By now, anyone who’s been following 3D printing is already aware of Organovo, the biotech firm that is developing a method for 3D printing biological tissue. While the company has already partnered with some big names, like Autodesk and Pfizer, Dr. Patrik D’haeseleer and BioCurious, his community of biohackers have shown that bioprinting doesn’t require a big budget by building a bioprinter out of spare electronic parts. The best part is: all of the instructions to create your own can be found at instructables.com.

Though you might expect BioCurious to use the RepRap as a basis for its bioprinter, the group actually went on a different route, using recycled parts from scrapped electronics. First, they took a used HP 5150 inkjet printer and completely disassembled it. They then cleaned out the existing cartridges so that they could fill them with whatever material they planned to print with. In this case, they decided to print E.coli that had been genetically modified to glow – thanks to a “Green Fluorescent Protein” – onto an agar plate.

The resolution on the HP printer was, unfortunately, much too high, preventing any complex eukaryotic cell from passing through its 23 micron nozzle. So, D’haeseleer and his team turned to InkShield, an open source print head, which allowed for a much wider nozzle, proving that high resolution isn’t always right for every task. The motors for the XY axis were taken from an old CD/DVD drive – an idea inspired by a fellow DIY-bio group, Hackteria.

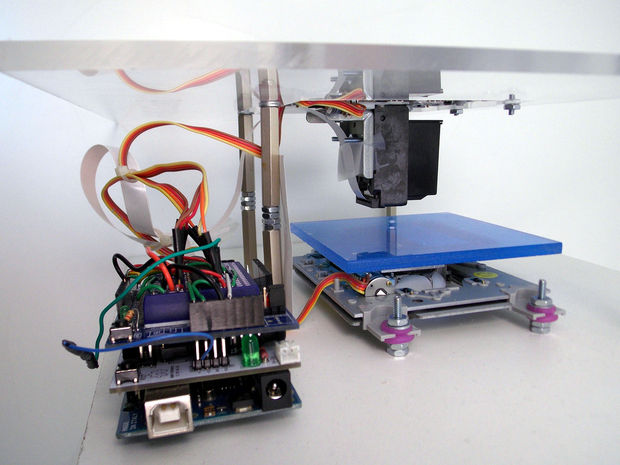

All combined, the parts to build the whole printer add up to about $150, with the CD/DVD drive moving the print platform, the InkShield print head depositing the E. coli ink, and an arduino acting as the gateway between the computer and the printer. Though the group only printed “I <3 Biocurious” in glowing E.coli, D’haeseleer, in his instructables directions, noted that the project might lay the foundation for further biological experimentation. With the bioprinter, he stated, one could potentially:

– Print gradients of nutrients and/or antibiotics on a layer of cells to study combinatorial interactions – or even to select different isolates from an environmental sample.

– Print patterns of growth factors on a layer of eukaryotic cells to study cell differentiation.

– Print two or more microbial species at different distances from each other, to study metabolic interactions.

– Set up a computational problem as a 2D pattern of engineered microbes on an agar plate.

– Study Reaction-Diffusion systems

– Print 3D structures by over-printing layers using the inkjet head. Now you can consider doing all the above in 3D!

– Print cell in a sodium alginate solution, onto a surface soaked in calcium chloride, to build up 3D gel structures (similar to spherification process in Molecular Gastronomy)

In many ways, bioprinting represents the holy grail of additive manufacturing – aside from, possibly, some sort of atom printer. By using a material that has its own, built-in, organic properties, bioprinters will be able to utilize the ingenious engineering of nature to create structures for human purposes, especially if we can master the process of printing DNA. I’m no scientist, but I do have an active imagination. I can envision a 3D printed home that can grow a weather resistant algae in the winter, to act as insulation, and shed it in the summer, to let air into your organic home. More realistically, bioprinting will lead to sustainable energy and quick vaccination production.

Sure, that’s probably years away, but groups like BioCurious represent a shift in the type of technology ordinary people will be using in the future. Apple may want you to picture a world of smooth, rounded plastic in all-glistening white, but the future may look something more like a David Cronenburg movie: part flesh and part electronic. And, as you can see from BioCurious’s bioprinter, it may not be done entirely by clean-cut corporations, but ramshackle communities. Already we’re seeing biohackers pop up in cities across the world who are intent on creating affordable ways to study biology in their own homes, developing iPhone microscopes and printable centrifuges. If the future of biohacking is anything like the history of computers, the devices we use in the next fifty years could be in us and not around us.

But, even if the bioprinter doesn’t turn us all into androids with magnets in our hands, it will at least decrease the cost of biological research significantly. Currently, the study of genetic material is a slow and expensive process, as DNA sequencing itself requires a lot of money and time. Printing DNA, however, would allow for researchers to create large batches with which to test hypotheses to their hearts’ content.