The US Department of Energy (DOE)’s Office of Fossil Energy has announced $6 million in federal funding for various research and development projects focused on the advanced processing of coal waste into 3D printable materials.

Working within the Advanced Coal Processing Program (ACP) at the National Energy Technology Laboratory (NETL), funding applicants will seek to extract the full economic value of coal waste by producing valuable products that support novel technologies, such as 3D printable materials for additive manufacturing.

According to NETL, the use of coal waste for 3D printing and graphite production aligns with the goals of President Biden’s administration, which is aiming to expand and develop environmentally-friendly uses for coal waste that can be deployed in economically-distressed communities.

Repurposing coal waste

As a critical domestic resource, coal has contributed to US economic growth for more than a century. However, as countries look to clean up their energy generation activities there is an opportunity for innovative technologies to transform the coal value chain and extract its full economic value.

The ACP has been initiated to take on this challenge, and its main goal is to utilize novel technologies to produce valuable products from coal-derived sources through laboratory and pilot-scale R&D.

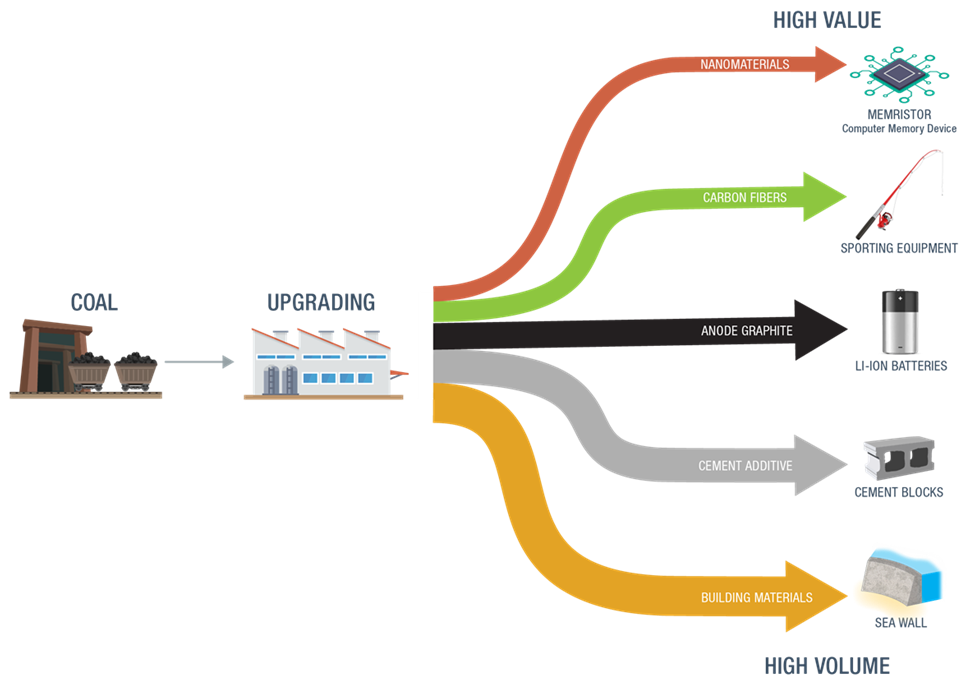

According to NETL, coal’s unique structure and composition makes it well-suited as a feedstock for high-value carbon products such as computer memory devices, carbon composites, and carbon-containing anodes for batteries. The abundance of the material, and its low cost, also make it attractive as a feedstock for high-volume applications such as building materials.

Both coal from existing mines and coal waste such as tailings and ash are acceptable feedstocks for the 3D printing of these applications, although waste is preferred.

As the US transitions to clean energy, the strategy intends to encourage job creation and prevent the cost of this transition from being disproportionately felt by coal and power plant communities.

The funding opportunity announcement

Titled ‘Advanced Coal Waste Processing: Production of Coal-enhanced Filaments of Resins for Advanced Manufacturing and Research and Development of Coal-Derived Graphite’, the program is looking to award funding to a maximum of six applicants.

Applications for two areas of interest are currently being sought, the first of which focuses on coal-enhanced filaments or resins for additive manufacturing. R&D efforts in this area will see the development of coal-enhanced filaments and resins with superior properties or economic benefits for 3D printing, using either fused deposition modeling (FDM) or stereolithography (SLA) technologies.

The second area of interest will look at developing pathways for the economical production of coal-derived graphite that could be used in applications such as battery anodes, bipolar plates for proton exchange membrane fuel cells, supercapacitor electrodes, substrates for carbon composites, and lubricants.

Those looking to attain the DOE funding will need to submit a summary of the environmental considerations regarding their proposed technology and outline how it will mitigate the environmental impacts of coal use. Applications must be submitted by May 31, 2021.

Repurposing waste in additive manufacturing

Countries and industries around the world are increasingly looking to accelerate the transition to cleaner and greener energy, and improving sustainability within 3D printing processes and technologies is also undergoing continual development.

For instance, EU-funded project NOVUM is aiming to address global issues surrounding resource sufficiency, climate change, and the circular economy by exploring cellulose as a substitute for fossil-based materials. Part of the Horizon 2020 program, the project is made up of 10 different partners spanning various levels of the value chain which will develop cellulose-base material optimized for the 3D printing of automotive, marine, and electrical insulation applications.

Waste sources have previously been repurposed to produce 3D printing materials in Horizon 2020 projects, such as BARBARA, which last year concluded four years of research into developing new 3D printable materials from food waste and agricultural by-products such as pomegranate, lemon, almond shell, and corn. A total of eight new bio-based materials were successfully developed during the project, and the next step for the team will be to scale up prototypes from the lab to semi-industrial level.

Elsewhere, the University of Louisville’s Conn Center for Renewable Energy Research is currently developing a process that transforms soy hulls left over from soybean processing into 3D printable materials. These materials could have potential uses within industries that rely on petroleum-based fiberglass and carbon fiber composites to reduce weight and maintain strength, such as the automotive and aerospace sectors.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows both coal from existing mines and coal waste such as tailings and ash are acceptable feedstocks for 3D printing applications during the ACP.