to gently remove loose powder from full-color 3D printed parts.

The process is residue-free and ensures there is no mineral dust left on part surfaces. According to DyeMansion, it is compatible with all common powder-based 3D printing technologies and even works with challenging process materials such as TPU.

“A machine itself does not solve customer problems, which is why we have put such a big focus on the development of the right processes,” says Philipp Kramer, CTO & Co-founder of DyeMansion. “By combining the right machines with the right processes, we have created a solution. The new PolyShot Cleaning process is enabled by a blasting media that was developed from ground up to perfectly match the requirements of depowdering 3D printed parts.”

The newly announced Powershot Performance series will initially be available to a select group of pilot customers, with commercial orders set to be accepted from Q4 2021 onwards.

With ongoing advancements in automated post-processing technology, additive manufacturing edges ever closer to true industrialization. Earlier this month, UK-based post-processing specialist Additive Manufacturing Technologies (AMT) closed a £2.5 million funding round, bringing the total amount raised by the company to more than £7 million. AMT will use the funding to further develop its chemical vapor smoothing process, PostPro.

Elsewhere, post-printing system manufacturer PostProcess Technologies was recently granted a U.S. patent for its Volumetric Velocity Dispersion (VVD) technology. The company’s spray-based support removal process is featured in PostProcess’ BASE and DECI systems, and works primarily with FDM, SLA, CLIP, and PolyJet 3D printed polymer parts.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the new Powershot Performance series. Photo via DyeMansion.