3D printing is to play an important role in the next generation of shipbuilding. A portion of Denmark’s Green Ship of the Future (GSF) project will rely on the help of 3D printers to transform the supply chain and one day create emission free boats.

Joining a host of the maritime industry’s keys players on this project is 3D printing technology expert Create it REAL – the company credited with creation of one of the first file encryption systems for 3D printers.

Maritime is ready

As a pilot project, the GSF plans to install 3D printers on vessels and sites to help reduce the cost of spare parts and repair. The GSF project already has the crucial support of spare part supply chain partners J. Lauritzen, Maersk Line, Maersk Tankers and Maersk Drilling. MAN Diesel & Turbo, the world’s leading provider of large-bore diesel engines that has a standard 3D printing process for its gas turbine engines, has also joined the project. And DNV GL will be providing risk assessment and certification support, as it is in a similar project in Singapore.

Sverre Patursson Vange, Head of Performance Management at GSF partner J. Lauritzen, comments,

“3D printing technology is developing rapidly and we believe it is ready for utilization in the maritime industry,”

“However, the harsh environment and the top priority to safety calls for precautions why we are very pleased to have DNV GL, MAN Diesel & Turbo and Create it REAL participating in the project to address these issues.”

Taking inspiration from Spotify and Apple Music

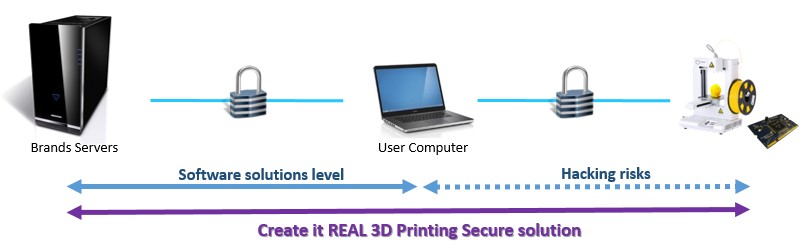

Create it REAL’s role within this directive is to ensure that digital integration aboard ships and offshore rigs is protected from the start. Create it REAL CEO Jeremie Pierre Gay explains, “We believe many companies are facing the same problem: how to share my files with my partners or customers while being sure to keep my intellectual property safe,”

Gay explains that they plan to use a 3D file sharing platform that works in a similar way to digital music players like Apple Music and Spotify, “You do not access the mp3s but you can still listen to the music depending on your subscription. We aim to create the same positive environment where end-users will have access to high quality branded content and IP owners keep what they worked for.”

Taking shape

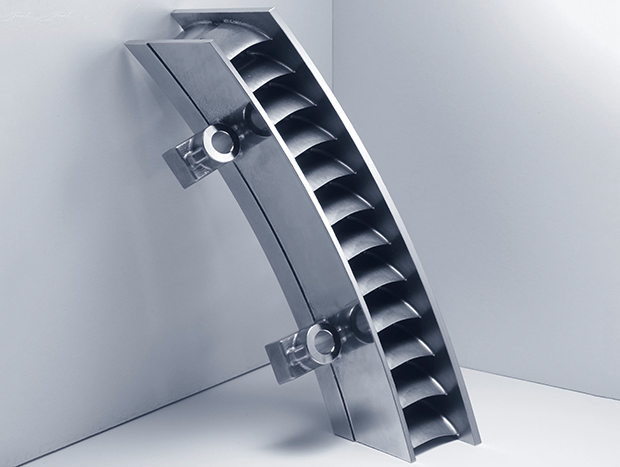

In the maritime world, Damen Shiyards has been making sufficient headway with its metal 3D printed WAAMpeller. Geert Schouten of the National Institute for Shipping and Shipbuilding (NISS) also made predictions that “The first digital ship builders will conquer the maritime world quicker than people think.”

The GSF project is funded by the Danish Maritime Fund, and coordinated by the Technical University of Denmark.

To stay up to date with this story and more subscribe to the 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Featured image shows a glowing 3D printed Benchy boat – the benchmark test for FDM 3D printers. Photo via Matterhackers