The multinational automotive BMW Group has invested €10 million (approximately $12.3 million) in an Additive Manufacturing Campus scheduled to open early 2019.

A 6,000 square meter facility, the new Additive Manufacturing Campus will focus on prototyping, series production of parts, and customized solutions for the automotive industry.

Udo Hänle, Head of Production Integration at BMW comments, “Our new Additive Manufacturing Campus will concentrate the full spectrum of the BMW Group’s 3D printing expertise at a single location,”

“This will allow us to test new technologies early on and continue developing our pioneering role.”

Pedal to the metal for 3D printing at BMW

According to BMW 3D printing is an integral part of research and development at the company. At sites in Spartanburg (U.S.), Shenyang (China) and Rayong (Thailand) BMW already uses 3D printing for prototyping purposes.

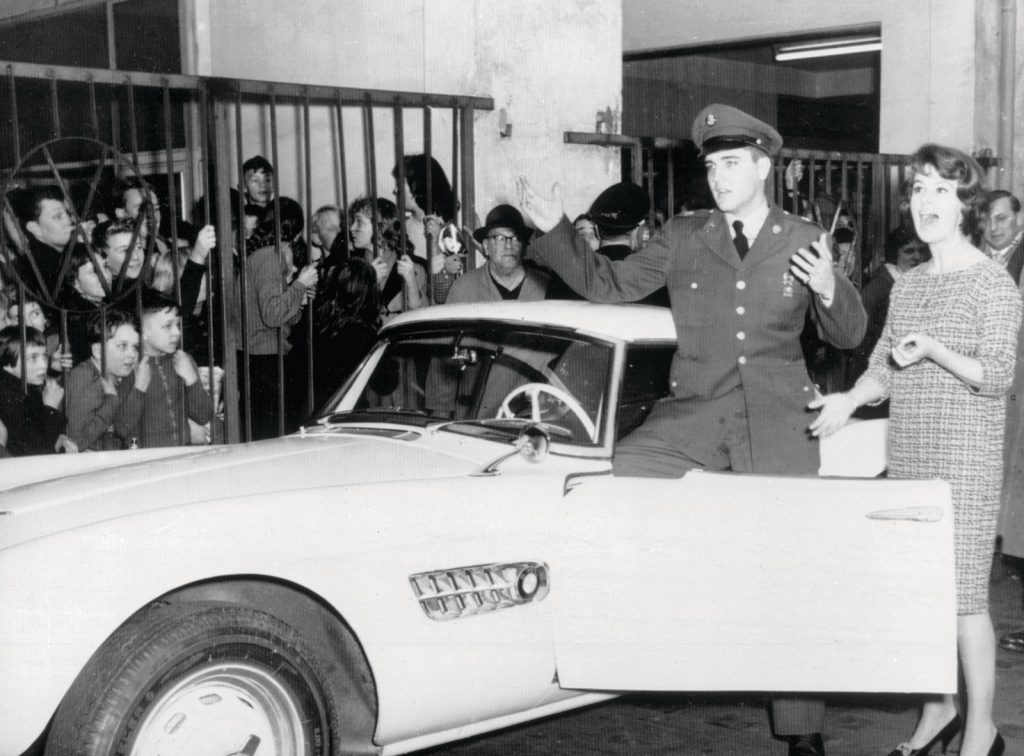

Recently, under the BMW Group umbrella, the MINI car brand introduced a commercial 3D printing service that allows customers to specify decals for the lights and dash of their cars. Fellow group brand Rolls-Royce has been applying 3D printing to the production of its bespoke vehicles. And the company has also applied 3D printing to the restoration of Elvis Presley’s BMW 507.

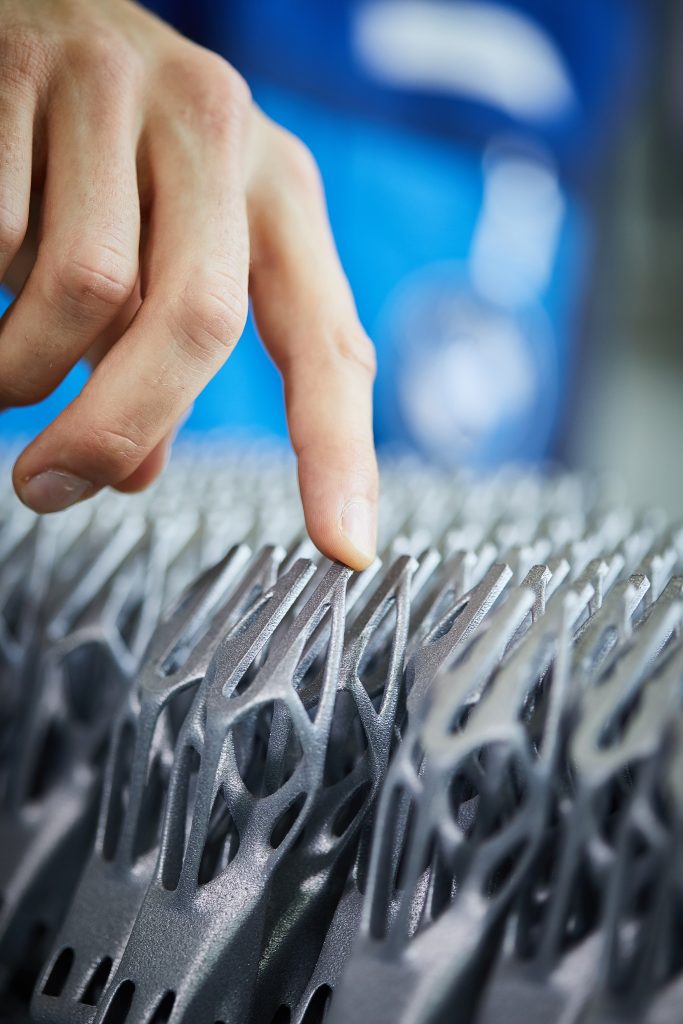

In 2017, the i8 Roadster became the first in-production vehicle at BMW to include 3D printed parts. According to Jens Ertel, Head of BMW’s Additive Manufacturing Center and director of the forthcoming Additive Manufacturing Campus, “With the BMW i8 Roadster, the BMW Group [also] became the first carmaker to 3D-print a production run of several thousand metal parts.”

The component in question is a palm-sized fixture used in the mechanization of the car’s soft-top. The i8 Roadster’s 3D printed tonneau cover – a cover for protecting unoccupied passenger seats – fixture is made from an aluminum alloy, significantly lighter and with greater rigidity than the injection molded counterpart.

Additive by association

Through related investment capital firm, BMW i Ventures, the BMW Group is also helping to advance 3D printing at enterprises including Carbon, Desktop Metal and on-demand manufacturing service Xometry, that recently raised $15 million in funding is round led by BMW i Ventures with GE Ventures and Highland Capital Partners.

2019’s Additive Manufacturing Campus in Oberschleissheim, north of Munich, will accommodate up to 80 BMW employees, with space for over 30 industrial systems for additive manufacturing in metal and plastic.

“Our new facility will be a major milestone in additive manufacturing at the BMW Group,” adds Ertel.

“The team there will evaluate new and existing technologies in both plastics and metals printing and develop them to series maturity. Our goal is to provide the optimum technology and process chain, be it for individual components, small production runs or even large-scale manufacturing.”

For more on the latest Trends in Additive Manufacturing for End-Use Production, revisit our guest article series on the topic here.

The race is on

Through the Next Gen AM project Daimler, parent company of Mercedes-Benz and Smart cars, is also ramping up its efforts toward additive manufacturing for series production.

3D Printing Industry Awards nominee Bugatti has been making headlines for the implementation of a 3D printed brake caliper in the $3 million Chiron.

Recently, South Korean Hyundai subsidiary Hyundai Mobis announced that it would be opening a specialized 3D printing lab for vehicle research and development.

To stay up to date with the launch of this center and other related news subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook.

Vote for automotive/aerospace application of the year and more in the 2018 3D Printing Industry Awards now.

Join our 3D printing jobs service for all the latest engineering, marketing, research, and management vacancies.

Featured image shows metal additive manufacturing at BMW. Photo via BMW Group