Belgian software and 3D printing service provider Materialise has conducted a survey to determine the interest and attitudes of Chinese manufacturing companies towards 3D printing.

From the results of the survey, it is suggested that China is doubtful about 3D printing’s readiness for manufacturing end products. Instead, the country is focused on utilizing the technology for prototyping purposes.

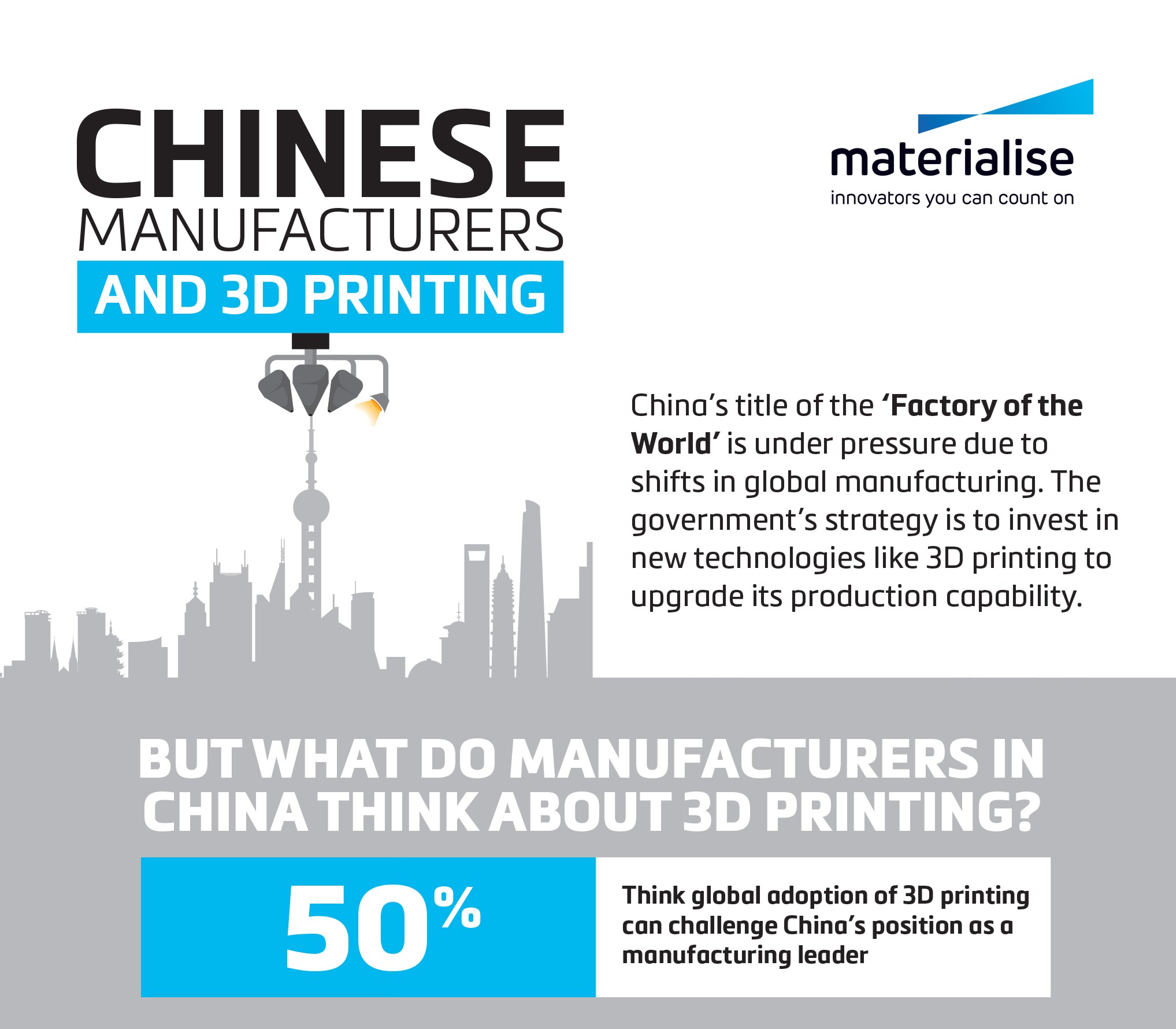

Materialise also notes that China, known as the factory of the world, is facing increasing competition from the global adoption of 3D printing, which respondents believe can challenge China’s position as a manufacturing leader.

“For many years, China has been considered to be the factory of the world because of its great efficiency and capability in producing goods and its export-oriented transport infrastructure,” explains Stefaan Motte, Vice President and General Manager of the Materialise software division.

“Today, China faces increasing competition from both newly emerging economies and highly-industrialized countries in an attempt to take a larger slice of its low-cost manufacturing base.”

The advantages of 3D printing for Chinese manufacturers

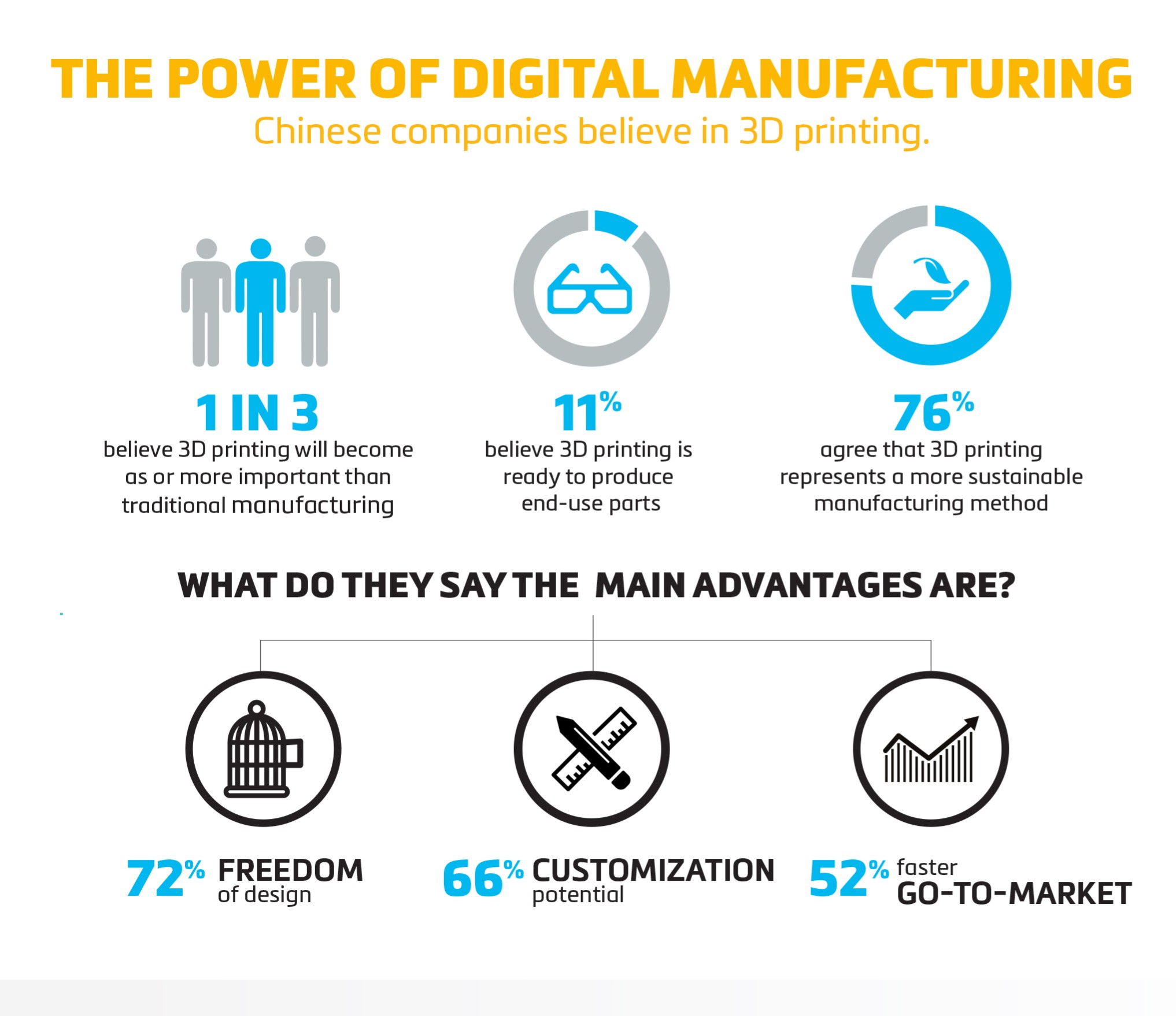

Although they don’t think the technology is ready for final production, 30 percent of Chinese manufacturers do believe that 3D printing will become as important, if not more so, than traditional manufacturing methods. 7 percent of those surveyed also believe that 3D printing will even replace those traditional technologies.

When questioned on the advantages offered by 3D printing, 72 percent of Chinese manufacturers listed freedom of design as the most significant benefit, followed by customization (66 percent), and the ability to bring products faster to market (51 percent).

Despite these advantages, Chinese manufacturers remain skeptical about 3D printing for end-use products, considering the technology more suitable for rapid prototyping, as users can print in small batches and easily make slight design changes. 11 percent of the Chinese manufacturers surveyed by Materialise believe 3D printing is ready for the production of end-use products, compared to 64 percent that think it is mature enough for manufacturing visual prototypes. A large swath (76 percent) do agree however that 3D printing represents a more sustainable way to manufacture products, suggesting that the additive production process will become increasingly relevant as manufacturers seek to reduce their waste.

Can 3D printing move from rapid prototyping to end-use production in China?

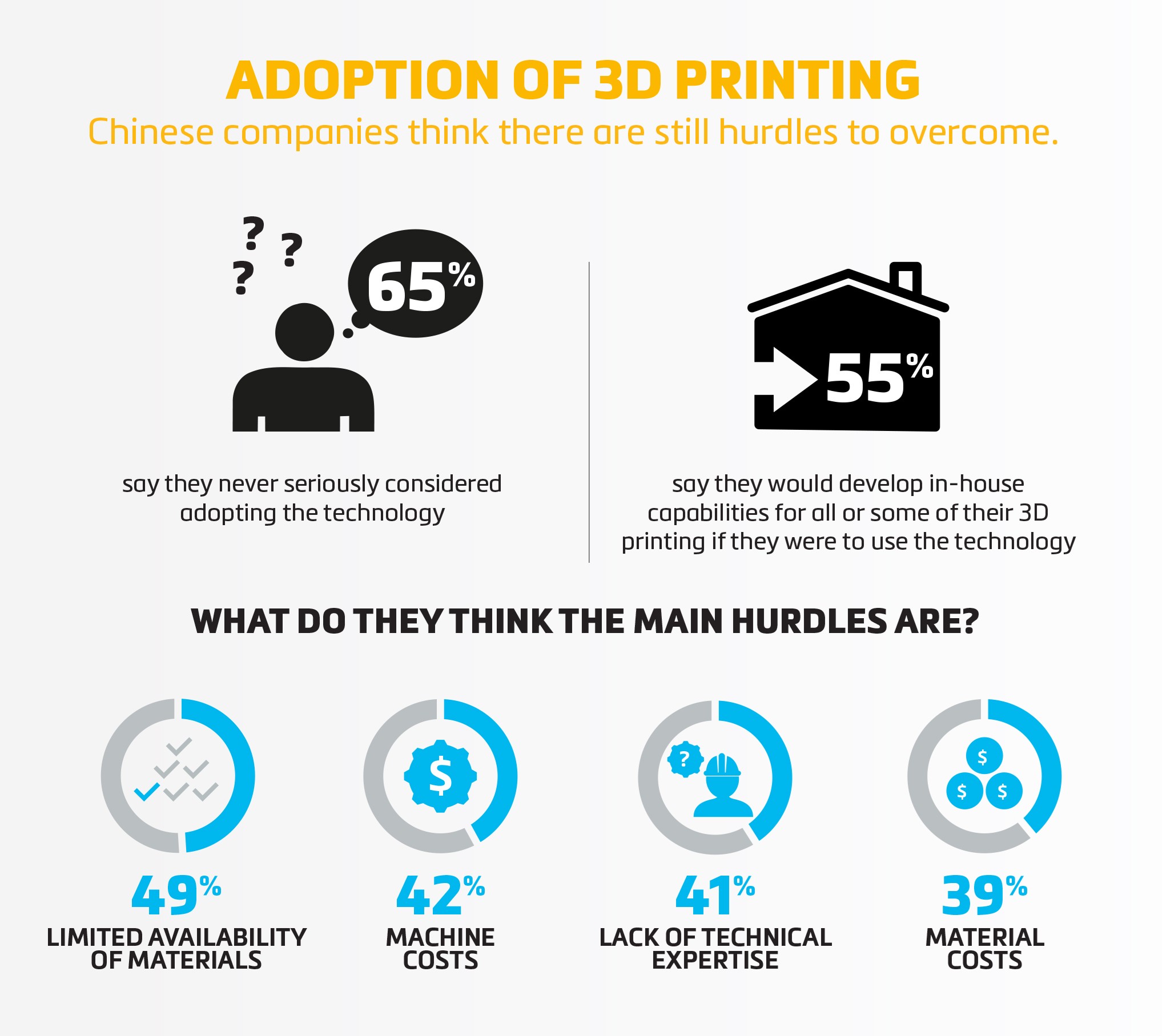

When questioned on what needs to be done to increase the adoption of 3D printing, 49 percent of Chinese manufacturers stated that the limited availability of usable materials is still a major hurdle. Other barriers listed by the respondents include the cost of machines (42 percent) and the cost of materials (39 percent).

Significantly, 41 percent also admitted that a lack of technical expertise remains an obstacle to increased adoption of 3D printing. Materialise suggest that this could explain why over half (65 percent) of Chinese manufacturers have not seriously considered adopting the technology, while only 15 percent have. Instead, 44 percent of the survey respondents believe that outsourcing 3D printing operations to a service provider is the preferred model for Chinese manufacturers.

This does not mean that Chinese manufacturers aren’t willing to develop 3D printing capabilities in-house, according to the survey. 40 percent of the respondents would choose a hybrid model where the 3D printing process chain is divided between in-house operations and external service providers.

Increasing adoption of 3D printing in China

Materialise conclude that its survey shows Chinese manufacturers are aware of the unique design and production advantages offered by digital manufacturing. However, as global adoption of 3D printing for manufacturing purposes increases, thanks to recent technological advances and its unique design and production capabilities, China remains focused on 3D printing as a prototyping technology. This is despite 50 percent of the respondents admitting that the global adoption of 3D printing can challenge China’s position as a manufacturing leader. Furthermore, over 40 percent think that 3D printing has the potential to impact the global distribution model of goods with localized manufacturing.

“China still holds a competitive edge in manufacturing,” adds Motte. “And I believe the country will remain a global manufacturing powerhouse for the foreseeable future. However, China understands that it needs to lift the game on its manufacturing competitiveness to face increasing competition and to move away from being the world’s low-cost workshop. 3D printing plays an important role in this plan.”

Initiatives have been established to help fuel the growth of 3D printing in China. For example, the Made in China 2025 strategic roadmap is a government plan issued in 2015. It aims to upgrade China’s manufacturing competitiveness by investing in advanced technology and preparing the future workforce.

3D printing is considered a significant element of the roadmap, with an Additive Manufacturing Industry Development Action Plan created by China’s Ministry of Industry and Information Technology (MIIT) forming part of the Made in China 2025 initiative. The Action Plan, established in 2017, has called for an additive manufacturing industry exceeding 20 billion Renminbi (US$3 billion) by 2020.

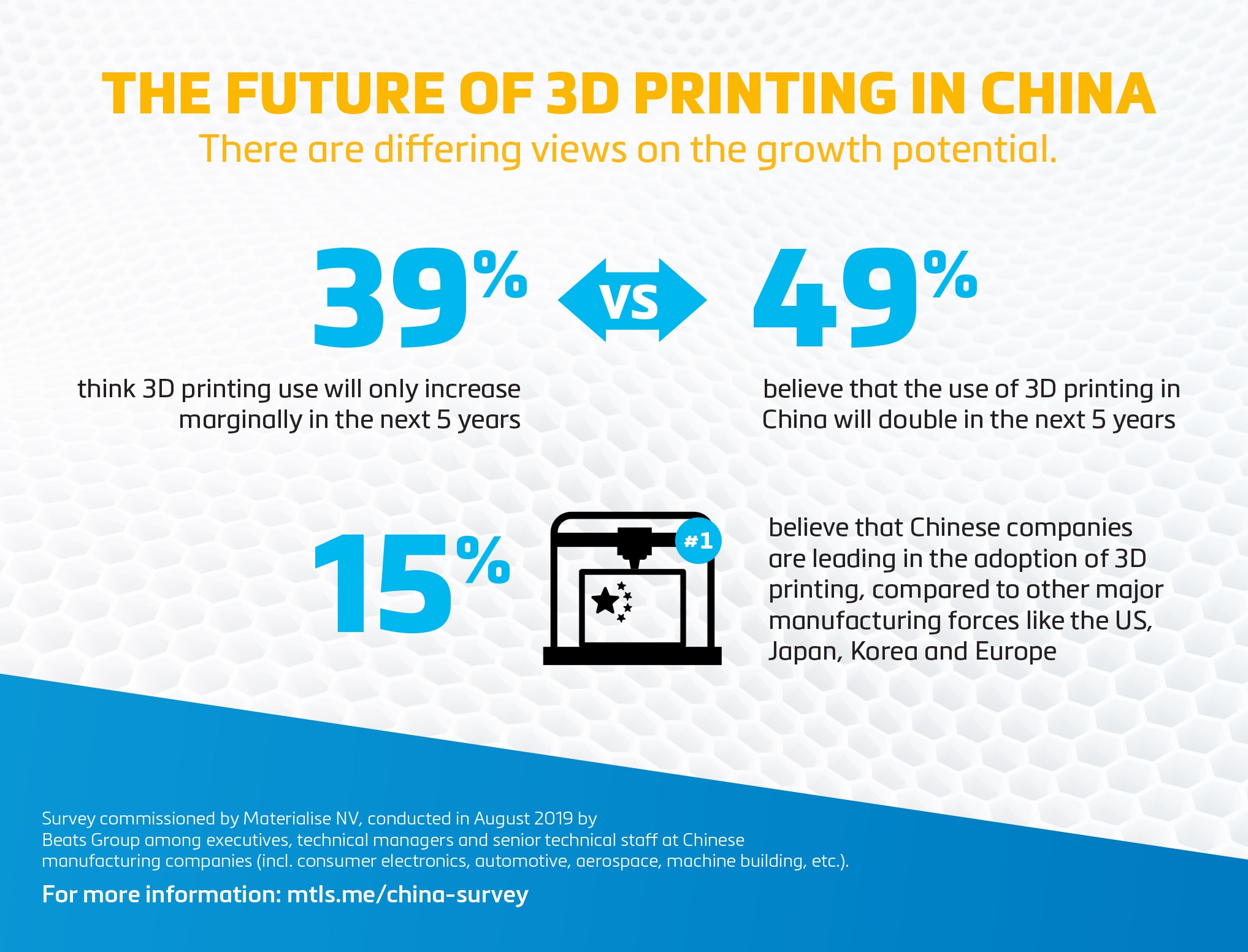

70 percent of Chinese manufacturers believe that smart manufacturing initiatives like Made in China 2025 can influence the adoption of 3D printing, however only 49 percent think that 3D printing usage will double in the next 5 years. Motte comments that, alongside initiatives like Made in China 2025, major 3D printing industry firms can help to spur on adoption of 3D printing in China as well: “We believe there is an opportunity for industry leaders like Materialise to collaborate with Chinese manufacturers to discover the potential of 3D printing end-use products, to identify meaningful applications and to stimulate adoption by removing some of the remaining hurdles.”

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows installations of HP Jet Fusion Printing Systems at the Lanwan Intelligence – HP Multi Jet Fusion Technology Mass Manufacturing Center in Foshan, China. Photo via HP Inc.