3D Printing Industry recently attended the launch of SOLIDWORKS 2018.

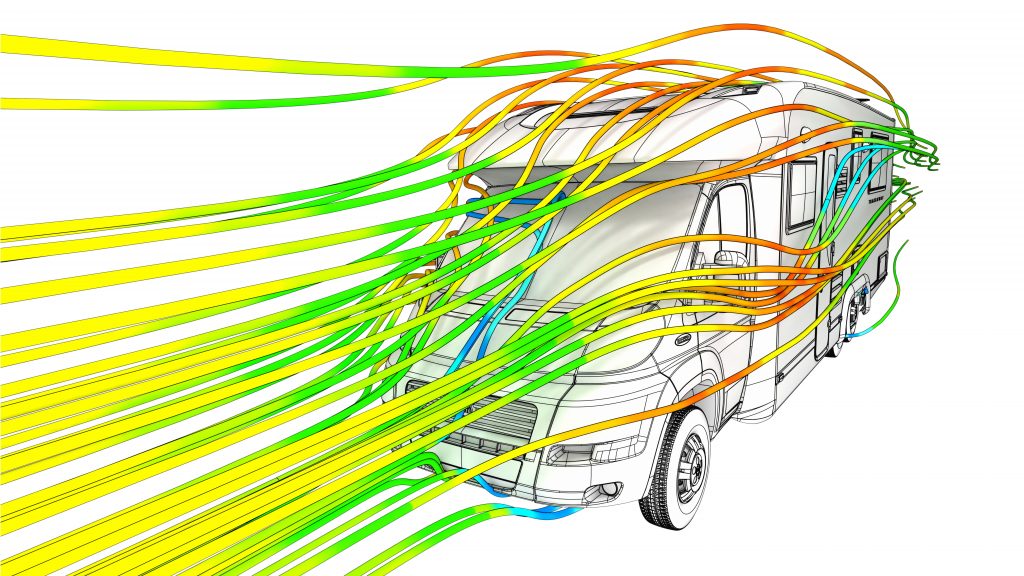

The new release of the 3D design and engineering software aims to integrate design into the manufacturing process. With a simplified product development workflow, Dassault Systèmes (Euronext Paris: #13065, DSY.PA) believes users with be able to innovate faster with improved business outcomes.

For a better insight into the 2018 version of SOLIDWORKS we sent a reporter with 6+ years experience of working with previous versions of the software to give their opinion.

A go-to CAD program

“SOLIDWORKS is my go-to CAD program. However for over the past six or so years of using SOLIDWORKS I have never truly seen a vital necessity to update my program” says mechanical engineer Evan Johannigman. “Coming out from the presentation, it was made absolutely clear to me how this year would have to be why I changed my mindset. SOLIDWORKS 2018 has listened to their user’s thoughts and ideas and has implemented solutions to help save Engineers hours of work while giving full control to the user so that they may continue to have free reign on designing solutions.”

Edson Gebo, Owner, Digital Detail & Design, said, “Lots of designs involve welding plate and sheet metal parts and most people use ‘tab and slot’ techniques for self-fixturing the parts for welding. The new tab and slot feature saves a lot of time versus having to create these features manually. This will really help get designs to the shop faster.”

We understand that Dassault Systèmes will roll out additional new end-to-end process solutions gradually.

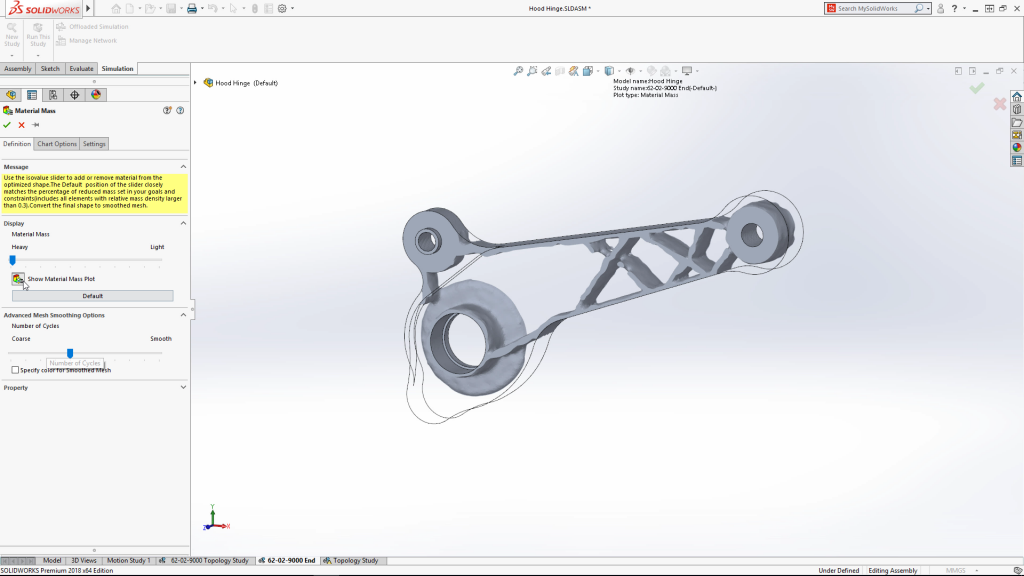

Johannigman says that the main feature that truly impressed him was Topology Optimization. “An engineer’s job is not only to provide innovative solutions to problems, but to also make sure they are profitable. This means choosing the correct material, the correct amount of material, and the correct process for it to be made. SOLIDWORKS’ Topology is able to complete two of these three requirements in about an hour.”

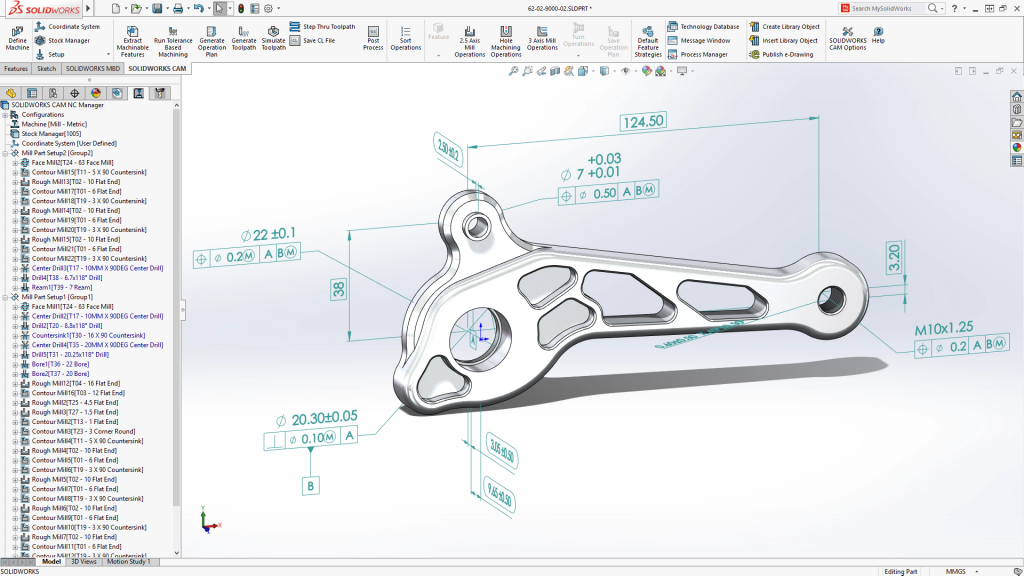

SOLIDWORKS CAM

In beta since April, and new for SOLIDWORKS 2018, is SOLIDWORKS CAM. This application provides rules-based machining with knowledge capture. It is intended to permit automation of manufacturing programming. The tool is intended to allow designers and engineers to “gain a greater understanding of how their designs are made, make more informed decisions, and quickly create prototype parts and manufacture in-house to control quality, cost and delivery.”

SOLIDWORKS CAM can be used by teams to execute new “build to order” strategies with custom parts that are automatically designed and programmed “in seconds rather than hours”.

Gian Paolo Bassi, CEO, SOLIDWORKS, Dassault Systèmes, said, “A successful consumer experience must have a well-designed product at its core and an efficient way to produce it. SOLIDWORKS 2018 brings more than just a smarter approach to manufacturing parts or products, it helps businesses translate imagination into innovation and build ecosystems.”

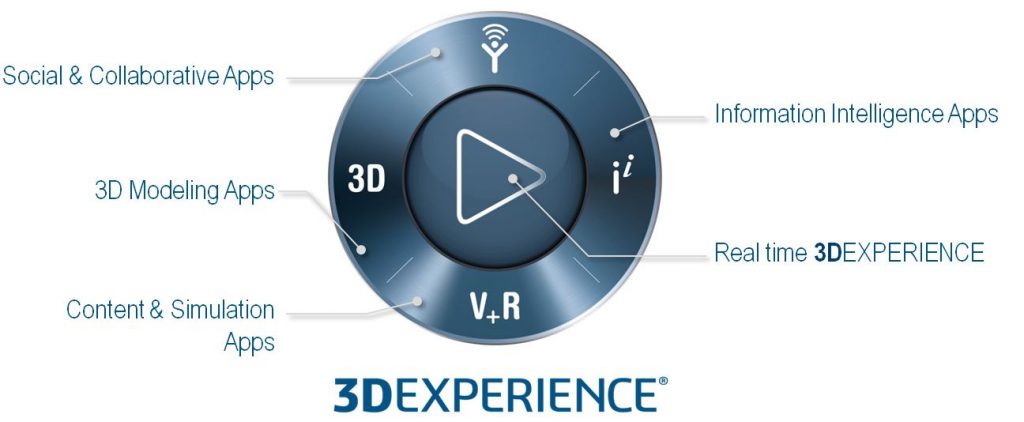

What is 3DEXPERIENCE?

One such ecosystem is the 3DEXPERIENCE ‘portfolio’ that powers SOLIDWORKS 2018. Defining what 3DEXPERIENCE is not an easy task, as the marketing messages from DS are seemingly lost in translation. Having attended DS events in Milan and London this year, I am still not entirely certain what 3DEXPERIENCE is. It appears to be the suite of software offered by DS – but this seems rather reductionist compared to the possibilities envisioned during the high production value events.

In giving his perspective on the future of 3D printing Stephen Chadwick, Managing Director EuroNorth at Dassault Systèmes, describes how through, “a unified business platform companies will reap the productivity benefits delivered through an end-to-end solution, including all engineering parameters, for the additive manufacturing of parts inclusive of material science, functional specification, generative design, 3D printing optimization, multi-robotic production and certification. When it is run on a seamless unified platform that builds bridges between skills, the advantages and benefits of AM technology are multiplied.”

Going back to our visiting engineer and back to practical use, Evan Johannigman sees the time savings enabled by SOLIDWORKS 2018 as the most appealing reason to upgrade. Especially for “any Engineer that deals with material design, kinetic interactions, or a combination of both.”

For all the latest updates on additive manufacturing software, subscribe to our free 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.