A strong buzz in the 3D-printing community is emerging around 2BEIGH3, a printer-slash-CNC machine to be made at home, capable of using Nylon in addition to traditional ABS/PLA and others as raw material for 3D-printing.

2BEIGH3’s main advantage compared to more conventional, single-purpose CNC and 3D-printers is the combination of best of both worlds – the raw power of CNC and the speed and agility of 3D-printer.

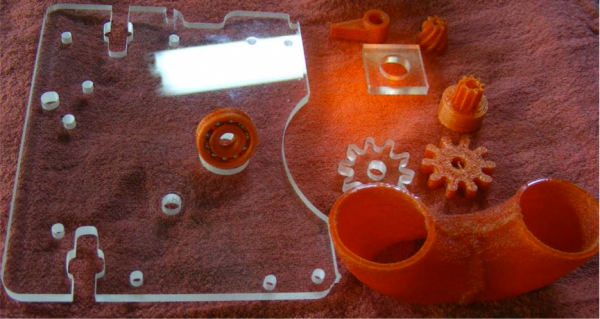

Using nylon and its polymers in the printing process has already led to some inspiring outcomes, such as bearings needing no external lubrication.

Have a look at these and some other recent results with this machine after the break.

Pushing the curtains of mystery surrounding the manufacturing of a such innovative machine aside, a complete how-to is fully layed out with clearly illustrated and animated instructions in the author’s (who is not so openly known as Taulman) Instructables site.

The machine is already been built, used and modified in all parts of the world – the Americas, Europe and Asia. The main challenge preventing an even wider adoption has been the availability of the Nylon itself.

In the most recent developments, however, the author and brains behind the 2BEIGH3 project has partnered with a manufacturing company called Shakespeare Monofilaments in order to make the most suitable kind of Nylon for 3D-printing available for all enthusiasts.

The project regarding the created ”3D-nylon” is at a test phase and eager testers are seeked. So be sure to check the author’s site out and if you are already part of the 2BEIGH3 community, sign up and also post the results of your nylony tests!