Robotics start-up Diamond Age has raised $50 million in a Series A funding round to accelerate the development of its robotic 3D printing construction system.

The firm is seeking to leverage 3D printing and automated robotics to offset more than half of the manual labor required to build a new home, and reduce construction cycle times from nine months to just 30 days.

“Affordable housing is impacting people on a global scale,” said Jack Oslan, Founder and CEO of Diamond Age. “As the average age for first-time homebuyers has moved from mid-twenties to mid-thirties, there’s an increased demand for more rental property – forcing the entire hierarchy of renters into a more competitive market for ‘quality’ housing.

“Helping the next generation of homebuyers get into their first house faster helps the entire ecosystem of housing.”

Diamond Age, robotics and 3D printing

Diamond Age was founded in order to address the US housing market’s single-family home shortage of almost seven million through reducing the construction cycle time of building new homes.

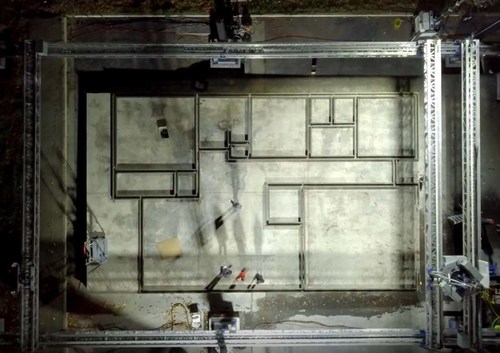

The firm is building a suite of 26 end-of-arm robotic tools with 3D printing capabilities that move along a gantry system to print the interior and exterior walls of a house. The firm’s Robotic-as-a-Service (RaaS) system comprises 3D printing, mechatronics, and robotics in order to automate the process of building new homes.

Since raising $8 million in seed funding in August last year, the company has scaled up the build envelope of its robotic 3D printing system to fabricate a 2,000 square foot single-story home. The firm delivered the first scaled version of its system in addition to a full-scale three-bedroom, two-bathroom house in 11 months, four months ahead of schedule.

Off the back of this success, Diamond Age has secured its first contract with a national homebuilder, which will be announced over the next few days.

Addressing the US’ affordable homes crisis

Diamond Age has raised a significant sum of $50 million upon closing its Series A funding round, taking the total funding raised by the firm to date to $58 million. The funding round was led by scientific start-up investor Prime Movers Lab, which also led the firm’s seed funding round last year.

Previous investors Alpaca VC, Dolby Family Ventures, Timber Grove Ventures and Gaingels all participated in the round, joined by new investor Signia Venture Partners. 20 percent of the funding round was also made up of production home builders and land developers.

Diamond Age will use the latest capital injection to continue scaling its robotics platform and carry out its first commercial home building contract. The company has already doubled in size since its founding and plans to bring more engineering talent on board to continue delivering on its aims.

In turn, the company hopes growing its workforce will help it partner with home builders and developers in order to “turn home building into an on-demand product” and ultimately provide buyers with more options to customize and personalize their own homes.

“Diamond Age’s Factory in the Field system brings automation to the construction site to backfill the massive labor shortage in the home construction system,” said Suzanne Fletcher, a General Partner at Prime Movers Lab.

“Jack and his team have hit key milestones ahead of schedule and are transforming the way production homes are constructed so it was an easy decision for Prime Movers Lab to lead the company’s Series A.”

3D printing cheaper, faster homes

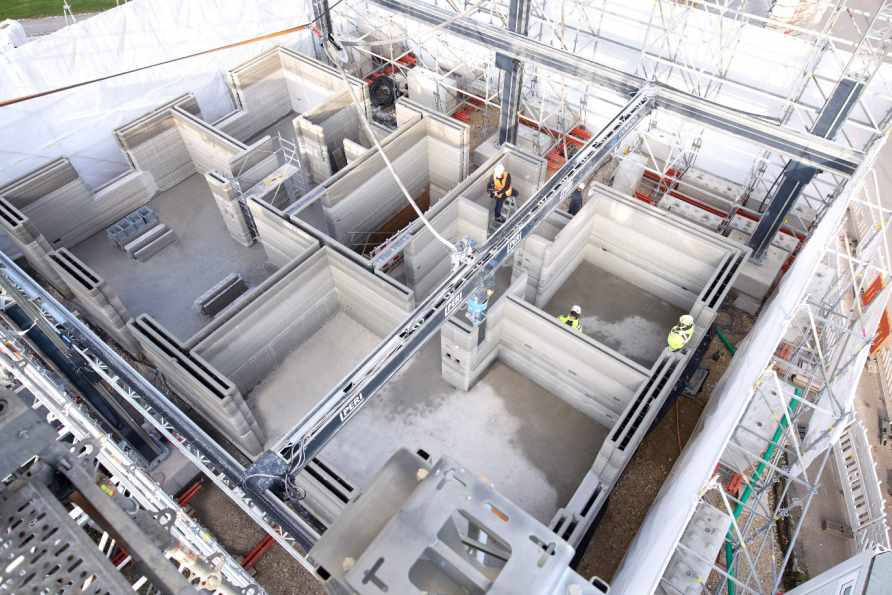

Since construction firm PERI Group announced it had begun building the “world’s first” 3D printed commercial apartment building back in 2020, multiple projects have deployed additive manufacturing to fabricate commercial homes and accommodation.

For instance, LafargeHolcim’s Zimbabwean subsidiary has announced plans to build affordable, low-carbon homes in the country using its concrete 3D printing approach, while Dutch building firm CyBe Construction has begun working with concrete specialist Betonindustrie Brievengat (BIB) to build its first 3D printed homes in the Caribbean.

In October, Texas 3D printing firm ICON announced it was building the largest community of 3D printed homes to date in Austin, Texas, after listing its first 3D printed homes on the US’ domestic housing market last March.

More recently, construction 3D printer manufacturer COBOD’s systems have been used to create three new low-cost homes for those living in the rural US, and construction 3D printing firm Azure Printed Homes has been given a contract to deliver 14 3D printed prefabricated homes in Ridgecrest, California, made entirely from recycled plastic.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews and webinar replays.

Featured image shows Diamond Age’s robotic 3D printing gantry system. Photo via Diamond Age.