Hoping to overcome the limitations of current 3D food printers (3DFPs), scientists from Columbia University have developed a new method to 3D print cooked food. This latest method is unique insofar as it can combine different ingredients—such as chicken with dough—and cook each ingredient selectively.

Most importantly too, the products are edible. And, according to the researchers, “The high resolution of our IR spot allows for the combination of food ingredients at a much closer level, giving rise to new flavor profiles and inventive food recipes that would be more challenging to achieve using conventional cooking methods.”

A novel way to 3D print cooked food

Publishing their findings in 3D Printing and Additive Manufacturing, the Columbia team state that “Current 3DFPs are limited with their ability to combine ingredients due to the lack of high-resolution heating; they are limited to using microwaves, ovens, and other common heating appliances to process extruded food.”

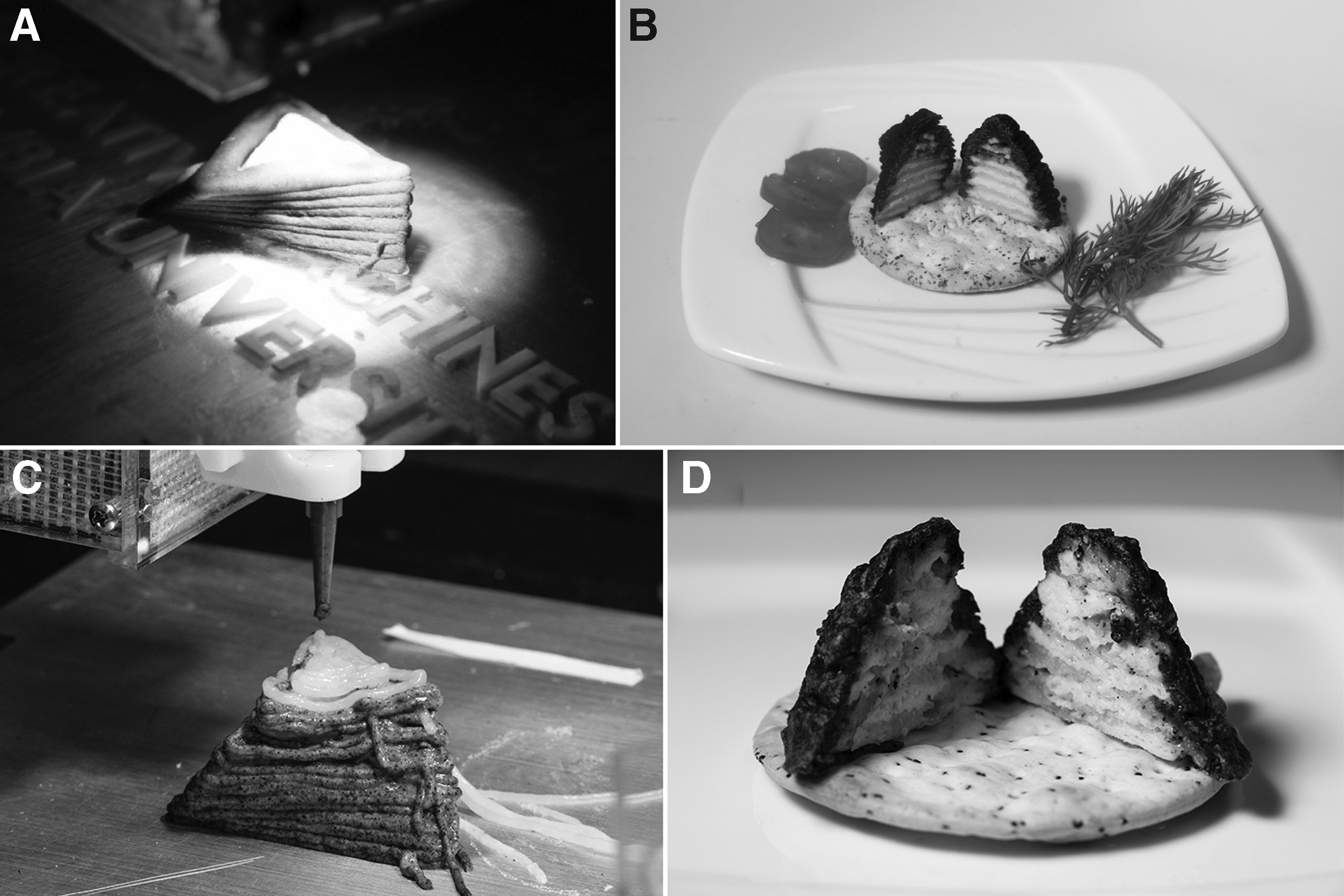

To overcome the limitations of cooking multiple different ingredients at the same time in a 3D printer, the Columbia team retrofitted an existing CNC machine (a modified X-Carve) with an extrusion and heating mechanism – a infrared (IR) lamp. The use of IR technology allowed the food to be cooked without physical contact with the lamp, making it ideal for so-called “food layered manufacture” (FLM).

“Integrating an infrared lamp heating mechanism into the printer allows for more precise spatial control of the heat being delivered to printed food, the ability to create complex food patterns with more ingredient complexity, and the integration of multiple food ingredients in a single 3D object,” claims the paper.

An evolution in 3D printed food

In recent years many companies have made inroads into the 3D printed food market.

Founded in 2016 FoodInk, for example, is a restaurant where all the food is 3D printed. However all the food 3D printed there requires no cooking. Beehex, a company from Columbus, Ohia, produces pizza 3D printers, which have three separate nozzles for each ingredient, and an oven able to produce a hot pizza in 4 minutes. Even NASA is exploring 3D food printing for meal creation on space stations, and 3D Systems markets the sugary ChefJet Pro 3D printer.

What separates Columbia’s iteration of a 3DFP is the ability to print with six different materials derived from traditional foods: sweet dough, jujube jam, sesame paste, shrimp paste, chicken paste, and choux dough. The team have claimed that this latest feat will allow chefs and designers of the future to “re-imagine the way food is assembled and prepared in the modern kitchen,” bringing us one step closer to customizable 3D printed cooked food.

Hod Lipson, a co-author of the recent Columbia University paper, has also been invested in the advancement of 3D printed food for several years.

A full exploration of this new method, titled “Multi-Material Three-Dimensional Food Printing with Simultaneous Infrared Cooking” is published online in 3D Printing and Additive Manufacturing journal. It is co-authored by Evan Hertafeld, Connie Zhang, Zeyuan Jin, Abigail Jakub, Katherine Russell, Yadir Lakehal, Kristina Andreyeva, Sneha Nagaraj Bangalore, Jerson Mezquita, Jonathan Blutinger, and Hod Lipson.

Submit your trophy design and cast your vote for the 2019 3D Printing Industry Awards now.

For the latest additive manufacturing news, subscribe to our 3D printing newsletterand follow us Facebook and Twitter. Visit our 3D Printing Jobs board to find out more about opportunities in additive manufacturing.

Featured image shows a completed example of food 3D printed using the IR method. Image via 3D Printing and Additive Manufacturing.