Domestic Data Streamers, an independent data design studio based in Barcelona, used BCN3D Technologies 3D printers to create its interactive installation for the Cisco Live 2020 event earlier this year.

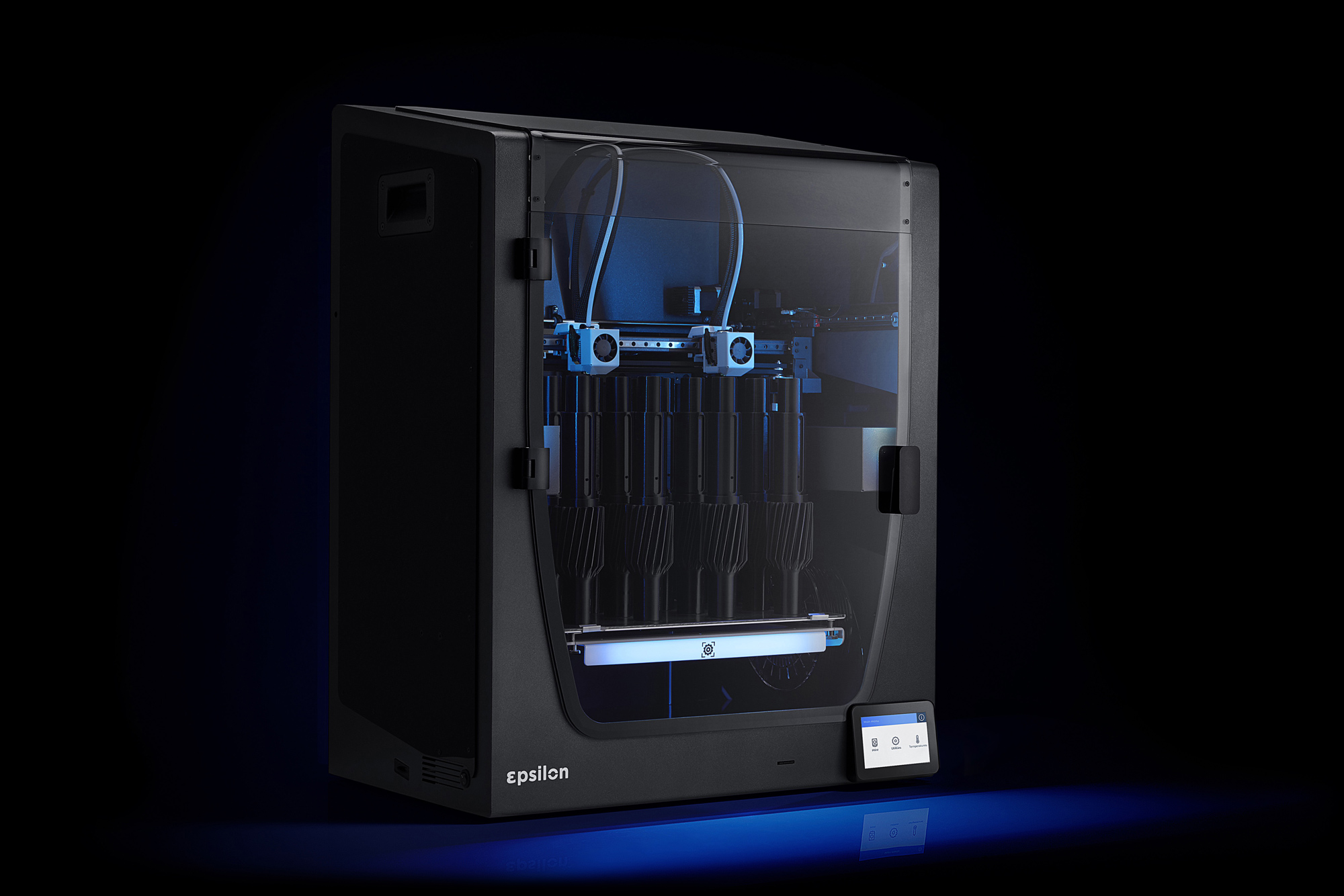

Using the BCN3D Epsilon, the creative studio was able to design, produce and set up its Recommendation Wall installation within 4 weeks, in time for the event which took place in January 2020 in Barcelona with over 15,000 visitors.

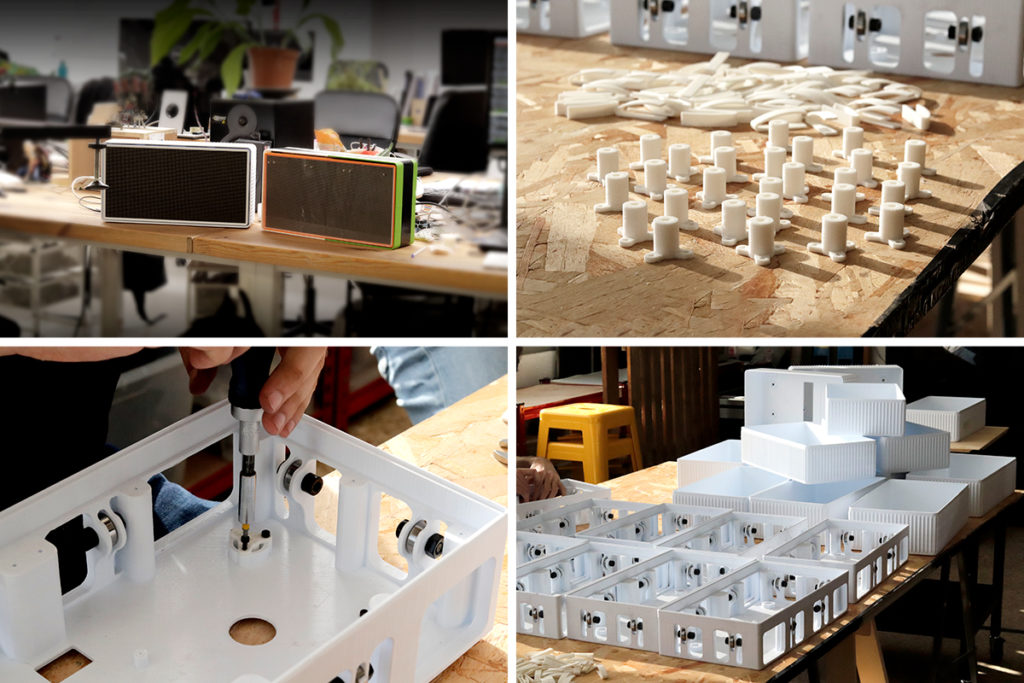

The wall, featuring clickable screens, allows visitors to interact with it to gain useful information about Cisco Live. The team at Domestic Data Streamers found that 3D printing was the ideal solution for prototyping and iterating the custom made clickable screens.

Pol Trias, Head of Design at Domestic Data Streamers, explains “This could not have happened without 3D printing.”

“For a project like this one, where you want high-quality results in a short time and within a limited budget, there is no better option than 3D printing.”

Creating interactive installations with 3D printing

Founded in 2013, the mission statement of Domestic Data Streamers is to “[Create] meaningful connections between data and audiences”, according to Trias. The studio combines storytelling with data and arts to enable an interchange of information, in a bid “to create participatory projects that build community, educate, communicate, and drive change”.

An office of researchers, designers, coders, and strategists, Domestic Data Streamers has partnered with over 130 partners throughout the world, including the United Nations and Unicef, Google, BuzzFeed, and Spotify. For these clients, the studio has created interactive projects for their audiences in more than 17 countries.

Helping to build its interactive installations, the Domestic Data Streamers workshop “has been using BCN3D printers since the very beginning”, confirms Trias, “the printers work very well, we count on a very high success ratio, and the support from the team is always quick and helpful”.

As most of the company’s unique installations combine architecture, interactive data dashboards and visual, space, product, and sound design, there are many cases whereby components had to be designed and fabricated on demand. It is in these instances that Domestic Data Streamers has leveraged 3D printing in its projects.

At Cisco Live 2020, Domestic Data Streamers was tasked with creating an interactive display of the event’s schedule; in other words, a wall of clickable screens showcasing the daily agenda. Visitors would click scheduled events of interest, where the animated image would then turn into QR code which could be then scanned for more information.

Although the wall structure itself could be easily made using pre-existing objects, Domestic Data Streamers found that the clickable screens had to be custom made. “As a clickable button, there is a lot of mechanics involved,” explains Trias. With a lot of iteration required for the components, and a short amount of time to complete the project, the Domestic Data Streamers team turned to its internal BCN3D Epsilon 3D printing system.

Using the Epsilon, the design studio was able to produce a number of prototypes and iterate the design of the clickable screen within a 4 week period. Over 40 of the main covers, excluding the internal components, were 3D printed in PET-G before being set up at Cisco Live 2020. “Domestic Data Streamers is a very dynamic company. We are always coming up with new ideas, and this flow is what 3D printing provides us, the ability to quickly physicalize all the ideas that we have every day”, concludes Trias.

BCN3D dual extrusion technology

BCN3D is a Barcelona-based desktop 3D printer manufacturer originally founded in 2012, stemming from a research group at the Polytechnic University of Catalonia’s (UPC) additive manufacturing division, the CIM-UPC center.

The company released the Epsilon, its latest FFF/FDM system, in November 2019. Equipped with dual-extrusion capabilities, the Epsilon is intended for more demanding settings compared to its previous range of desktop 3D printers. Featuring a 420 x 300 x 400 mm build volume, it is designed to provide large-scale FFF 3D printed parts with high-performing materials.

Earlier that year, BCN3D had raised $3 million in seed funding, and subsequently established itself as an independent company separate from UPC. The company has experienced success with its Sigma range of 3D printers, which includes the Sigma R19 and the Sigmax R19 FFF dual extruder systems. Both use the BCN3D’s Independent Dual Extruder (IDEX) technology which allows users the freedom of two new print modes: Duplication Mode and Mirror Mode.

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows 3D printing the clickable screen panels. Photo via BCN3D.