Insiders and analysts have made their predictions on the 3D printing trends to watch out for. Find out more in our series focused on the future of 3D printing.

Researchers at the University of Zaragoza, University of California, San Diego, and data consultancy firm GeoSpatium Lab have developed an affordable new ‘e-collar’ that could drastically reduce the cost of tracking livestock.

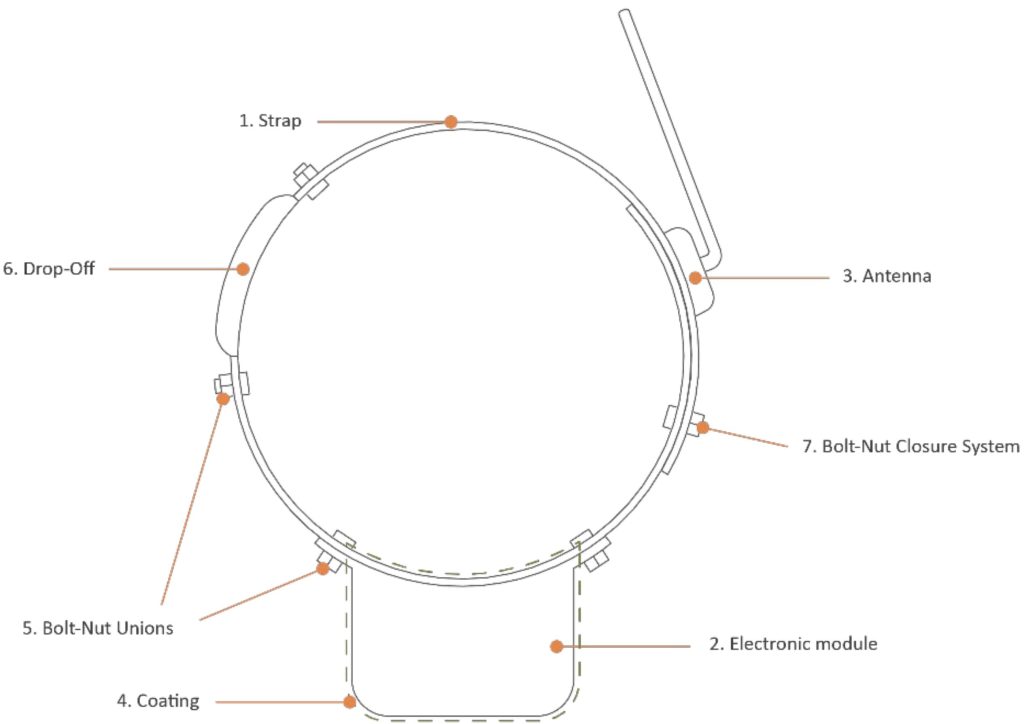

Using 3D printing, the engineers have managed to create a set of interconnected modules that house the antenna electronics required to relay telemetry, and attach them to a wearable monitoring band. Compared to traditional collars, the team’s design has proven to be three times lighter, half as thick, and much cheaper to produce, as well as being customizable to the needs of individual animals.

“We present a modular collar that distributes electronic components in several compartments, connected, and powered by batteries that are wirelessly recharged,” explain the researchers in their paper. “Its manufacture is based on 3D printing, something that facilitates immediacy in adaptation and economic affordability.”

“This device substantially improves the current offer[ing] of telemetry devices for farming animals, thanks to an animal-centered design process.”

Modernizing live animal tracking

Following decades of agricultural industrialization, a large number of farmers have now turned to telemetry-gathering technologies, with the aim of precisely tracking their animals’ daily movements. While this started with relatively rudimentary radio telemetry devices in the 1960s, animal rearers have since gradually begun to adopt modern GPS systems as well, due to their enhanced data-capturing capabilities.

In particular, the integration of mobile technologies like accelerometers, pressure sensors, and cameras into these GPS collars has shown great potential as a way of tracking the migration, foraging behavior, and habitat selection of larger mammals.

However, according to the researchers, the uneven weight distribution, cost of manufacture, and inflexible design of many such monitoring devices, makes them difficult to apply within livestock farming. To get around these drawbacks, the team say they have come up with a customizable new 3D printable alternative, that could lead to advances in “evolutionary, behavioral and veterinary research.”

Introducing the modular ‘e-collar’

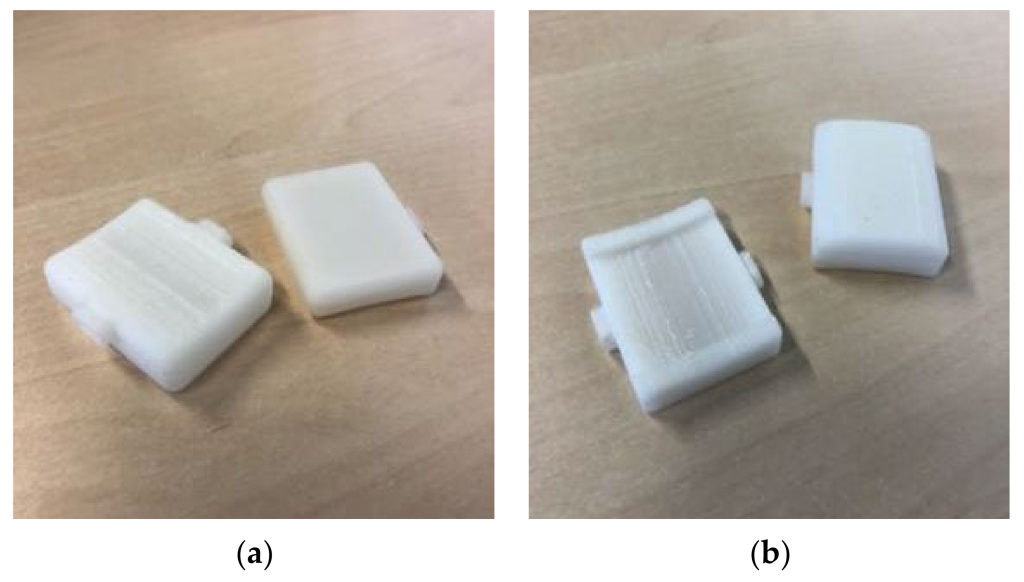

Nicknamed the ‘e-collar,’ the engineers’ farm animal tracking device consists of a series of electronic-packed compartments, powered by rechargeable batteries and attached to a leather strap. Each of these 3D printed modules features an ABS lid and body, with the inside of the latter designed with a degree of curvature, that can be customized to adapt to the circumference of a given animal’s neck.

When it came to the types of electronics housed in their 20 x 30mm modules, the team decided that two different specification collars would be needed: one for the intense tracking of small livestock and one for larger mammals, but both would require the same microcontroller, sensors, GNSS module and batteries to function.

Putting these designs into practise, the researchers eventually built two separate prototypes composed of seven modules, with four of each containing batteries. Interestingly, both also featured ‘drop-off’ security systems, designed to break the collar should animals become trapped, as well as varying locking mechanisms, with one using a single pin magnetic system, and the other being double-pinned.

In order to assess the efficacy of their devices, the research team opted to present them to a panel of veterinary experts, who found that their designs enabled the even distribution of weight across the strap, making them comfortable for animals to wear, and the double-pin version to be more effective as it prevented the collar from folding back on itself.

The engineers themselves, meanwhile, have concluded that their “design process puts the [animal] user at the center,” in a way that allows resulting devices to “collect accurate and reliable data without influencing carrier behaviors.” In future, the team say that the method behind their e-collar could therefore serve as a kickstarter for farming innovation, particularly given its improved affordability.

“The results of this research are of interest to designers and manufacturers of animal telemetry and technologists and professionals in the animal and farm sector since they contribute to the knowledge about animal monitoring through the design of the device itself, and the methodological approach used for its achievement,” the team concluded in their paper.

3D printing in the farming sector

They may not be the highest-profile of applications, but 3D printing has actually been used by farm hands around the world in recent years, to overcome various different agriculture and cultivation-related obstacles. Back in 2019, Norfolk farmer, Jonny Leech used 3D printing to build a maize seed metering system that effectively improved the consistency of his crop performance, his maize yields in particular.

More recently, engineering firm Scheurer Swiss GmbH has worked with students at ETH Zürich to help develop their ‘Rowesys’ robotic weeding system. Featuring several carbon-reinforced performance-enhancing components, the compact weed-killing bot is designed to serve as an eco-friendly alternative to the use of herbicides in agricultural farming.

At the UK’s Loughborough University, meanwhile, researchers have come up with a way of turning polymeric waste into low-cost agricultural tools. Developed as part of their ‘Circular Plastics Project,’ the team’s set of contraptions, ranging from a fruit picker to a fish farming system, are built for deployment in developing countries, where they could help boost local economies and reduce their build-up of refuse.

The researchers’ findings are detailed in their paper titled “Modular E-Collar for Animal Telemetry: An Animal-Centered Design Proposal,” which was co-authored by Marta Siguín, Teresa Blanco, Federico Rossano, and Roberto Casas.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a schematic of the researchers’ telemetry collar. Image via Marta Siguín, Teresa Blanco, Federico Rossano and Roberto Casas.