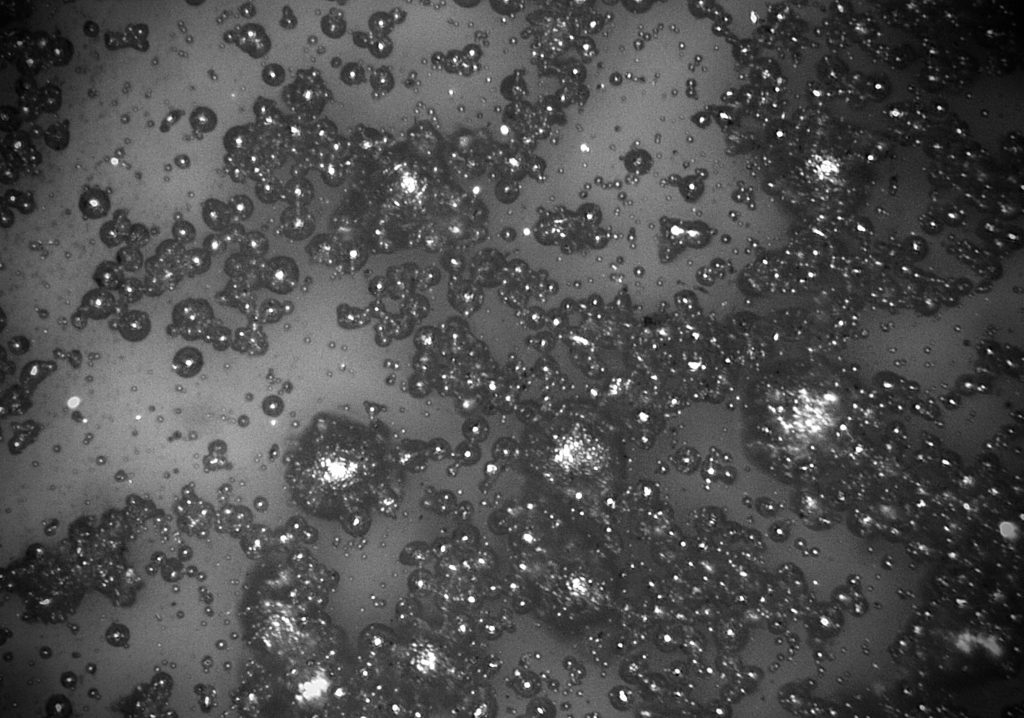

3D printer manufacturer Desktop Metal, together with materials developer Uniformity Labs, has announced the launch of a new sinterable aluminum powder for use with the company’s binder jet 3D printing technology.

Developed as the result of a multi-year partnership between the firms, the new powder is named Uniformity 6061. It is intended as a low-cost raw material option for manufacturers looking to 3D print fully dense, sinterable 6061 aluminum alloy parts. According to Desktop Metal, the material features an elongation greater than 10% and provides both an improved yield strength and an improved ultimate tensile strength when compared to wrought 6061 aluminum with similar heat treatments.

Ric Fulop, CEO and co-founder of Desktop Metal, states, “This breakthrough represents a major milestone in the development of aluminum for binder jetting and a significant step forward for the AM industry as it is one of the most sought-after materials for use in automotive, aerospace and consumer electronics. The global aluminum castings market is more than $50 billion per year, and it is ripe for disruption with binder jetting AM solutions.”

What makes Uniformity 6061 aluminum unique?

Desktop Metal’s latest material enables users to sinter 3D printed 6061 aluminum parts without first having to make any additions or infusions. As such, it is a significant improvement over many of the techniques used to sinter aluminum parts today, which include coating the powder particles, mixing in sintering aids, using binders that contain costly nanoparticles, and adding additional metals such as lead, tin, or magnesium.

Furthermore, Uniformity 6061 aluminum is also compatible with water-based binders and offers a higher minimum ignition energy (MIE) when compared to comparable commercially available 6061 powders, making it safer to use. The material is expected to unlock a wide variety of applications, including electrical fittings, heat exchangers, vehicle frames, and coupling components.

“The introduction of lightweight metals to binder jetting opens the door to a wide variety of thermal and structural applications across industries,” adds Adam Hopkins, founder and CEO of Uniformity Labs. “This innovation is a key step towards the adoption of mass-produced printed aluminum parts.”

A new option for Production System customers

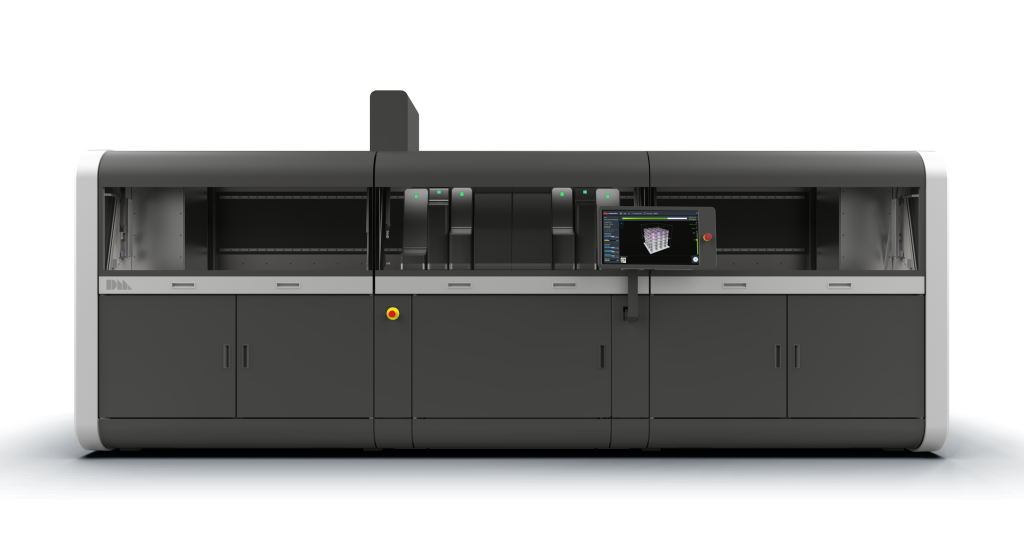

The companies will continue working together over the next year to qualify the powder and scale its production for a commercial launch. Once qualified, 6061 will be available to use with Desktop Metal’s Production System 3D printer. The industrial machine features an inert, chemically inactive build chamber and an auxiliary powder processing system, making it perfectly suited to 3D print reactive metals such as aluminum.

Fulop adds, “These are the best reported properties we are aware of for a sintered 6061 aluminum powder, and we are excited to make this material available exclusively to Desktop Metal customers as part of our ongoing partnership with Uniformity Labs.”

As well as a number of recent material launches, Desktop Metal has been making major moves in other aspects of its business. Back in December, the company merged with blank check firm Trine Acquisition and went live on the New York Stock Exchange (NYSE). The deal valued the combined entities at around $2.5 billion, providing Desktop Metal with $580 million in funding.

Following the public launch, Desktop Metal also signed a $300 million definitive agreement to acquire DLP 3D printer OEM EnvisionTEC. The cash-plus-stock deal concluded in February 2021, and EnvisionTEC is now a wholly-owned subsidiary of Desktop Metal.

Just last month, the company also launched its Studio System 2 metal 3D printer. Powered by the company’s proprietary Bound Metal Deposition (BMD) process, the new Studio System 2 is based on the previously released Studio System+, an office-friendly machine intended for low-volume prototyping and custom end-use production.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the new Uniformity 6061 aluminum powder. Image via Desktop Metal.