New research carried out by the French Space Agency (CNES) is investigating how 3D printed oxide ceramic materials could improve the design of crucial subsystems for space propulsion.

The research focuses on the development of an optimized yttrium aluminum garnet (YAG) xerogel that offers desirable strength and creep-resistant properties when 3D printed into complex shapes.

According to CNES, these additively manufactured YAG ceramics could form the basis of metal alloys used in future turbine blades for deep space exploration.

Ceramic 3D printing for space

3D printed ceramics are being increasingly explored for a range of space-related applications, due to the materials’ desirable mechanical properties and the geometric design possibilities enabled by additive manufacturing technologies.

For some years now, 3D printed ceramics have been leveraged for the creation of enhanced components within next-generation rocket engines, alongside other novel aerospace applications. One company at the forefront of ceramics innovation is CeramTec, which has previously worked with the European Space Agency (ESA) and Airbus to produce a new generation of ceramic sample containers for a space experiment facility aboard the International Space Station (ISS).

The ISS is also home to Made In Space’s ceramic manufacturing facility, the Turbine Ceramic Manufacturing Module (CMM), which contains an SLA 3D printer to demonstrate the feasibility of manufacturing single-piece ceramic turbine components in microgravity environments.

More recently, Digital Composite Manufacturing (DCM) 3D printing platform developer Fortify has teamed up with ceramic 3D printing specialist Tethon 3D to develop new technical ceramics for additive manufacturing, including extreme temperature parts like rocket nozzles.

Elsewhere, 3D printing service bureau 3DCeram has partnered with CNES spin-out Anywaves to design 3D printed ceramic antennas for small satellites, while Austrian engineering firm Incus is currently working with the ESA and ceramic 3D printing specialist Lithoz to explore how scrap metals available on the moon’s surface could be processed for 3D printing spare parts for lunar stations.

Improving space propulsion system design

CNES’ latest research and development efforts regarding oxide ceramics hope to improve the design of crucial subsystems for space propulsion in order to enhance the performance of liquid propulsion rocket engines.

Currently, the maximum allowable turbine temperature, imposed by the resistance of metallic alloys, is limiting the performance of liquid propulsion rocket engine cycles. According to the agency, the introduction of creep-resistant oxide ceramics for turbine parts could help to increase cycle temperature and therefore improve performance during deep space exploration missions.

YAG was chosen due to its desirable mechanical properties at high temperatures, in particular its high strength, good creep behavior at temperatures above 1000 degrees celsius, low thermal conductivity, physical and chemical stability, and its high resistance to water vapor corrosion.

Currently, due to its low cost and ease of use, extrusion is one of the most widely used technologies for the direct shaping of ceramics. While additive manufacturing has been used to print YAG ceramics in the past, the team identified potential challenges to scaling up the process and producing larger amounts, such as the formation of impurities.

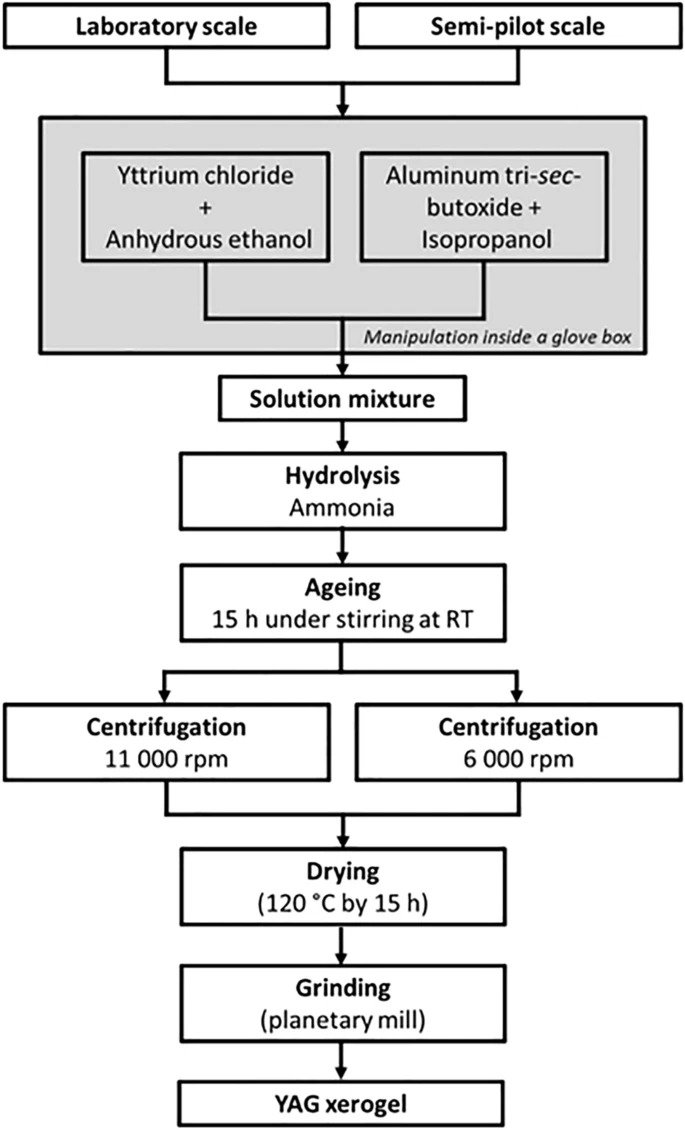

As a result, they embarked upon improving and scaling up the process for preparing a YAG xerogel – the solid left behind when the liquid from a gel is evaporated at room temperature – and investigating the printability of the resulting xerogel-based paste.

Lowering costs and saving energy

Using this technique, the CNES team successfully scaled up the production of the YAG xerogel by modifying a protocol designed for a ‘laboratory scale’ synthesis. The researchers used dried YAG xerogel to formulate a paste which could be 3D printed using a Delta WASP 2040 clay 3D printer from construction 3D printing firm WASP.

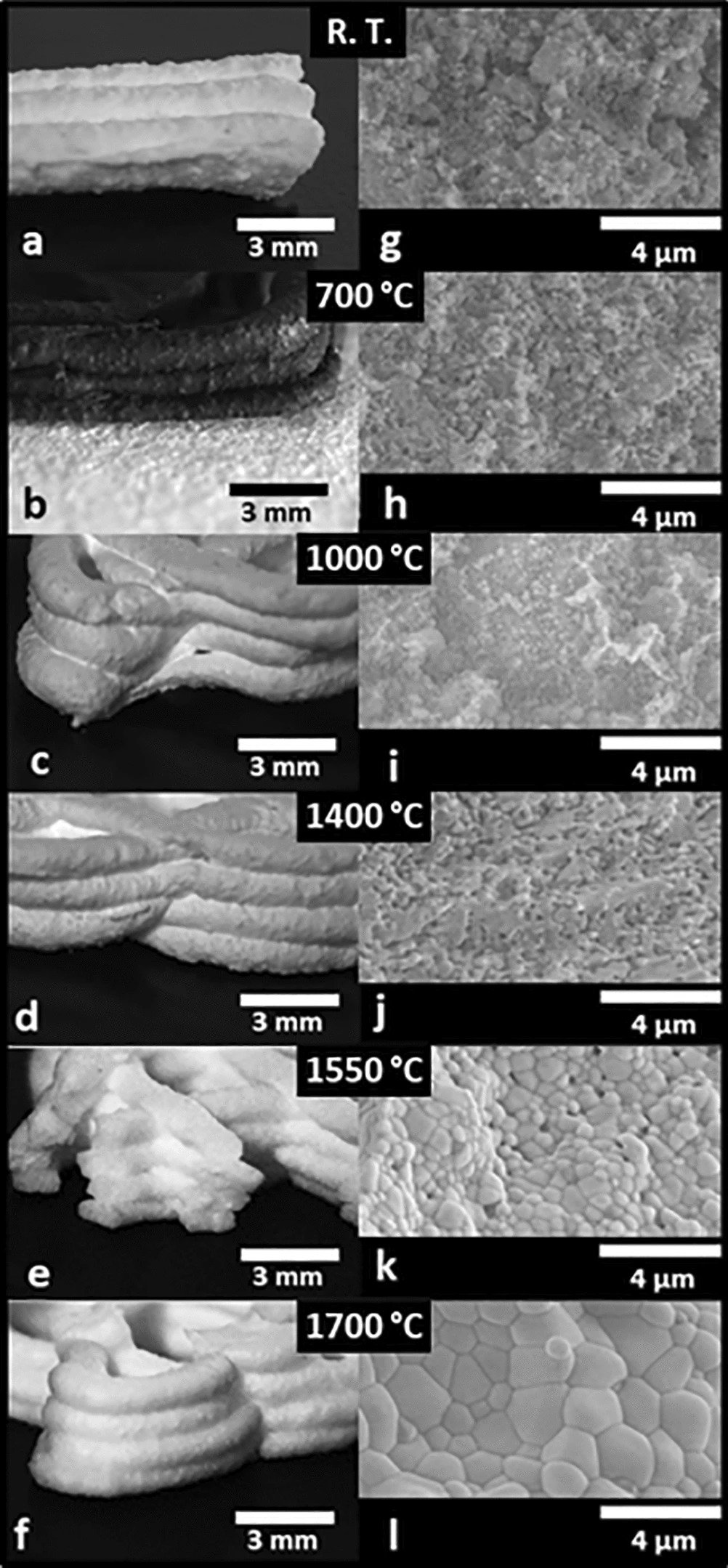

The printed cord structures were then calcined at different temperatures to monitor the transformation of the xerogel into a crystalline YAG ceramic. Through this process, the team proved the possibility of sintering and obtaining cohesive ceramic pieces after thermal treatments between 1550-1700 degrees celsius.

The team also observed that their combined preparation and 3D printing process was capable of reducing costs and energy, and would therefore be “appreciated by the industrial sector” as an energy saving process. In particular, the CNES team views the fabrication of ceramic turbine parts for space exploration as a promising application for their 3D printed YAG xerogels.

Further information on the study can be found in the paper titled: “Synthesis and robocasting of YAG xerogel: one-step conversion of ceramics,” published in the Scientific Reports journal. The study is co-authored by N. Flores-Martinez, L. Quamara, F. Remondiere, J. Jouin, G. Fiore, S. Oriol, and S. Rossignol.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews, and webinar replays.

Featured image shows the 3D printed YAG ceramic structures. Image via Scientific Reports.