Already incredibly versatile, rechargeable lithium-ion batteries (LIBs) are reaching new levels of flexibility thanks to 3D printing.

Using a desktop 3D printer and PLA filament, researchers at Texas State University and Duke University, North Carolina, have found a cost-effective way of fashioning LIBs into wearable devices and coin cell batteries.

A study of the process has been recently published in ACS Applied Energy Materials journal.

PLA batteries?

Though an unconventional battery material, PLA is chosen by researchers in this study because, firstly: it is one of the cheapest and most common 3D printer materials, and secondly: it is easy to work into any shape your required.

The main barrier here however, is that PLA filament is not a natural ionic conductor. One of the important discoveries in DukeU and Texas State’s research was how to overcome this challenge – a condition met by infusing PLA filament with LiClO4.

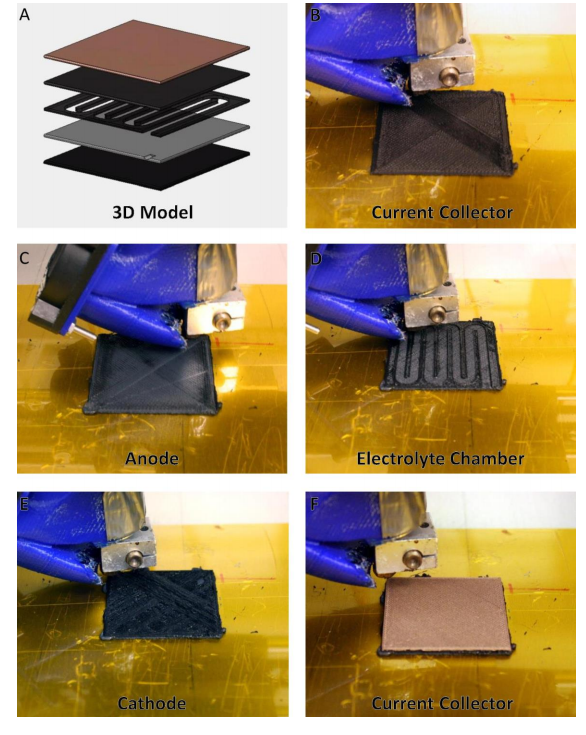

Next, it was necessary to determine the appropriate material combination to turn 3D printed PLA samples into anodes and cathodes with high capacity. Of the trial compositions, the research states, “The highest capacity was obtained with lithium titanate and graphene nanoplatelets in the anode, and lithium manganese oxide and multiwall carbon nanotubes in the cathode.”

Once formulated, the respective PLA anodes and cathodes were made using an unmodified desktop 3D printer from award winning developer Prusa Research.

Streamlining electronic design

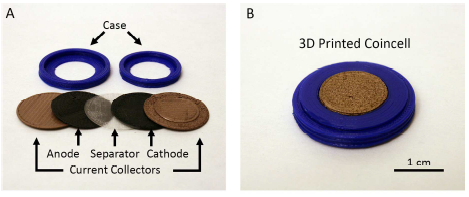

A coin cell was chosen as the first proof of concept sample. Though this is not the first time enhanced PLA filament has been used to 3D print coin cell batteries, the DukeU and Texas State project presents a novel advancement in its other samples.

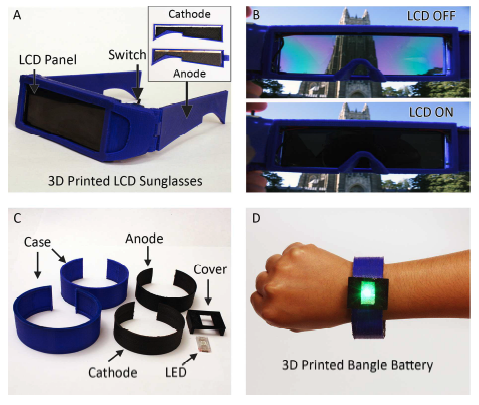

Through further experimentation, the team succeed in incorporating 3D printed anodes and cathodes into the design of darkening LCD lens sunglasses, and a light-up bangle battery. The remarkable feature of these designs is that the 3D printed LIBs are perfectly concealed first, in the arms of the glasses, and second, in the wrist band of the bangle.

In summary, “These results should benefit those seeking to create energy storage materials and devices that can be 3D printed to create batteries in arbitrary shapes.”

3D printed batteries

Elsewhere, at Brunel University London, researchers are seeking commercial applications for their 3D printed flexi-batteries integrated into wearable chargers. In July 2018, Carnegie Mellon University (CMU) and Missouri University of Science and Technology collaborated on a study termed “a major advance in 3D batteries.”

“Three-Dimensional Printing of a Complete Lithium Ion Battery with Fused Filament Fabrication” as discussed at length in this article is published online in ACS Applied Energy Materials journal. It is co-authored by Christopher Reyes, Rita Somogyi, Sibo Niu, Mutya A. Cruz, Feichen Yang, Matthew J. Catenacci, Christopher P. Rhodes and Benjamin J. Wiley.

For all the latest additive manufacturing research subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook. Seeking jobs in academia? Create a free profile on 3D Printing Jobs, or advertise (for free) to find expertise in your area.

Featured image shows a fully-3D printed bangle battery with integrated LED light. Photo via ACS Applied Energy Materials