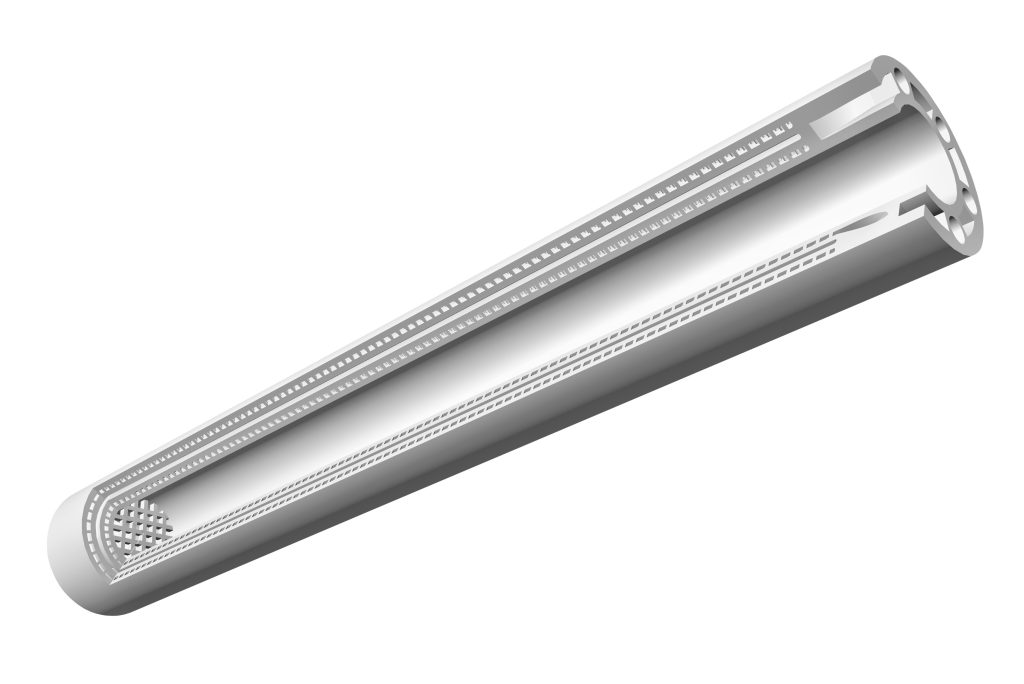

Bosch Advanced Ceramics, together with chemicals firm BASF and the Karlsruhe Institute of Technology (KIT), has developed what it claims is the world’s first 3D printed microreactor made of technical ceramic material.

A microreactor is a small-scale device designed to house and facilitate chemical reactions. To withstand the often extreme conditions created by these reactions, microreactors have to be stable in both high heat and corrosive conditions, but few materials offer such properties.

Bosch Advanced Ceramics has now combined its expertise in ceramics technology with additive manufacturing to enable the one-of-a-kind application. The microreactor is being used by BASF in day-to-day research applications, allowing the firm to monitor its chemical reactions under the necessary temperature conditions.

“To control and monitor a chemical reaction, a reactor needs to have hardness, heat resistance, and complex structures inside,” says Klaus Prosiegel, sales manager at Bosch Advanced Ceramics. “3D printed technical ceramics bring these excellent properties to the table.”

The market for technical ceramics

According to research firm Data Bridge, the global technical ceramics market is expected to be worth approximately €16 billion by 2029. The material class is highly versatile and in demand in a wide variety of sectors.

For example, in medicine, Bosch Advanced Ceramics’ materials are used to manufacture bipolar scissors capable of cutting tissue and stopping bleeding simultaneously. An electrical current running through the metal in the blades heats the tissue to seal it, while the technical ceramic acts as an insulator to stop the metallic blades from short circuiting. This can make surgery both safer and faster.

Similarly, in the energy sector, the firm’s technical ceramics offer excellent heat resistance and ion conductivity for use in fuel-cell stacks. The mobility industry often makes its distance sensors out of technical ceramics too, helping drivers park their cars in tight spots.

A 3D printed ceramic microreactor

Amid the plethora of advanced applications, Bosch recognized that technical ceramics could also make great reaction chambers. The challenge was to find a production process that could fabricate the complex structures necessary for this particular microreactor – structures that would otherwise be impossible using traditional manufacturing.

By opting for 3D printing, the partners found that the reactor required fewer raw materials and significantly less energy than a conventional large reactor. BASF is now using the 3D printed device to conduct smaller-scale experiments and extrapolate the results before moving on to larger-scale projects.

Prosiegel explains, “This is just like a chef trying out a new recipe on a small scale first before putting the dish on the menu.”

As far as next steps go, the partners now intend to 3D print another 10 to 20 reactors with the exact same design for BASF. Prosiegel also sees a bright future for technical ceramics in the chemicals sector as a whole, stating that every laboratory crucible is made of technical ceramics, after all.

This may be the first instance of a 3D printed ceramic microreactor, but the energy industry has certainly 3D printed reactor components before. Just last month, a set of additively manufactured fuel components were installed in nuclear power plants across Scandinavia. Named StrongHold AM filters, the nuclear fuel debris filters were 3D printed by Westinghouse Electric Sweden and are the first of their kind to be approved for end-use.

Elsewhere, the Seattle-based Ultra Safe Nuclear Corporation (USNC) recently licensed a novel method to 3D print components for nuclear reactors using refractory materials such as silicon carbide. Developed by Oak Ridge National Laboratory, the method combines binder jet 3D printing techniques with a chemical vapor infiltration process.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

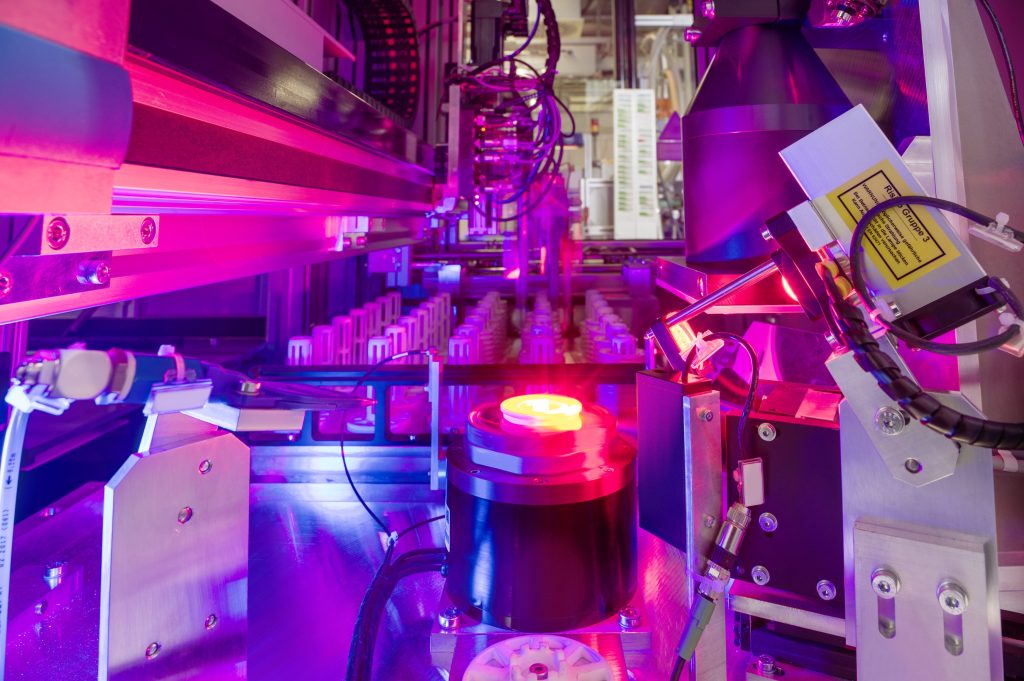

Featured image shows BASF monitoring a chemical reaction inside a visual inspection machine. Photo via Bosch Advanced Ceramics.