Carbon, a leading 3D printing technology business, has a new production option to 3D print clear aligners for the dental 3D printing sector.

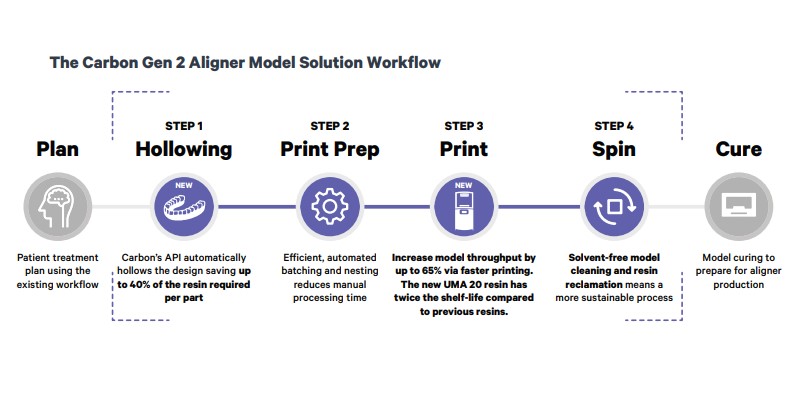

Announced at the International Dental Show this week, the sustainability-orientated production solution offers significant cost savings, with up to a 65% increase in throughput and less material required per print. This reduces the cost per part considerably while boosting throughput. The Carbon Gen 2 aligner model solution comprises new proprietary software and high-performance resin that works with Carbon’s existing 3D printing systems and aligner model workflow.

“Working with the top clear aligner companies has given us insight into the barriers this industry faces on a daily basis. We heard from customers, and we took action to create efficiencies and cost savings in the clear aligner workflow,” said Terri Capriolo, Senior Vice President, Oral Health at Carbon. “This new aligner workflow is designed to enable Carbon customers to reduce cost per part while simultaneously improving model throughput with a more sustainable production process.”

The Carbon Gen 2 aligner model solution will be available to customers in the second half of 2023.

A workflow for dental 3D printing

The Gen 2 aligner model solution will provide new and existing clients with integration to Carbon’s existing clear aligner workflow, used by major aligner manufacturers to make millions of custom clear aligners each month worldwide. The dental 3D printing solution includes the Carbon L1 printer, a solventless spin-cleaning solution, and API-based software that automates the hollowing, nesting, and batching of 3D printed models. Carbon’s new production solution automatically hollows models with software tools and, coupled with Carbon’s UMA 20 resin, provides a novel method that delivers a cost-effective and sustainable option for transparent aligner producers.

The Gen 2 aligner model solution provides aligner manufacturers with innovations while leveraging their existing Carbon subscription and may result in reduced costs per part, improved throughout, and increased sustainability. Cost per part is reduced by boosting throughput while decreasing resin usage per part. According to Carbon tests, fully automated hollowing saves up to 40% of resin for every item. Based on Carbon testing, improved throughput via the automated hollowing software, combined with the UMA 20 resin, increases component throughput by up to 65%. Solvent-free model cleaning eliminates solvent waste and allows the resin to be reused, leading to increased sustainability.

Advances in the dental 3D printing sector

Candid, an orthodontics company, joined forces with Carbon to produce highly-customized clear dental aligner models using Carbon’s resin-based digital light synthesis (DLS) technology and L1 3D printers. This collaboration led to Candid’s new offering, called Candid Pro, which provides an “orthodontics-as-a-service” solution for dental professionals and orthodontic practices seeking to scale up their patient base while outsourcing aligner manufacturing work.

Carbon’s Phil DeSimone expressed his pride in partnering with Candid to produce the best-fitting aligners at scale. This new production process will enable clinicians to deliver affordable and effective patient treatment.

Candid Pro is an end-to-end solution designed by Dr. Lynn Hurst, co-founder of Candid. The service utilizes Candid’s network of orthodontists to create personalized treatment plans for each patient. Dental clinicians need only initiate the case, and Candid’s clinical care team and technical experts take care of the rest using 3D medical scans provided by the customer. The Candid App allows for transparency, allowing customers to monitor their patient’s progress remotely and minimize the number of office visits required.

Carbon’s L1 production system is a crucial part of the Candid Pro process, as it enables Candid to produce millions of highly-accurate aligner models with efficiency and reliability. This partnership allows Candid to offer bespoke solutions for each patient at scale. DeSimone said this is a significant step forward in the dental industry.

3D printing is also enabling innovation in the dental aligner market. Researchers from Germany, Egypt, and the UAE have developed a 3D printed dental aligner with “4D” shape memory capabilities, potentially making it an alternative to single-use dental products. The orthodontic device, made from Kline Europe’s transparent ClearX resin, softens once inserted into a user’s mouth, allowing it to grip and reposition misaligned teeth. It has been proven to predictably change its properties over time and offers a more comfortable way of repositioning teeth than traditional braces. The researchers suggest that shape memory polymers could help address the speed “shortcomings of conventional materials.”

Polymers are not the only 3D printable material with dentistry applications. High-performance 3D printed ceramics have massive potential for various applications, including machinery, electronics, space, medicine, and dentistry. Lithoz CEO Johannes Homa says that ceramics are often overlooked in 3D printing but have the potential to become abundant.

Lithoz has worked with medical practitioners since 2017 and has several bone replacement materials available, including the recently developed Lithabone HA 480, which has improved wall thickness, biocompatibility, and geometry flexibility. Lithoz developed this material to meet the needs of surgeons and practitioners who wanted a broader range of applications, including the ability to 3D print large cranium replacement implants and closed surfaces where soft materials can grow. Longer-term outcomes of using Lithoz’s materials are expected to be reported in the coming years.

What does the future of 3D printing for the next ten years hold?

What engineering challenges will need to be tackled in the additive manufacturing sector in the coming decade?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Carbon’s L1 3D printer. Photo via Carbon.