Ahead of their physical unveiling at Euromold this week 3D Systems has revealed two of its new 3D printing developments — the ProJet® 4500 3D printer and the ProJet® 5500X.

Further information from the company on this 3D printer includes the fact that it “delivers strong semi-rigid parts, pixel-by-pixel, straight out of the printer, in high-resolution, pantone-like colour with a superior surface finish. Safe for office, easy-to-use, sustainable to operate and fast to print on, the ProJet 4500 is economical and comes with fully integrated material recycling for greater yield and better total material usage.”

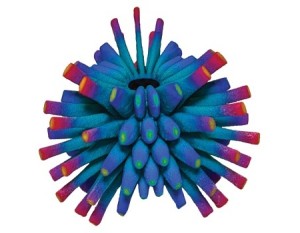

I’m heading to Frankfurt really REALLY early tomorrow morning, so I’ll get up close to this one and I will ask about the “pixel by pixel” claim, as well as asking exactly what “pantone-like” means. You’d also need a pretty big office to accommodate this size of 3D printer! That said, the black box aesthetic of the system does fit in with the now extensive ProJet range, which is a nice contrast with the models it is capable of producing:

The second high end 3D printer announced by 3D Systems is also in the ProJetrange — and again, the focus is on the materials. The ProJet 5500X is denoted as “a ground-breaking engineered composite materials 3D printer that delivers the highest quality, most accurate and toughest multi-material composites based on its latest MultiJet Printing (MJP) technology.” This is competing directly with Stratasys’ Objet Connex platforms. With another pixel reference, 3D Systems says: “The ProJet 5500X simultaneously prints and fuses together flexible and rigid material composites, layer-by-layer at the pixel level, in a variety of colours and shades including opaque, clear, black or white and numerous shades of gray.”

I will be looking to verify exactly how this compares with the Connex 1000, which has a build volume with 1m in the x-axis. The 3D Systems vs Stratasys battle seems to be hotting up in the 3D printing sector, so it’s important not to get lost in the marketing side-swipes at each other. The latest of which seems to be: “3DS invented MJP printers and was the first to commercialize it in 1996. Today its MJP printers are the company’s best-selling category for the most demanding design-to-manufacturing applications for aerospace, automotive, jewellery, patient-specific medical device and a variety of mechatronic and investment casting companies worldwide.”

Regardless of the war of the 3D printing giants, these two new 3D printers from 3D Systems, are reportedly two of a dozen new products” to be introduced at Euromold this week.

Stay tuned, I’m heading to the show floor imminently ….