Betatype, a London-based additive manufacturing software company has released a case study showing that its software can double the production of 3D printed metal orthopedic implants. This is done with the help of Engine, a 3D printing workflow optimization software by Betatype which generates small-sized data files for efficient processing.

A case study, using Renishaw‘s RenAM 500Q powder bed fusion (PBF) printer Betatype shows how Engine realizes the potential of the metal printer to make orthopedic implants.

Processing large data

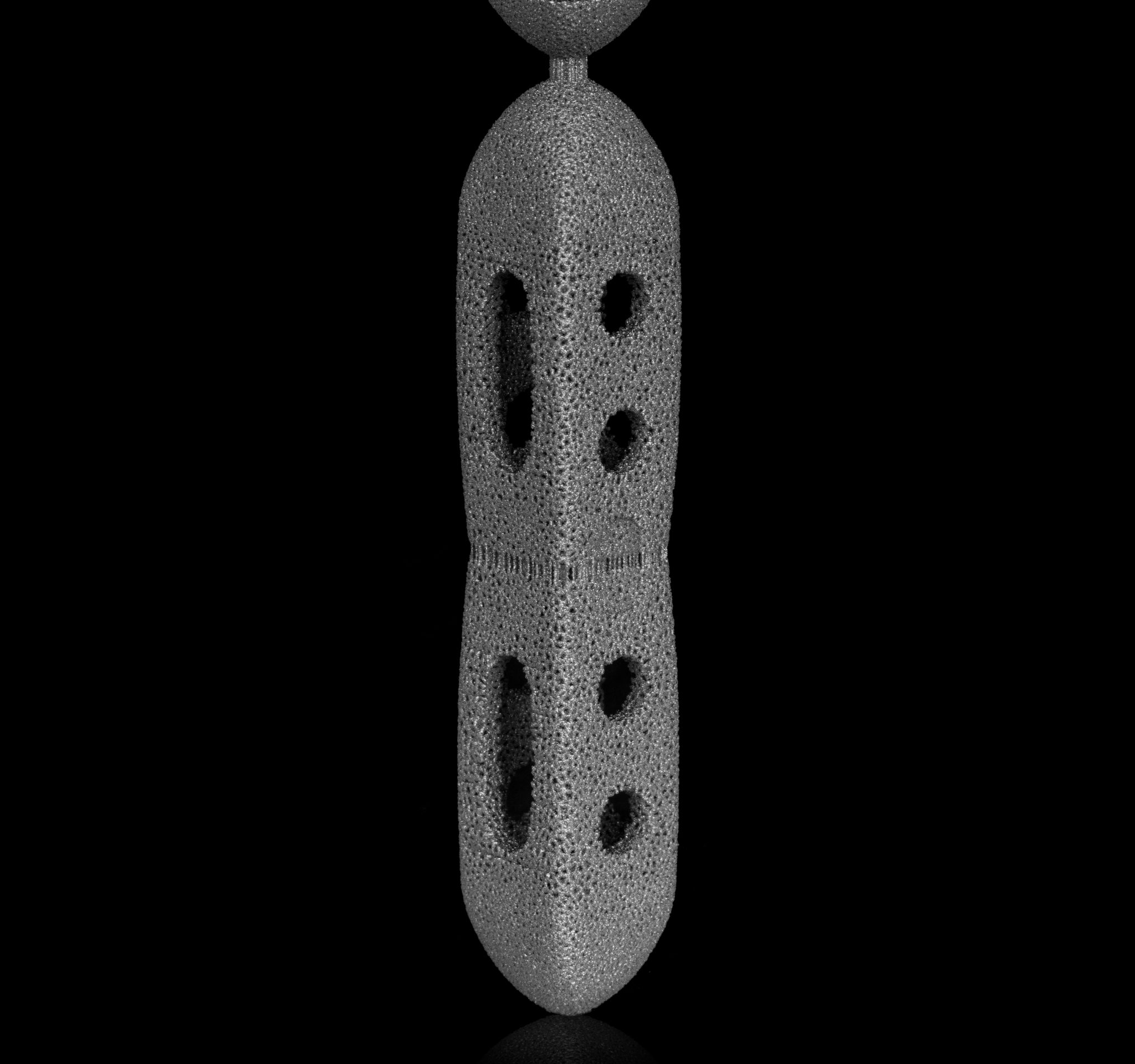

Models like orthopedic implants often have a complex geometrical structure. When orthopedic models are sliced for metal 3D printing, process parameters such as laser scanning path, laser power, and spacing are generated. And depending on the complexity of a model, the parameter data sent to the 3D printer can be very large. And large data sets can slow the printing process, as all machines have a limited CPU speed and RAM capacity.

Betatype’s Engine overcomes this limit by storing data in file formats which are lighter than a .stl file. These file formats include Betatype’s own ARCH format and LTCX file by nTopology, a New York-based software company. Even though both file formats carry the same information, they are 96% lighter than a CAD file.

Sarat Babu told us that, “In this particular case study nTopology was indeed used. Previously we have developed our own ossoeintegrative architectures for the orthopaedic industry.”

The ARCH and LTCX formats let designers make complex parts without producing massive size CAD files. The case study states: “a spinal cage model was only 8MB as an LTCX file compared to 235 MB as an STL file.”

According to Betatype, because of these factors, the Engine can handle large data sets at a high speed and manage them more efficiently than traditional software.

Stacking up

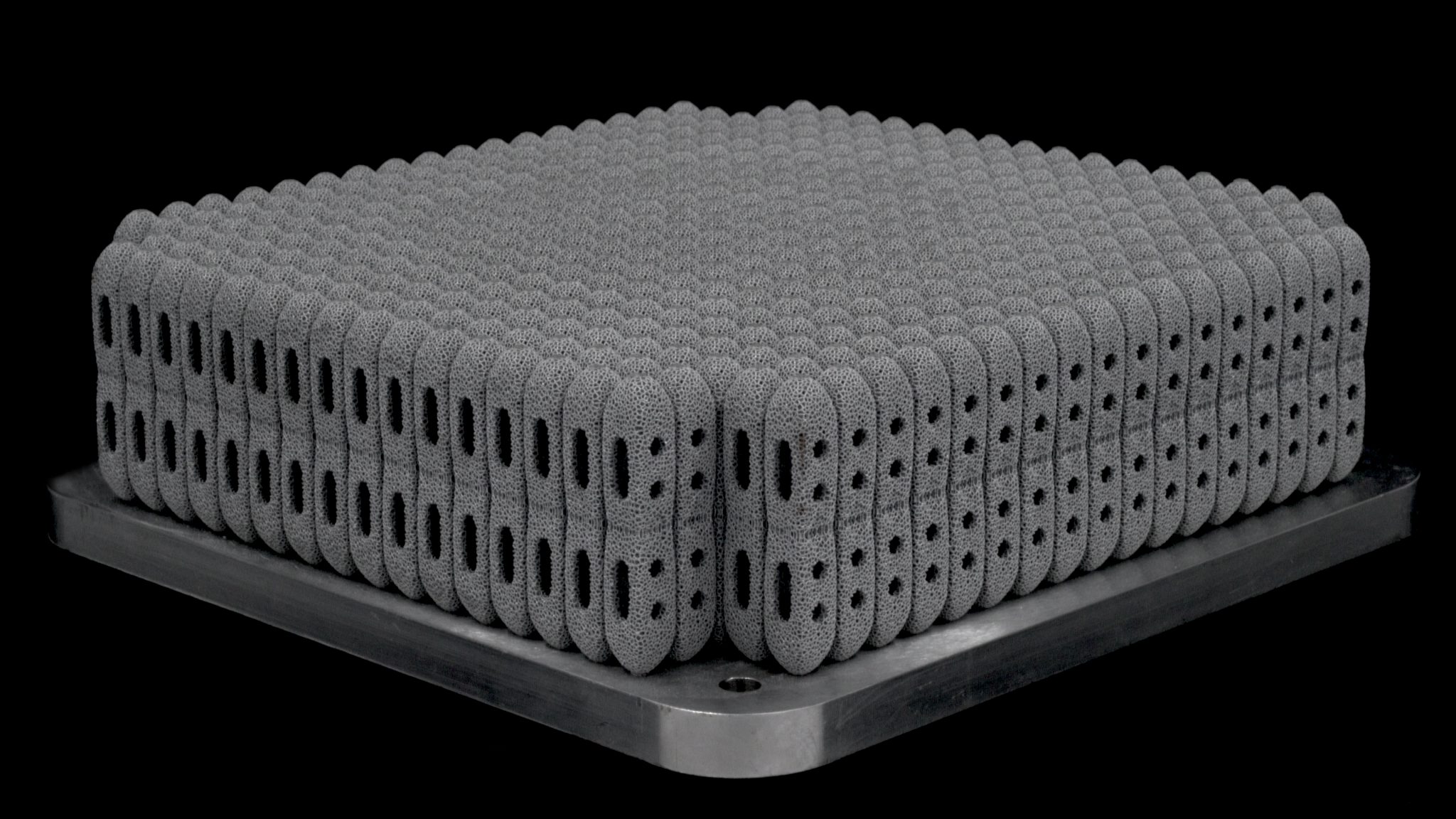

In addition to generating lightweight files, Engine can manipulate the data to make full use of the build volume of a 3D printer. It does this by stacking models on top of each other. These models are joined together by a support structure which can be easily removed by sandblasting techniques, in the post-processing stage. In the latest case study, Betatype 3D printed 800 lumbar cages using this method.

Furthermore, it was shown that build times can be reduced by as much as 40%, by optimizing the laser firing power and traveling distance. The final results showed that a part which usually takes about twenty-five hours can be 3D printed within 15.4 hours.

Elsewhere, 3D printed lumbar cages are proving an appealing commercial prospect. For example, the MOJAVE spinal support implant made by K2M gained FDA approval in 2017. K2M was acquired by Stryker in 2018 for $1.4 billion. Last year also saw Johnson & Johnson purchase EIT’s 3D printed spinal implant range.

Nominations for 3D Printing Awards 2019 are open. Please let us know about the best application in the medical sector.

For more news on metal 3D printing, subscribe to our 3D printing newsletter. You can also visit us on social media, Facebook and Twitter.

Looking for a job? Visit our 3D Printing Jobs site.

Featured image shows 800 stacked posterior lumbar cages. Image via Betatype.