The Defense Advanced Research Projects Agency (DARPA) has awarded additive manufacturing materials developer Elementum 3D a Direct to Phase II SBIR contract to develop a 3D printing process for the metal rhenium.

Rhenium is one of the rarest metals on Earth and belongs to a group called the refractory metals. It’s known for its high density and extreme heat resistance, offering the second highest melting point among all metal elements on the periodic table (second only to tungsten).

The metal’s high-performance blend of thermal and mechanical properties makes it highly sought after as a component material in the aerospace sector, where parts are often subjected to high stresses and extreme heat. DARPA believes that the ability to 3D print with rhenium will help in the development of longer-lasting rocket and missile propulsion systems.

Elementum 3D’s AM materials

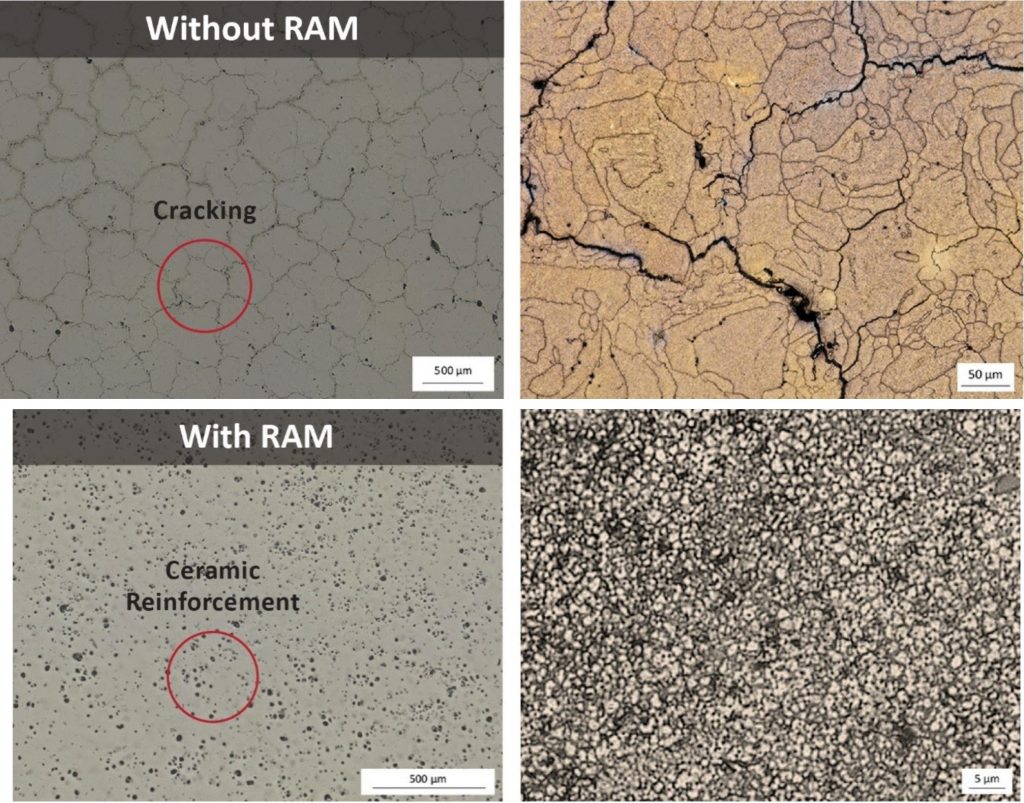

Based in Colorado and founded in 2014, Elementum 3D specializes in the research and development of advanced metal, composite, and ceramic powders for 3D printing. The firm creates its materials using its patented Reactive Additive Manufacturing (RAM) technology, which uses ceramic reinforcements to prevent the materials from cracking during the solidification process.

As such, it can be used to develop powders made of metals that typically aren’t compatible with 3D printing. This includes established wrought alloys such as aluminum 1000, 2024, 6061, 7050, and 7075.

In addition to its materials portfolio, Elementum also develops parameter sets for laser powder bed fusion. The company has already created repeatable processes for other refractory metals such as tantalum, tungsten, tungsten heavy alloy, and tungsten-rhenium alloy. DARPA expects this experience to come in handy when establishing a rhenium print process for critical applications.

Difficulties in processing rhenium

Rhenium is already widely used as an alloying constituent in nickel-based superalloys, but its usefulness as a base alloy is limited due to how difficult it is to traditionally process. For example, forming rhenium into complex geometries is costly because of its high melting temperature, and it’s also very difficult to machine as it undergoes extensive work hardening.

With a 3D printing process specifically for the metal, industrial 3D printer users would be able to bypass these restrictions and manufacture complex components with rhenium as the base material. Additionally, the use of additive manufacturing would enable geometric features that would be tricky to fabricate using conventional processes such as powder metallurgy and electrical discharge machining.

Ultimately, the DARPA project aims to cement rhenium as a viable additive manufacturing metal, allowing the material to be utilized for a variety of high-temperature propulsion and hypersonics applications.

If Elementum is successful in developing a rhenium printing process, an additional “option period” contract may also be executed by DARPA. This contract would involve the 3D printing and testing of end-use aerospace components in a bid to promote the commercial adoption of rhenium in the additive manufacturing sector.

Although 3D printed rhenium isn’t yet widely used in aerospace, metal additive manufacturing as a whole certainly is. Just last month, launch vehicle manufacturer Launcher successfully completed its latest set of hot-fire tests for its 3D printed E-2 liquid rocket engine at NASA Stennis Space Center. For the very first time, the firm’s rocket engine achieved nominal thrust, pressure, and oxidizer/fuel mixture ration, all while reportedly being in “perfect condition” after 40 seconds of test firing.

Elsewhere, propulsion system manufacturer Aerojet Rocketdyne recently received its largest RL10 contract to date from space launch firm United Launch Alliance (ULA). As part of the deal, Aerojet Rocketdyne will deliver 116 of its partially-3D printed RL10C-X engines to ULA for use in the latter’s new heavy-lift Vulcan Centaur rockets. ULA will use its new 3D printed engines to support the launch of e-commerce giant Amazon’s upcoming Kuiper satellite constellation.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows samples of rhenium. Photo via Alchemist-hp.