In October 2018 independent tooling manufacturer Wilson Tool International launched its own 3D printing division: Wilson Tool Additive. Now, in a new case study, Carbon has confirmed that it has been providing Wilson Tool International with its Digital Light Synthesis (DLS) technology, both to produce custom tooling for the company and provide a service to its customers.

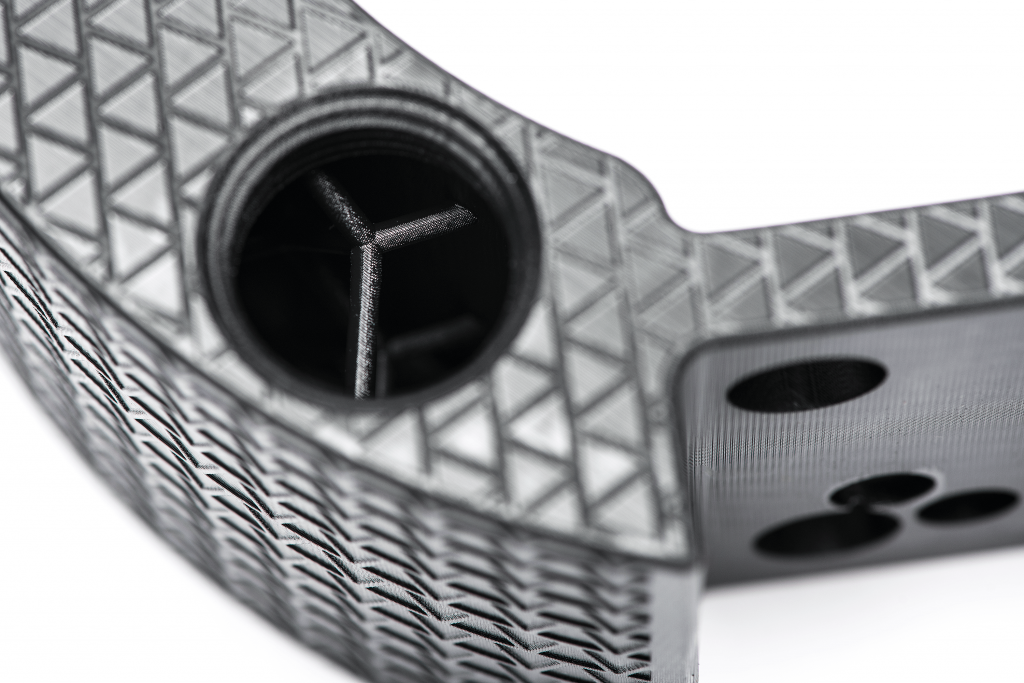

The product of the partnership between these two companies is evidenced in the production of a series of QuickTap™ oil reservoirs made from Carbon RPU 70 (Rigid Polurethane).

The metal alternative

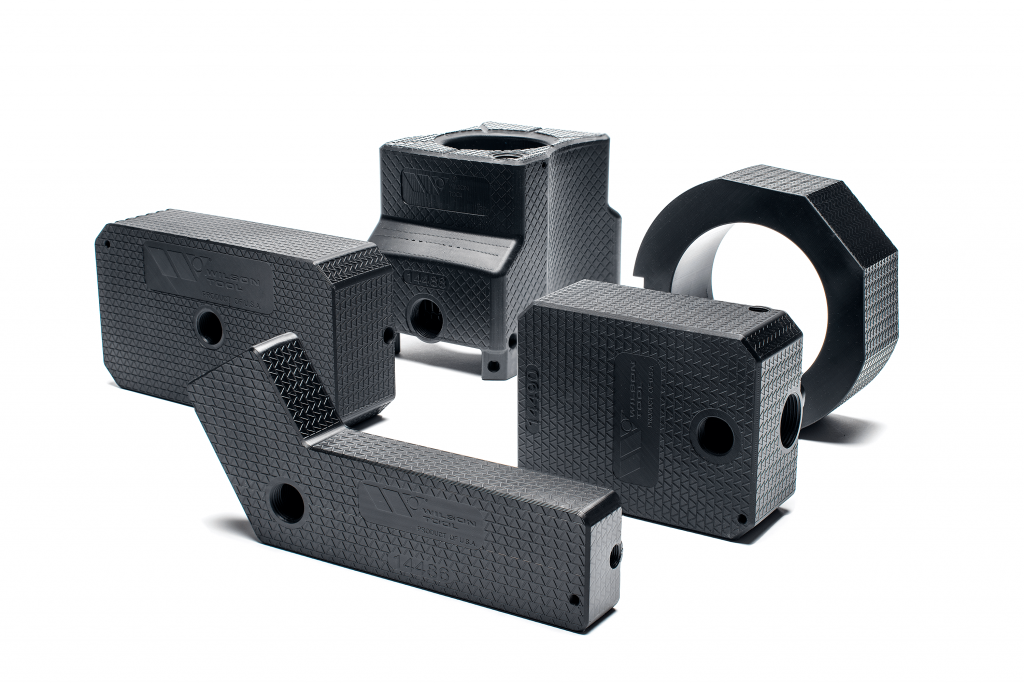

QuickTap™ is a family of tapping tools produced by Wilson Tool International for punching holes in sheet metal. Each QuickTap™tool is supported by an oil reservoir, which comes in six different configurations. In order to fulfil spare part supply to its customers, Wilson Tool International was keeping a large physical inventory of these tanks. Initially, they were also made from nine cold-rolled steel components.

To reduce the impact of these measures and the associated cost of traditionally produced oil reservoirs, Wilson Tool International identified Carbon DLS technology as an alternative method of fabrication.

A 60% reduction in cost

Through design for additive manufacturing, Wilson Tool International was able to produce oil reservoirs in a single part, reducing the risk of leakage and failure at the joins between components. The 3D file of these parts also means that the company can now stock a digital, rather than physical, inventory of the parts eliminating the cost of storage and leaving the part open to quick iterations in the future.

Having proved the repeatability of the oil tanks in RPU 70, Carbon explains “Wilson Tool International qualified the part across all criteria, demonstrating that it was printable, functional, and up to 60% less expensive per part.”

In addition, “The parts’ lead time could be cut by up to 50% and did not pose the destructive hazard that the metal ones did when they were not installed properly.”

Now, Wilson Tool International is set to launch a range of QuickTap™ tapping tool tanks with designs based on Carbon technology.

Brian Lee, Director of R&D and Technology Solutions at Wilson Tool International, concludes, “We knew additive manufacturing could offer us new paths in industrial tooling,”

“Our experience with the oil reservoir demonstrated that Carbon’s process and materials offer fundamentally new applications and capabilities.”

Wilson Tool Additive

At Wilson Tool International, 3D printing is offered by Wilson Tool Additive in the BEND3D and SOLV3D service lines. BEND3D is the company’s solution for producing custom press brake tooling, and is serviced by FDM technology. SOLV3D is the company’s service for other, more complex parts. Seemingly, this service is fulfilled by Carbon DLS technology or, as Wilson Tool Additive terms it: “Grown plastic” 3D printing.

Recently, Carbon has been on a drive toward the medical and dental markets. In June 2018 the company announced a partnership with National Dentex Labs (NDX), to install Carbon M2 3D printers in its facilities across America. In September, Carbon launched its first medical-grade material, Medical Polyurethane 100 (MPU 100). In addition, the company confirmed a partnership with Chicago-based 3D printing service bureau and “Industry 4.0 lighthouse” Fast Radius.

3D Printing Industry will be getting all the latest news from Carbon next week at Formnext in Frankfurt. To be the first with this news and more subscribe to the 3D Printing Industry newsletter, like us on Facebook and follow us on Twitter.

Search open opportunities and apply with 3D Printing Jobs. You can also make a profile to advertise your latest vacancies.

Featured image shows a Wilson Tool Internation QuickTap™ oil reservoir made from Carbon RPU 70. Photo via Carbon