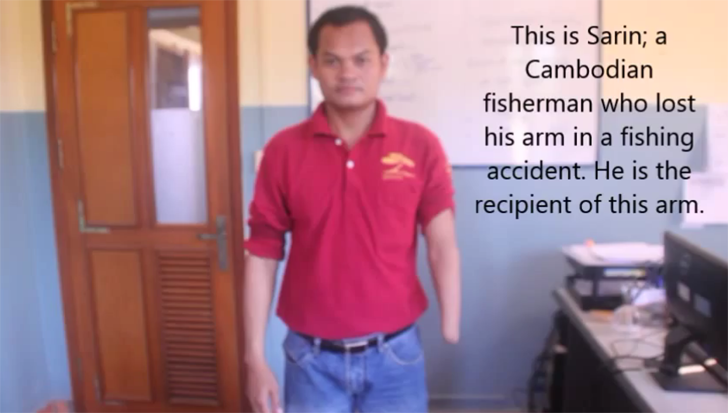

3DLifePrints, a Kenya-based enterprise that specializes in delivering low-cost 3D printed prosthetics to amputees in developing and emerging nations, has just published a video of the first fully flexible prosthetic arm, 3D printed for Sarin, a Cambodian fisherman who had lost his left arm and hand in a fishing accident.

Basing its research and work upon an extensive network of contacts through several emerging nations between Africa and Asia, 3DLifePrints has focused on truly bringing prosthetic manufacturing capabilities to the places where people need them most, understanding the specific local necessities, both in terms of functionality and aesthetics.

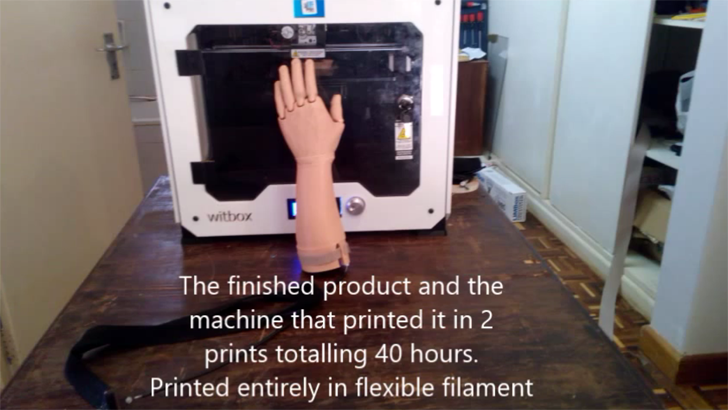

Developing a fully flexible prosthetic hand, while significantly more complex to produce, can offer many advantages in terms of making the prosthetic more similar to a real hand, in form and function. This particular prosthetic system, which also includes a harness to activate the mechanical grip, only cost $49 to produce and 3D technologies play a role in the 3D scanning of Sarin’s remaining limb, as well, in order to make the prosthesis fit properly.

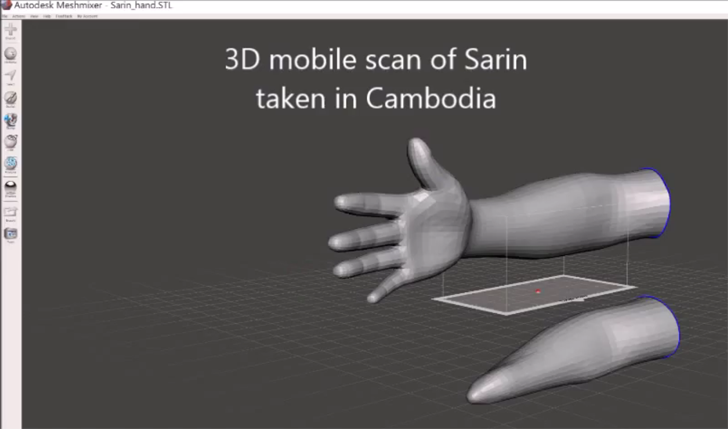

The mobile 3D scan of Sarin was taken in Cambodia and his limb 3D printed in nylon, while Recreus’s flexible filament was used for the hand. 3D printing was carried out on a DeltaWASP 2040 and a Witbox 3D printer. A 3D scanner was also used to add more realistic details to the outer surface of the hand. Other components were created with locally sourced break cables (for the gripping mechanism), fishing wire (to connect all five fingers to one cable), velcro, and a nylon strap.

Summing up the $5 for the harness strap, $6 for the break cable, $32 for the filaments, $2 for the velcro, and $2 for the fishing wire, the total is only $49, but the results are comparable – or even superior – to much more expensive, traditionally manufactured prosthetic products. The video below shows what has been achieved. The fact that real innovation in this field is coming for Cambodia is yet another practical demonstration of the potential of distributed manufacturing.