Researchers from Beijing have reported the use of 3D printing and injected liquid metal as a novel way to create functional electrical components.

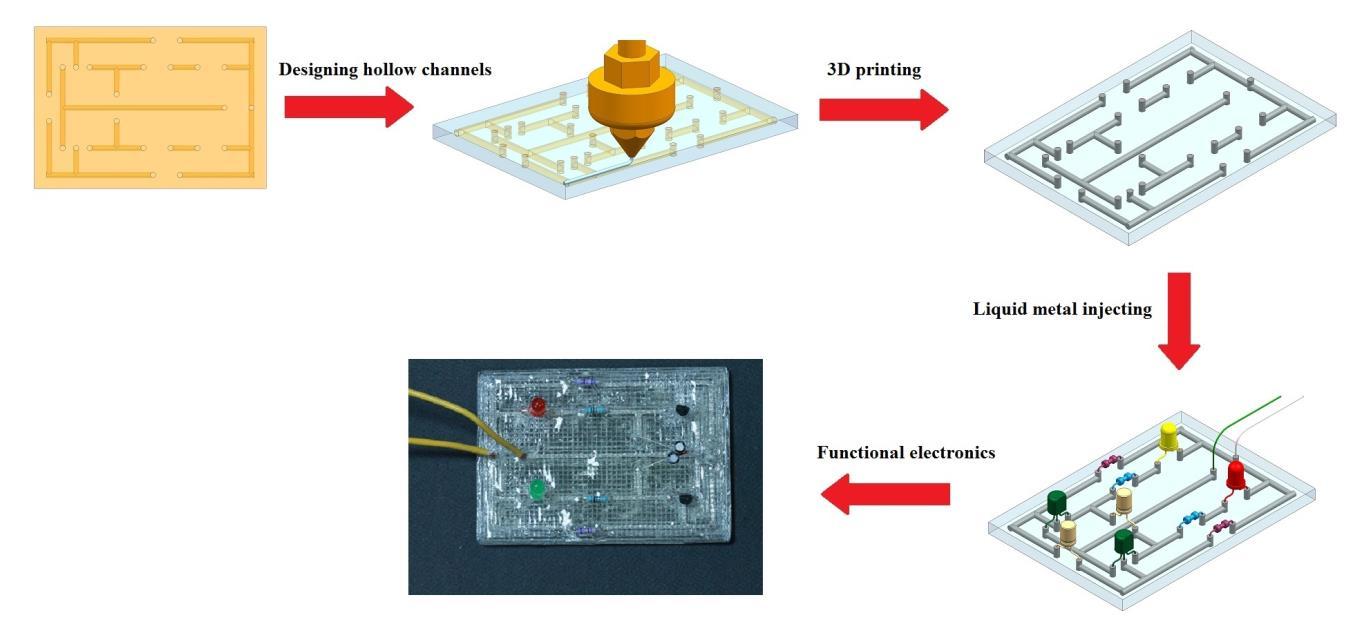

Citing the “fabrication freedom” that is enabled by 3D printing as a manufacturing technique, the academic paper explores the possibilities of embedding liquid metal in an 3D printed elastomer substrate. The authors explain the process as follows,

The technique involves printing hollow channels within elastomer structures via fused deposition modeling (FDM), then injecting and encapsulating liquid metal to form electrical traces.

3D printed electronics

While this particular research looks at injecting liquid metal, there are several groups currently exploring 3D printing electronic components. These processes enable the creation of PCB boards with a 3D printer and droplets of metals or conductive inks. One example is Nano Dimension and their Dragonfly 2020 3D printer. The Dragonfly 3D prints circuit boards using piezo inkjet deposition.

Elsewhere, 3D Printing Industry recently spoke to representatives from a Japanese group about their Super Inkjet Technology (SIJT). Super Inkjet Technology Inc. is exploring the method of 3D printing conductive ink materials that are semi-solid. These droplets of ink are likened to snowballs by the company as they form on top of each other.

However, this new research from Beijing uses an injecting technique to form liquid metal channels in a flexible 3D printed part.

Research findings

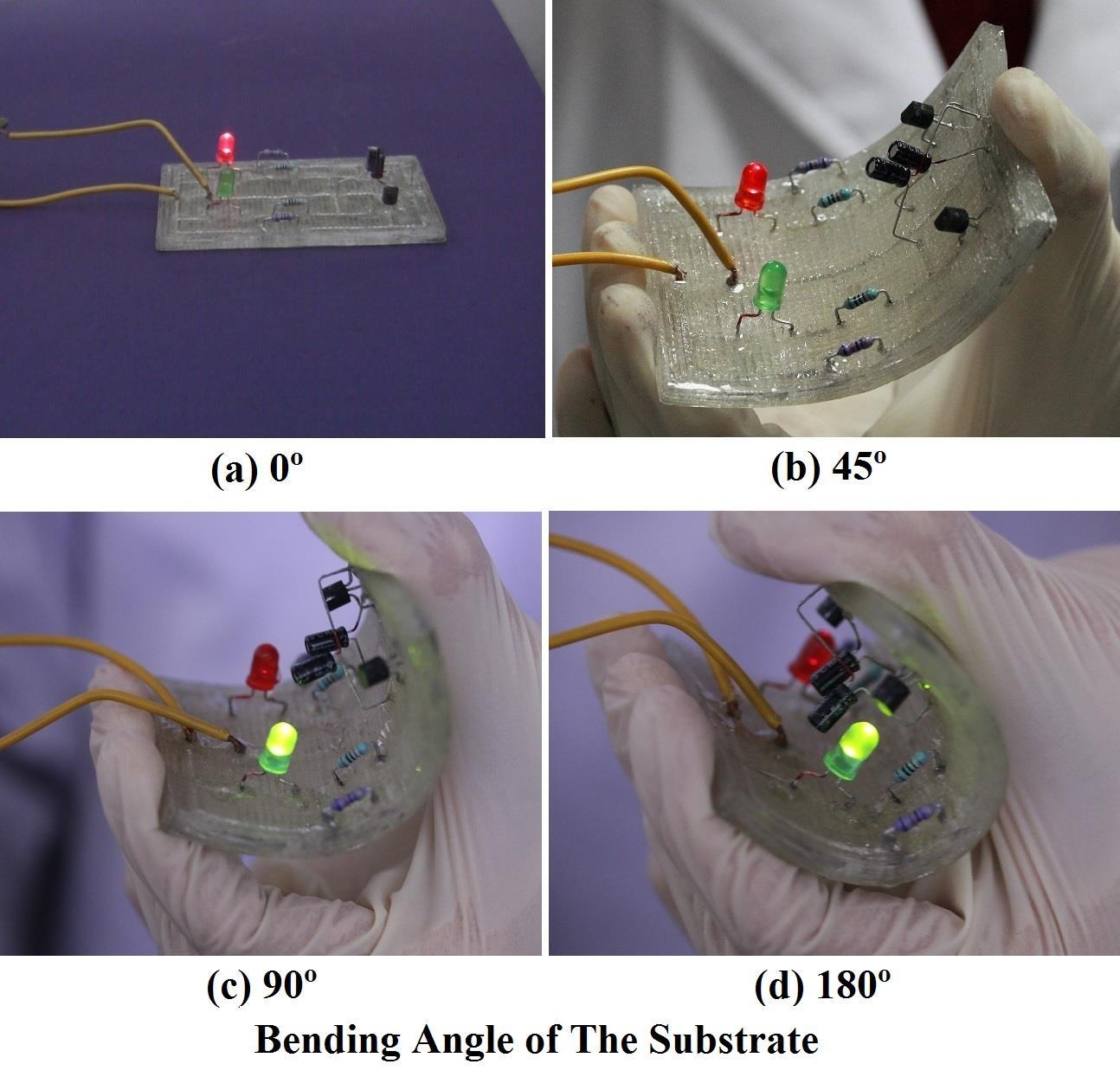

The researchers created a functional probe signal circuit using their technique. Furthermore, the structure they created was also very flexible. As they state,

A probe signal circuit has been fabricated to demonstrate the ability of injecting and packaging liquid metal into 3D printed structures for functional electronics.

The paper, ‘3D printing for functional electronics by injection and package of liquid metals into channels of mechanical structures’ is published in the Materials & Design journal. The research was conducted by Yong-Ze Yua, Jin-Rong Lua and Jing Liu as part of a collaboration between the Chinese Academy of Sciences of Beijing and Tsinghua University.

Future applications

Following the success of this initial study, the researchers state that,

Future work will focus on further improving the printing resolution and exploring new materials to facilitate the application of 3D printing technology in producing functional electronics for medical devices, wearable and flexible robots.

As the researchers conclude, there are a wide array of applications for this technology. Further work will seek to refine the method, particularly with its flexible characteristics.

Sign up to the 3D Printing Industry newsletter for updates on 3D printed electronics news. Let us know your thoughts in the comments below and make sure to follow us on twitter and Facebook.

Featured image shows the working circuit with bending angle of the substrate from 0 to 180º via Materials & Design.