IP protection is one concern that could stilt the growth of additive manufacturing for sensitive applications in high value industries such as aerospace, automotive and defence.

Protection methods under investigation include embedding quantum dot signatures, microstructural manipulation and advanced encryption of the digital design files.

The solution proposed by Dr. Sharon Flank et al. from InfraTrac, is to add spectral signatures to the 3D printed parts that can only be read via x-ray. This technique is more cost effective than some of the other methods in experimentation as it can be conducted using off-the-shelf devices.

The latest research into the method has been conducted in collaboration with the Penn State’s Center for Innovative Materials Processing (CIMP) and results have been published in the 3D Printing and Additive Manufacturing journal.

Leaving metallic fingerprints

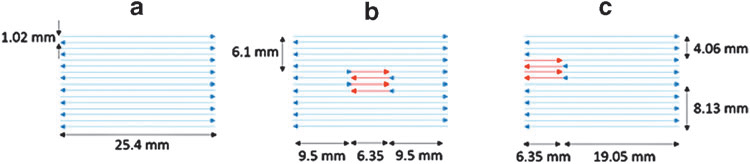

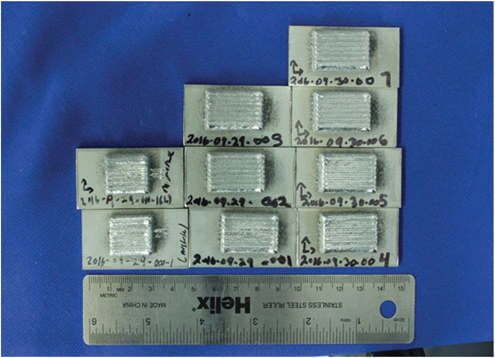

The most effective 3D printing method for chemical tagging of parts is directed energy deposition (DED) as it allows the use of multiple metals. In InfraTrac’s study, an Optomec M7 LENS system is used to 3D print titanium alloy samples. Chemical taggants are added to the parts at different depths, and scanned using x-ray fluorescence (XRF) spectroscopy analysis in lab conditions.

An advanced game of Battleship

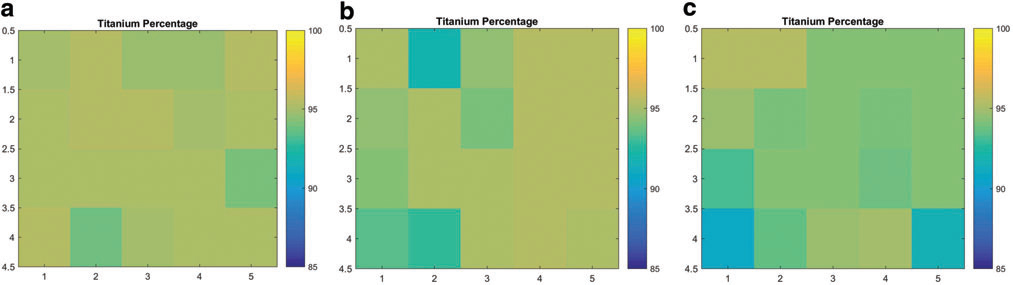

Results show that taggants on the surface of parts, though invisible to the naked eye, can easily be detected by XRF. 250 μm deep into the titanium sample however, the taggant becomes harder to differentiate.

A number of possible improvements are identified by the team to enhance the “smearing” effect in titanium, as a soft metal, that may cause poor clarity. As an example, Flank et al. suggest that “machining/grinding with sufficient lubrication or the use of an etchant, can reduce the effect of smearing.”

The researchers state that “These results are encouraging.”

“Preliminary results suggest hat not only can a taggant mix be detected but also can be hidden in a specific predetermined position, as in a game of Battleship.”

“Moreover, it can be quantitated as well so that a counterfeiter attempting to replicate the fingerprint would have to know about it, find exactly which spot it is in, and replicate its depth and composition correctly, along with matching the composition of

the matrix materials.”

For more research updates, follow 3D Printing Industry on Twitter, like us on Facebook and subscribe to our free newsletter. You can also register your interest for 3D printing jobs here.

Featured image shows DED in Optomec’s LENS technology as used in the InfraTrac study. Screengrab via Optmec on YouTube