Edwin and Liesbeth ter Velde, a Dutch couple from non-profit sustainable living organization Clean2Antarctica, are set to make a 2,400 km journey in a 3D printed no-waste, no emission solar-powered vehicle.

Driving from Antarctica to the South Pole, the expedition is to draw attention to the Convention on the Conservation of Antarctic Marine Living Resources (CCAMLR), a treaty to preserve Antarctica’s environment and its marine life.

The 30-day journey will begin on November 27, 2018.

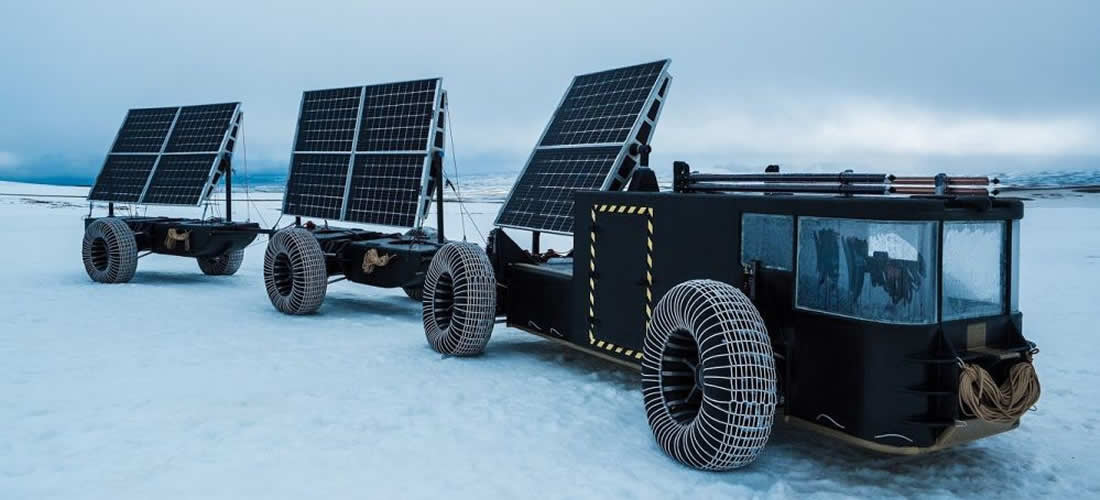

3D printed Solar Voyager

Edwin and Liesbeth ter Velde’s adventure began in 2015 when, instead of wasting the plastic in their trash, they decided to upcycle it. The couple melted the plastic to make 3D printer filament.

Graduating this idea to a larger scale, the couple obtained recycled pellets from a plastic waste plant, transformed them into filament, and then 3D printed 4000 hexagon pieces (HexCores). These HexCores were then incorporated into the body of their solar vehicle named the Solar Voyager.

The massive vehicle weighs 1485 kg, which limits its maximum speed to 8 km/h. The Solar Voyager is 16-meter-long and holds ten huge solar panels to provide the vehicle with energy. Two of its trailers carry food supplies that could last up to 47 days. To provide water, the vehicle is equipped with six vacuum solar tubes which melt the snow.

Including parts of its body Solar Voyager’s steering wheel, steering cable attachment, and steering house are made with 3D printing.

Throughout the expedition, the Solar Voyager will be accompanied by a support group, who will film the journey and provide emergency response.

Sponsoring the expedition to Antarctica

Since the beginning of the expedition, various companies from around the world have shown support for the Clean2Antarctica project.

Teijin Ltd, a Japanese chemicals company specializing in high-performance fibers and composites, announced that it will provide materials for the Solar Voyager.

The company’s proprietary Tenax carbon fiber is used to reinforce the 3D printed parts of the vehicle’s body. Teijin’s high-strength aramid fibers are used for towing the vehicle and angling the solar panels for the optimum light absorption.

The infrared windows of the Solar Voyager, for absorbing the sunlight, are glazed with Teijin’s Panlite polycarbonate (PC) resin. PC can withstand extreme temperatures ranging between -100-129℃.

A worldwide manufacturer of gearboxes, Apex Dynamics, has contributed four planetary gearboxes to the Solar Voyage. Planetary gearboxes provide the highest possible gear rotation power in the smallest of gear designs. The PD 090-050 gearboxes used in the Solar Voyager have torque power between 10 Nm – 232 Nm.

Dufor, a Netherland-based customize polyester specialist, is also among the sponsors of the Antarctica project.

To stay up-to-date on the Solar Voyager journey, subscribe to our 3D printing newsletter. Also, join us on Facebook and Twitter.

For jobs in the 3D printing industry, visit our 3D Printing Jobs.

Featured image shows the Solar Voyager. Image via Climate Change