Researchers at Columbia University, New York has shown a method to replicate the external and internal structure of wood using a 3D printer.

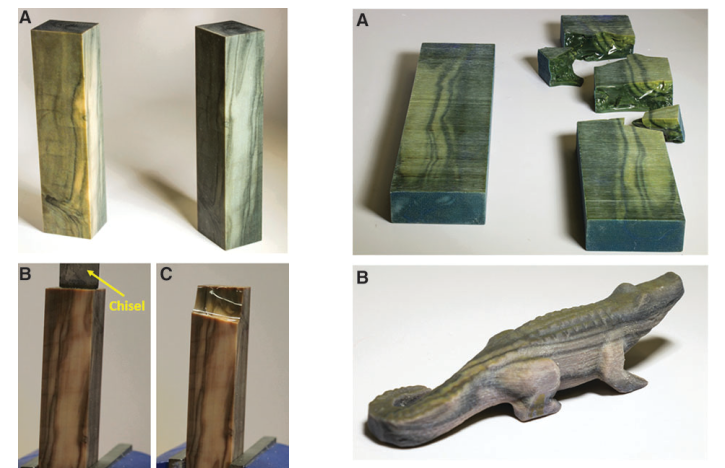

With the help of imaging and color and voxel mapping techniques, engineers were able to mimic the unique texture of olive wood.

Seeing inside wood

Recently, an MIT study showed how a 3D printer with the help of AI can reproduce classic works of art. But, in the MIT study, the problem was copying the colors, and merely the outer form of the painting.

Whereas, one of the primary challenges, in the recent study, titled, Digital Wood: 3D Internal Color Texture Mapping, was replicating the internal texture of a wood block. This meant not only seeing underneath the surface of the wood but also replicating it using a 3D printer.

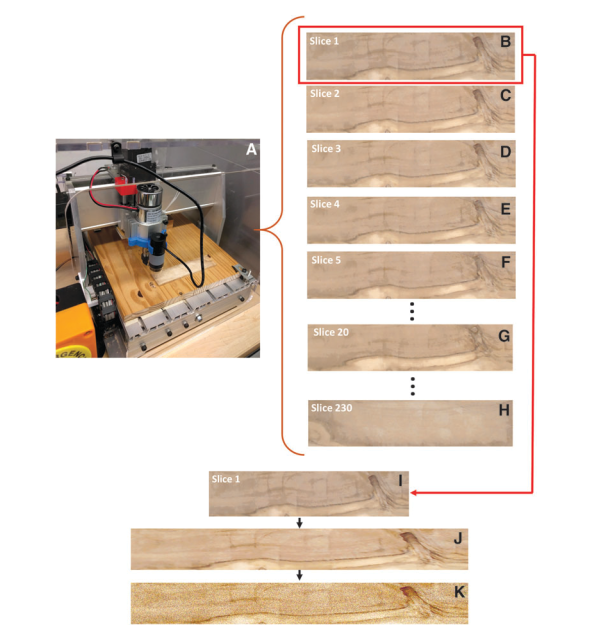

The difficulty of exposing and scanning the internal structure was overcome by using a destructive imaging technique, or destructive tomographic imaging (as it is called in the paper).

Destructive imaging involved slicing the wood with a 3040T desktop CNC machine, with a camera controlled by a Python program taking consecutive images. Each slice cut away by the CNC machine was 27 microns in height corresponding to the layer height of the 3D printer used in the study, a Stratasys J750 PolyJet machine.

The CNC machine ran through the wooden surface two hundred and thirty times, and each time the attached camera captured an image of the wood.

3D printing wood texture

The images collected in the previous stage were processed step by step to make them into a 3D printable code compatible with the Stratasys J750 Polyjet printer (capable of printing various materials and colors.).

Firstly, the images were scaled to match the 3D printer’s xy resolution of 600 x 300 pixels per inch. Then, the RGB images captured with the help of the CNC machine and a camera were translated into CMYK color standard, as this is the one used by the inks used in Stratasys J750 printer. Finally, a GrabCAD voxel file (GCVF) was generated and printed.

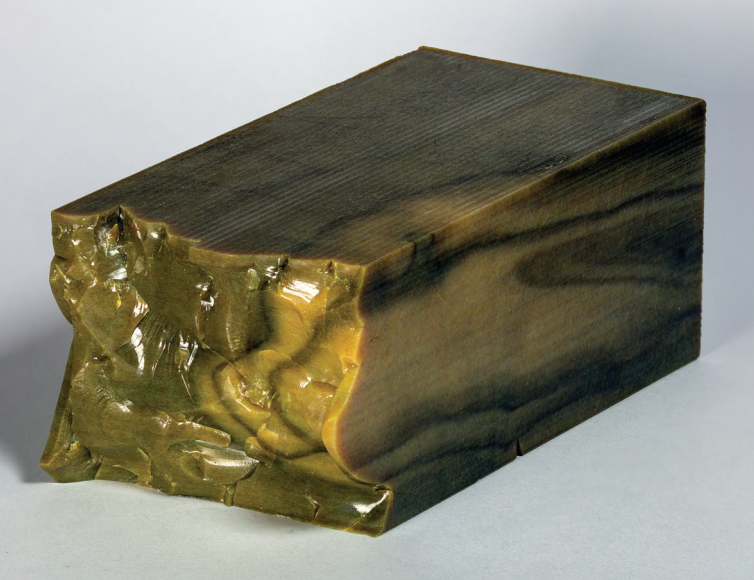

The study concludes, “Other texture properties such as specularity are limited by the mixing mechanics of photoacrylates and the printer resolution, respectively. Nevertheless, the ability to replicate internal grains in color profiles can be extended to replicating stiffness profiles for materials whose physical properties map closely to their visual properties. The ability to take the internal profile of one material and apply it to another has significant implications for both designers and manufacturers.”

The research discussed in this article was titled, Digital Wood: 3D Internal Color Texture Mapping published by Mary Ann Liebert, Inc. It was jointly authored by Fabian Stute, Joni Mici, Lewis Chamberlain, and Hod Lipson.

Nominations for 3D Printing Award 2019 are open. Please let us know about the leaders in the 3D printing industry.

To know more about the latest research happening in additive manufacturing, subscribe to our 3D printing newsletter. You can also visit us on Facebook and Twitter.

Our 3D Printing Jobs site has a lot of careers.

Featured image shows an example of a replicated wood using the Stratasys J750. Image via Mary Ann Liebert, Inc., publishers.