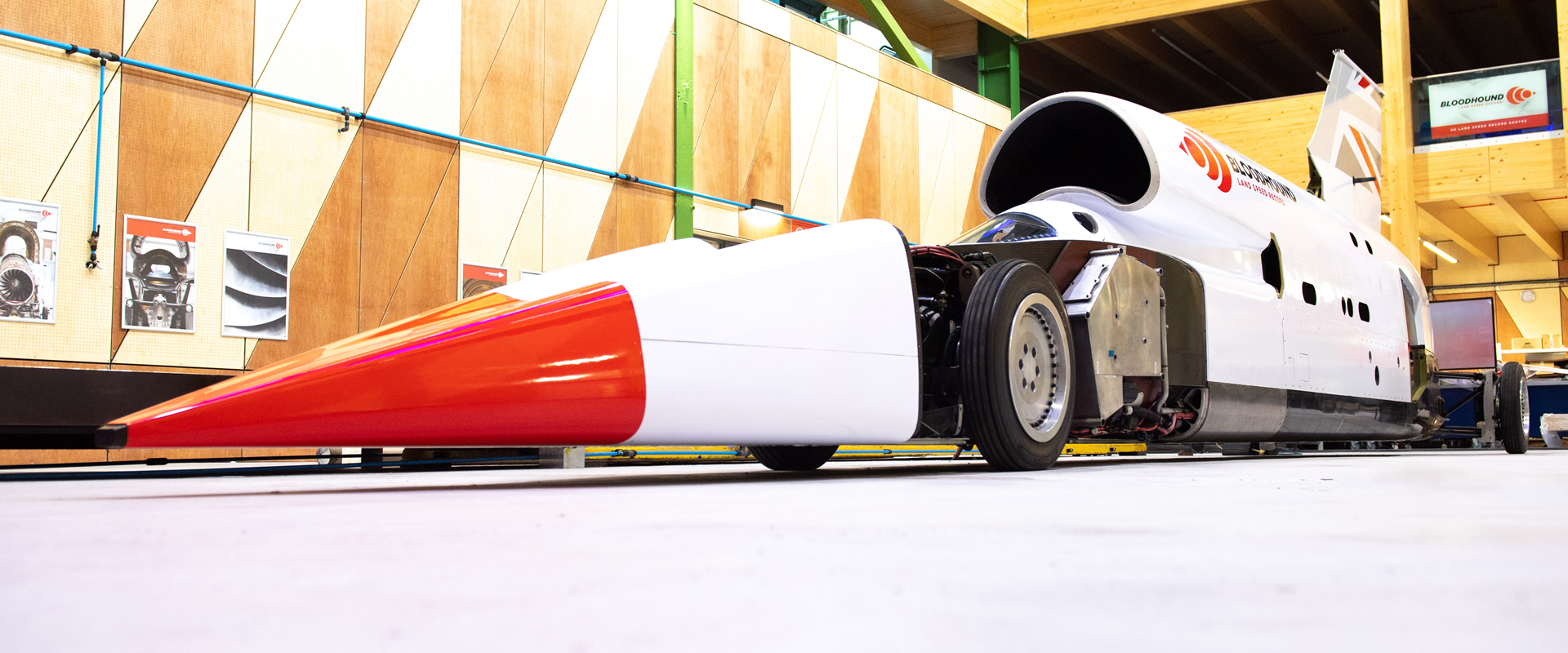

The Bloodhound LSR, a British supersonic land vehicle featuring 3D printed parts from UK-based additive manufacturing specialist Renishaw, is set to carry out its first run on a custom dry lake bed race track at Hakskeen Pan in the Kalahari Desert in October 2019. It has the target of reaching 500 mph, which is a key milestone in the team’s bid to set a new world land speed record by eventually reaching 1000 mph.

Previously named Bloodhound SSC, the project was relaunched in March 2019 after it was bought by Ian Warhurst, a businessman from Barnsley in South Yorkshire, in December 2018. Warhurst purchased the car with the intention of keeping the project afloat when development halted in October 2018 after failing to secure investment. “I’m thrilled that we can announce Bloodhound’s first trip to South Africa for these high-speed testing runs,” Warhurst stated.

“We’re running the car on a brand-new surface. The wheels have been designed specifically for this desert lake bed, but it will still be vital to test them at high speeds before making record speed runs.”

Renishaw 3D printing helping to break world land speed record

The new 500 mph speed tests set to take place in October later this year follows the previous runway trials of the vehicle that were carried out at Cornwall Airport Newquay in October 2017, where the Bloodhound was able to reach 200 mph. The 500 mph run was originally planned to take place at an earlier date, however the delays in funding pushed the test runs back.

As previously reported, Renishaw provided the Bloodhound with a 3D printed titanium steering wheel, air brake door hinges and a prototype nose tip, in order to help the vehicle achieve its goal of breaking the current land speed record, which stands at 763 mph.

Since the relaunch of the project in March 2019, significant attention has been given to the logistics of deploying the team and the car to the Kalahari Desert, and the transformation of the car from its runway design to the specifications required for high speed testing. Thus, the team has worked on upgrading the springs and dampers of the vehicle, as well as adding the parachute braking system, air pressure and load sensors, and a fire detection and suppression system. The record runs of the Bloodhound, where it is expected to reach 1000 mph, are scheduled to take place in late 2020.

Speeding into the digital era with 3D printing

It is said that the Bloodhound LSR team’s effort is the first attempt at breaking the world land speed record in the ‘digital era’. The previous record was set in October 1997, however, with the attempt being made by the Bloodhound in 2020, the team can make use of data captured from hundreds of sensors onboard the vehicle. This will be shared to engineers in real time, allowing them to observe the behavior of the car at unprecedented speeds.

The data capture and distribution will be tested at the 500 mph trials taking place in South Africa, allowing the team to prepare for the land speed record runs. It will be a full-dress rehearsal, where the team will be able to develop its operational procedures, practice working in the desert and test radio communications. “This world land speed record campaign is unlike any other, with the opportunities opened up by digital technology that enabled the team to test the car’s design using computational fluid dynamics (CFD) and that will allow us to gather and share data about the car’s performance in real time,” added Warhurst.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You

can also keep connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.