Cubicure, the Vienna-based startup behind Hot Lithography technology, has developed what is said to be the first flame-retardant material for SLA 3D printing.

Known as Evolution FR, the material is a halogen-free photopolymer that achieved a V0-classification in the UL 94 plastics flammability standard. Previously reserved for materials used in material extrusion or powder bed fusion processes, Cubicure states that Evolution FR is the only SLA material worldwide to achieve the qualification.

The combination of the company’s Hot Lithography material processing with a flame-retardant material opens up new applications for SLA 3D printing in the mobility sector and electronics market.

Cubicure Hot Lithography 3D printing explained

Founded in 2015 as a spin-off of TU Wien (Vienna University of Technology), Cubicure initially discovered its patented Hot Lithography 3D printing technology while attempting to expand the material choices available to common SLA 3D printing.

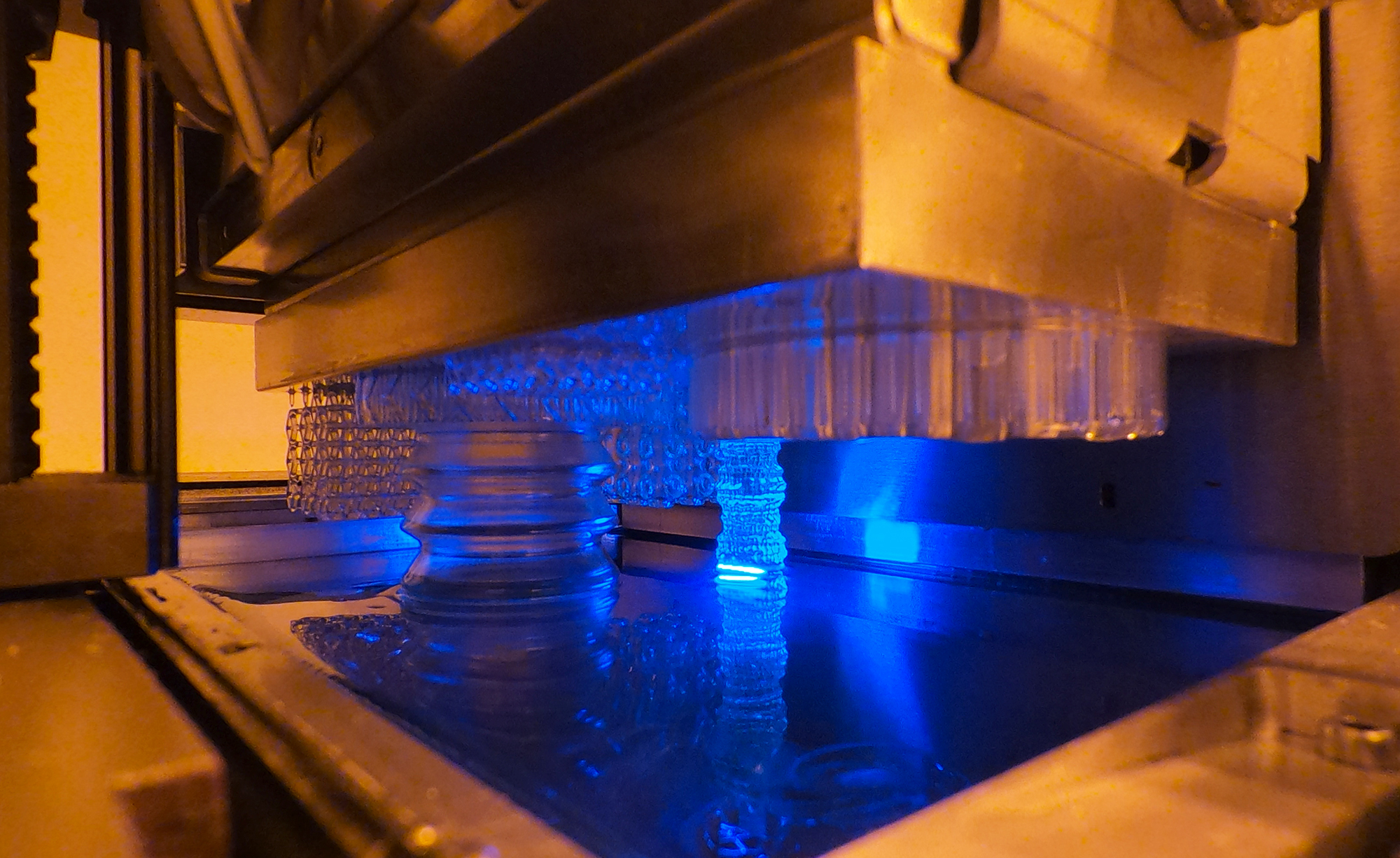

By increasing the operating temperature of its lithography systems, the team found they could facilitate the use of high viscosity polymers, thereby enhancing the material properties of the thinner materials used in SLA. The Hot Lithography method relies on a heated plate carrying thin layers of material into the processing area, which is then selectively cured by a precision laser-scanning-system.

By ensuring a constant temperature, Cubicure is able to overcome many of the challenges of working with viscous materials. This means that materials with higher impact strength, toughness and heat deflection than those typically used in standard “cold” SLA processes can be used with Cubicure’s Hot Lithography technology. The results are SLA 3D printed high definition plastic objects that exceed the properties of objects made with many common light-reactive materials.

Cubicure’s patented technology has helped it win a ‘Research-Oscar’ at the Research & Development in SMEs’ category at the ‘Houskapreis‘ 2019 research funding award in Austria, where the company placed 2nd. Furthermore, Cubicure recently announced a cooperative agreement with German specialty chemicals company Evonik to help develop more materials for the Hot Lithography process.

New applications for SLA in the electronics market

Cubicure’s new Evolution FR material can be used to 3D print complex flame-retardant objects with the Hot Lithography process and the precise capabilities of SLA 3D printing.

This enables new application fields for SLA additive manufacturing in industries like electronics, where flame-retardancy is an important requirement for polymers to meet certain standards and classifications guaranteeing proper safety for end users.

Having achieved the V0-classification in the UL94 protocol, which evaluates the flammability of polymers, the Evolution FR material can thus be used to manufacture key electronics components like plugs, connectors and clamps. The UL94 standard specifically tests the burning time as well as the dripping of burning parts or formation of burning drops in a material. A V0 rating certifies that the material is able to stop burning within 10 seconds on a vertically held sample, with no inflamed drops.

Cubicure will be premiering the Evolution FR material at Formnext 2019. You can visit the company at the show in hall 11.1, booth D.48, from November 19-22, 2019.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows electronics components 3D printed with Cubicure’s Evolution FR material. Photo via Cubicure.