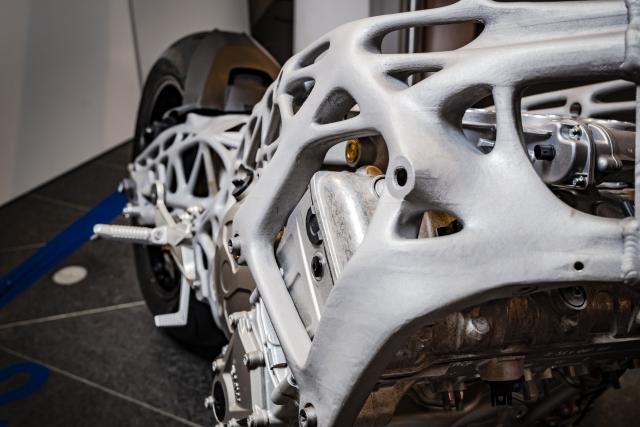

This week multinational automotive BMW Group invested €10 million (approximately $12.3 million) in a new Additive Manufacturing Campus in Germany. In the teaser for this new facility, discerning viewers may have noticed the 3D printed chassis of a BMW sports bike.

Made for the award winning BMW S1000RR motorcycle, the 3D printed chassis is a demonstration of possibilities yet to come from the company’s developing additive hub.

Record breaking bikes

The BMW S1000RR motorcycle was initially made for the 2009 Superbike World Championship and has been subsequently entered into races by multiple world championship, MotoGP and Isle of Man TT riders.

In 2014, Michael Dunlop made TT history taking home 4 wins when riding a S1000RR for BSB team Hawk Racing. Peter Hickman also won the Macau Grand Prix with the bike in 2015 and 2016.

The bike entered commercial production in 2010, and has undergone various iterations over the years to improve its performance.

Racing on air

As of 2016, the S1000RR production model has a wet weight (incl. fuel, lubricants, battery) of 207.7 kg. The race model, by comparison, has a wet weight of just 162 kg. With 3D printing, BMW could reduce the weight of the S1000RR even further, offsetting the weight of heavier components, and optimizing the design for rideability.

The 3D printed S1000RR was demonstrated to visitors at BMW’s Digital Day in Mallorca.

In the concept model, the frame and swingarm have been 3D printed. The method used is a powder-based selective laser melting technology. Topology optimization, and potentially generative design, has been used to create the bike’s “organic” look. Strength is managed along key supportive points on the frame.

Future motorcycles and sports cars

BMW’s Additive Manufacturing Campus is located close to the company’s Research and Innovation Centre in Munich. According to BMW, this facility develops and manufactures over 100,000 precision components each year, including discontinued car parts, plastic mountings and “highly-complex chassis parts made of metal.”

Small quantities of tailor-made or complex components are the facility’s main additive manufacturing output. The Research and Innovation Centre is also behind metal 3D printed fixtures for the in-production i8 Roadster.

The Airbus APWorks Light Rider is perhaps one of the most well-known examples of 3D printing in motorcycles. Independent motorbike manufacturers, like Barcelona’s BORN Motor Co., are also keenly adapting the technology for bespoke production needs.

Clearly invested in the technology, it will be interesting to see how BMW leverage additive manufacturing in the future.

To stay up to date with automotive applications and other related news subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook.

Vote for automotive/aerospace application of the year and more in the 2018 3D Printing Industry Awards now.

Join our 3D printing jobs service for all the latest engineering, marketing, research, and management vacancies.

Featured image shows BMW’s S1000RR 3D printed chassis. Photo via Visor Down