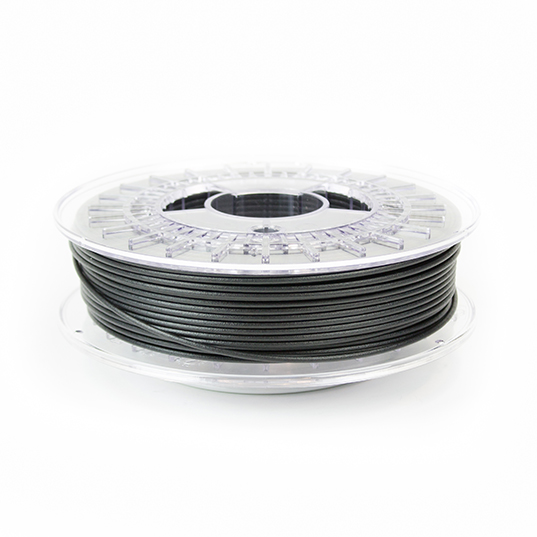

colorFabb, the Netherlands-based 3D printing materials company, is releasing a new carbon fibre-infused polyamide 3D printing filament with “high-strength” and “low-warp” qualities, developed together with German materials R&D company LEHVOSS Group.

The new product, “PA-CF Low Warp,” has the mechanical properties of PA6, but also boasts enhanced printability and moisture control.

Four times more resistant to moisture

The PA-CF Low Warp material works with any FDM/FFF 3D printer which has a hot-end temperature of between 260ºC and 280ºC and can be fitted with an abrasion-resistant nozzle (owing to the abrasive nature of Carbon fiber).

Along with high tensile and impact strength, the PA-CF Low Warp can also be used continuously at 120°C while “sufficient properties for the intended application are retained.”

The modified chemical formulation of the filament reduces the uptake of moisture compared to PA6. The saturation point, where a build-up of moisture in the filament affects the print, takes almost four times longer to reach compared to PA6.

Reduced warping on an ambient temperature print bed

The formulation of PA-CF Low Warp filament allows printing on non-heated build platforms with low warping. For low infill designs, the prints come out flat on a cold bed. Higher infill designs can be 3D printed with a 40-50ºC build plate temperature and come out flat.

“In most cases, engineering materials can be very challenging to print,” explained Ruud Rouleaux, director at colorFabb B.V, which recently moved headquarters to Belfield earlier this year, “but what we’ve seen from our tests on several popular 3D printers is that the PA-CF Low Warp has excellent properties and can even be printed without warping on a build plate at ambient temperature.”

“Our materials enable 3D printing to be used not only for the traditional prototyping applications but also for functional parts and series production,” added LEHVOSS 3D printing Market Development lead Thiago Medeiros Araujo. “Having an improved layer adhesion and reduced warping, coupled with the high-quality filament technology of colorFabb, makes the whole process reliable and repeatable.”

The PA-CF Low Warp 3D printing filament is colourFabb’s first material since the release of the nGen_LUX filament in September. The new colorFabb filaments are currently available for pre-order ahead of shipping this week.

Nominations for the second annual 3D Printing Industry Awards are now open. Make your selections now.

For more information on 3D materials, subscribe to our free 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Featured image shows the assembly of a fully-3D-printed modular RC Sailplane made with PA-CF Photo via colorFabb.