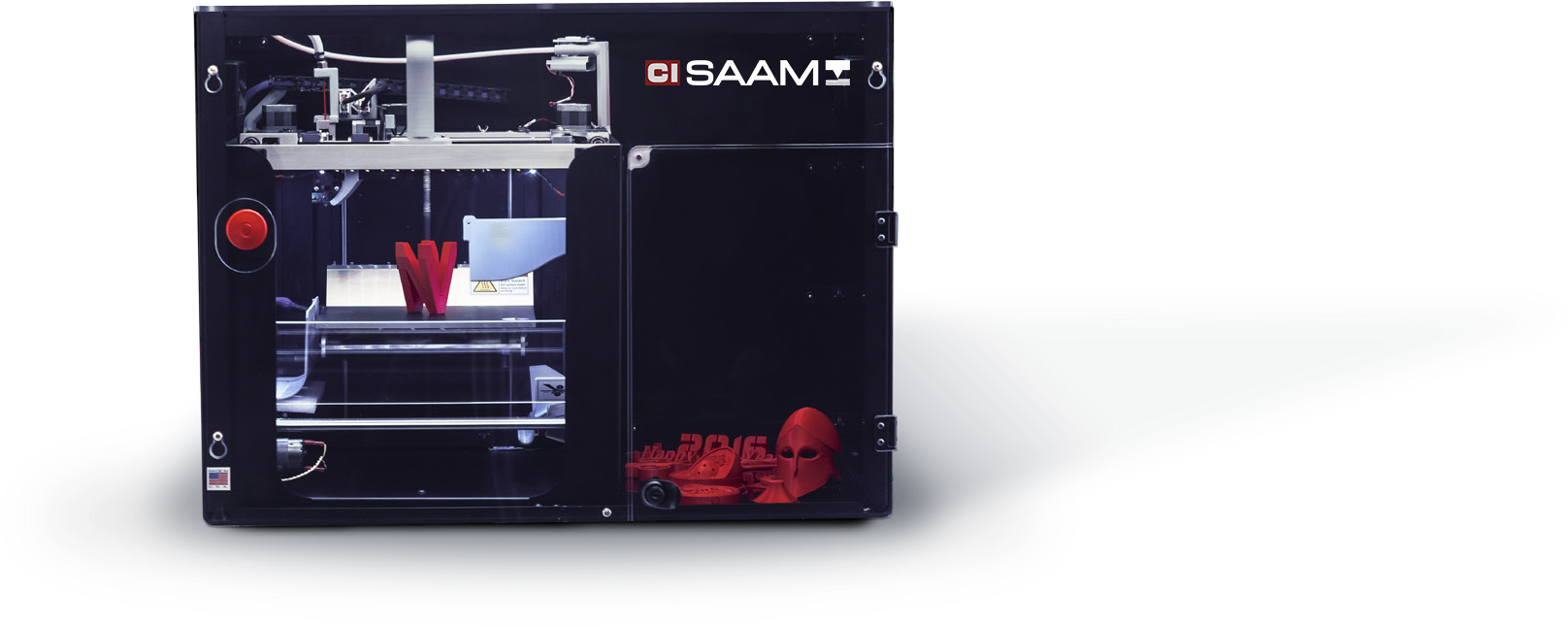

Ohio-based metal fabrication equipment manufacturer Cincinnati Incorporated has announced it will showcase its Small Area Additive Manufacturing (SAAM) system at EASTEC 2019 in West Springfield, Massachusetts. The SAAM system from Cincinnati Incorporated is a 3D printer utilizing FFF technology, designed to operate alongside the company’s Big Area Additive Manufacturing (BAAM) and Medium Area Additive Manufacturing (MAAM) systems.

EASTEC is a manufacturing trade show dedicated to advanced manufacturing technology in the Northeastern United States in a variety of industries, such as aerospace, medical devices, automotive, industrial equipment and defense.

Meet BAAM, MAAM and SAAM

Cincinnati Incorporated’s BAAM and MAAM systems are industrial sized machines created with the intention of bringing the advantages of 3D printing to production manufacturing. The systems are designed to provide cost-effective methods of producing large parts quickly with 3D printing, using an open architecture for material vendors.

The SAAM was developed by Cincinnati Incorporated specifically as a complement to the BAAM and MAAM machines. Whereas the BAAM and MAAM are focused on full-scale production, the SAAM is a smaller machine focused on prototyping parts and ideas before being used on the larger machines. A key feature of the SAAM system is its ability to carry out 3D prints continuously and unattended, using the company’s Automated Ejection System technology. Cincinnati Incorporated also offer an upgraded version of the SAAM, the SAAM HT, which provides the additional ability of 3D printing in ULTEM, PEEK, polycarbonate or other thermoplastics up to 500°C, allowing for the production of stronger parts.

You’ll be able to see the SAAM system from Cincinnati Incorporated in action at EASTEC 2019 from 14th May through to the 16th May 2019, in Booth #1844.

Large 3D printing with BAAM

Thanks to the large-scale 3D printing potential of the SAAM’s bigger counterpart, the BAAM from Cincinnati Incorporated, developed in partnership with Oak Ridge National Laboratory (ORNL), has been used for a variety of applications in order to create unique, large 3D printed parts.

Previously, the BAAM system was featured in the Guinness World Records in 2016 for producing the largest 3D printed part in the world. Local Motors, a ground mobility company, has used the capabilities of BAAM technology the 3D print an entire vehicle known as the Strati in 44 hours back in 2014. The system has also been utlized to 3D print the hull of a submarine for the U.S. Navy in 2017.

Recently however, BAAM has been employed to help run the 2019 Flying Pig Marathon, a charity event established by non-profit organization Cincinnati Marathon, Inc. The BAAM 3D printer was used to produce a “13.1” sign (representing half the 26.2 miles of the marathon) for the charity run, which Cincinnati Incorporated in sponsoring.

You can now cast your vote for the third annual 3D Printing Industry Awards. Help decide this year’s winners now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also keep connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the SAAM system from Cincinnati Incorporated. Image via Cincinnati Incorporated.