Siemens, the Georgia Institute of Technology, Michigan State University (MSU) and PARC have been chosen to work on DARPA’s TRAansformative DESign (TRADES) research program.

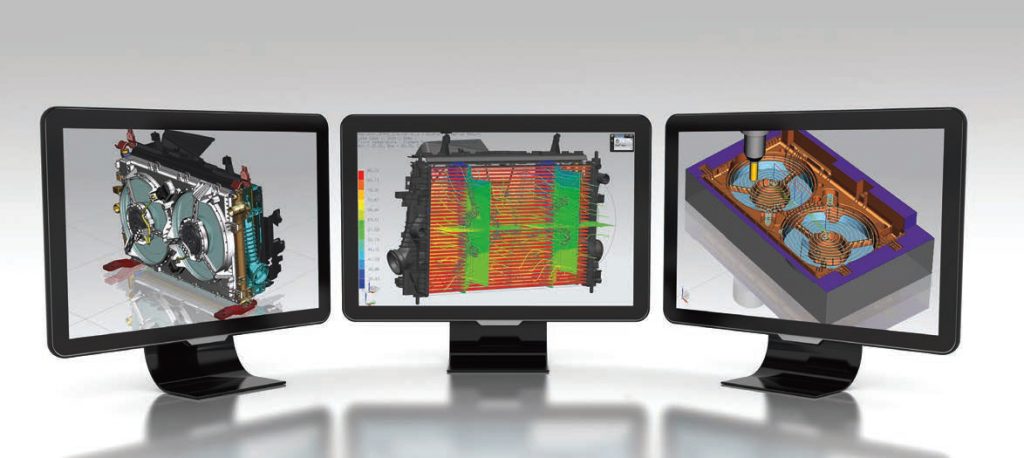

The goal of TRADES is to develop a new digital modeling program that expands the limits of current computer aided design (CAD). TRADES technology will facilitate the creation of more complex objects, optimized for rapid “design-to-manufacturing” through 3D printing and other digital techniques.

“We have reached the fundamental limits of computer-aided design”

An expansion to the capabilities of CAD was first realized in 2016, when DARPA sent out a call for research proposals for the TRADES project. Speaking at the time of this launch, Jan Vandenbrande, DARPA program manager, explained the necessity for such developments,

We have reached the fundamental limits of what our computer-aided design tools and processes can handle, and need revolutionary new tools that can take requirements from a human designer and propose radically new concepts, shapes and structures that would likely never be conceived by even our best design programs today, much less by a human alone.

Now proposals have closed, Siemens NX™ software has been chosen the base platform for expansion.

Billions of geometries rendered in a simple platform

NX is Siemens’ product lifecycle management (PLM) platform designed to streamline the production process from initial mock ups to final part production. It is pre-programmed to work with a range of materials and composites, and has specific tools integrated for additive manufacturing.

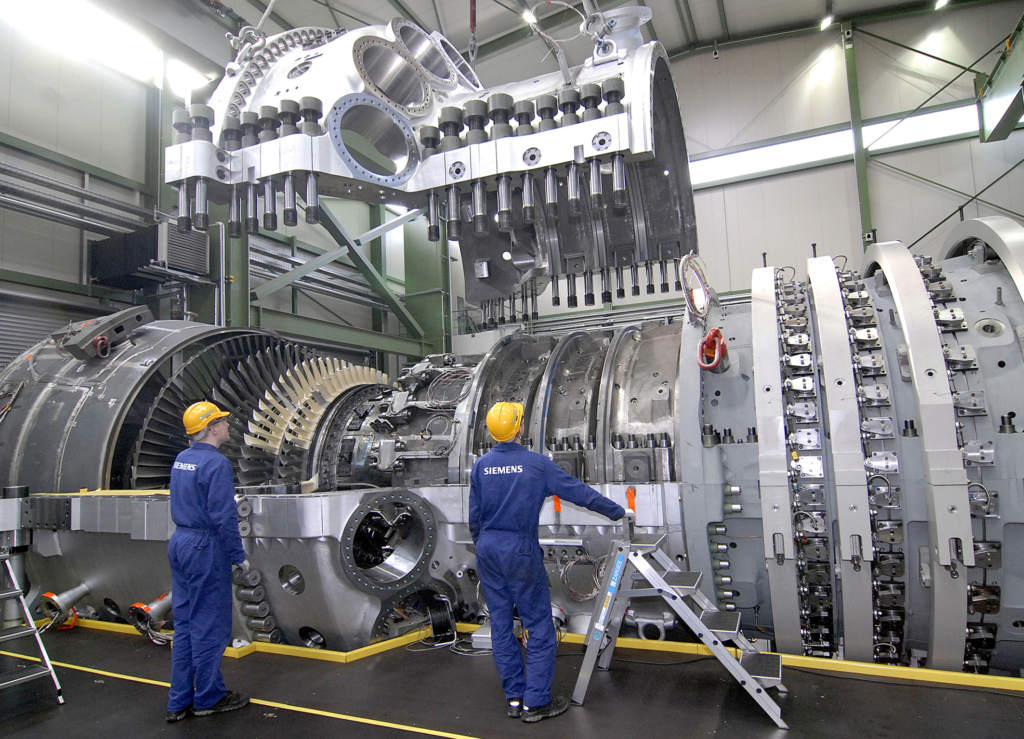

In TRADES these features will be enhanced to cater to objects with billions of geometric attributes, such as jet engines, gas turbines, electric motors, and generators.

Saigopal Nelaturi, PARC researcher and TRADES project lead explains, “Our work will enhance the ability to create, optimize, and fabricate these extremely complex designs by providing engineers access to tools that define the designs in terms of simple programs.”

Nelaturi adds the simple programs will automatically optimize design parameters for an object, and determine the best settings for fabrication.

A “one-of-a-kind combination”

Speaking on the collaboration as a whole Dr. Suraj Musuvathy, Senior Scientist at Siemens Corporate Technology, explains the advantages of the DARPA collective, saying, “Our team provides a one-of-a-kind combination of skills.”

Expertise at Siemens and Georgia Tech lies in an understanding of user experience of CAD systems. In addition, Siemens provides a wealth of additive manufacturing and material knowledge, as used to make the award winning 3D printed turbine blades.

Dr. Musuvathy continues, explaining that Michigan State has “a strong background in multidisciplinary optimization,” and that PARC, a research and development branch of Xerox, will provide access to “material scientists with extensive experience in commercial applications.”

The TRADES project is an expansion of DARPA’s existing FIELDS (Fabricating with Interoperable Engineering, pLanning, Design, and analysiS) project announced by PARC earlier in 2017.

Stay up-to-date with the latest 3D printing news by subscribing to our newsletter and following us on twitter and Facebook.

Featured image: TRAansformative DESign concept illustration from DARPA.