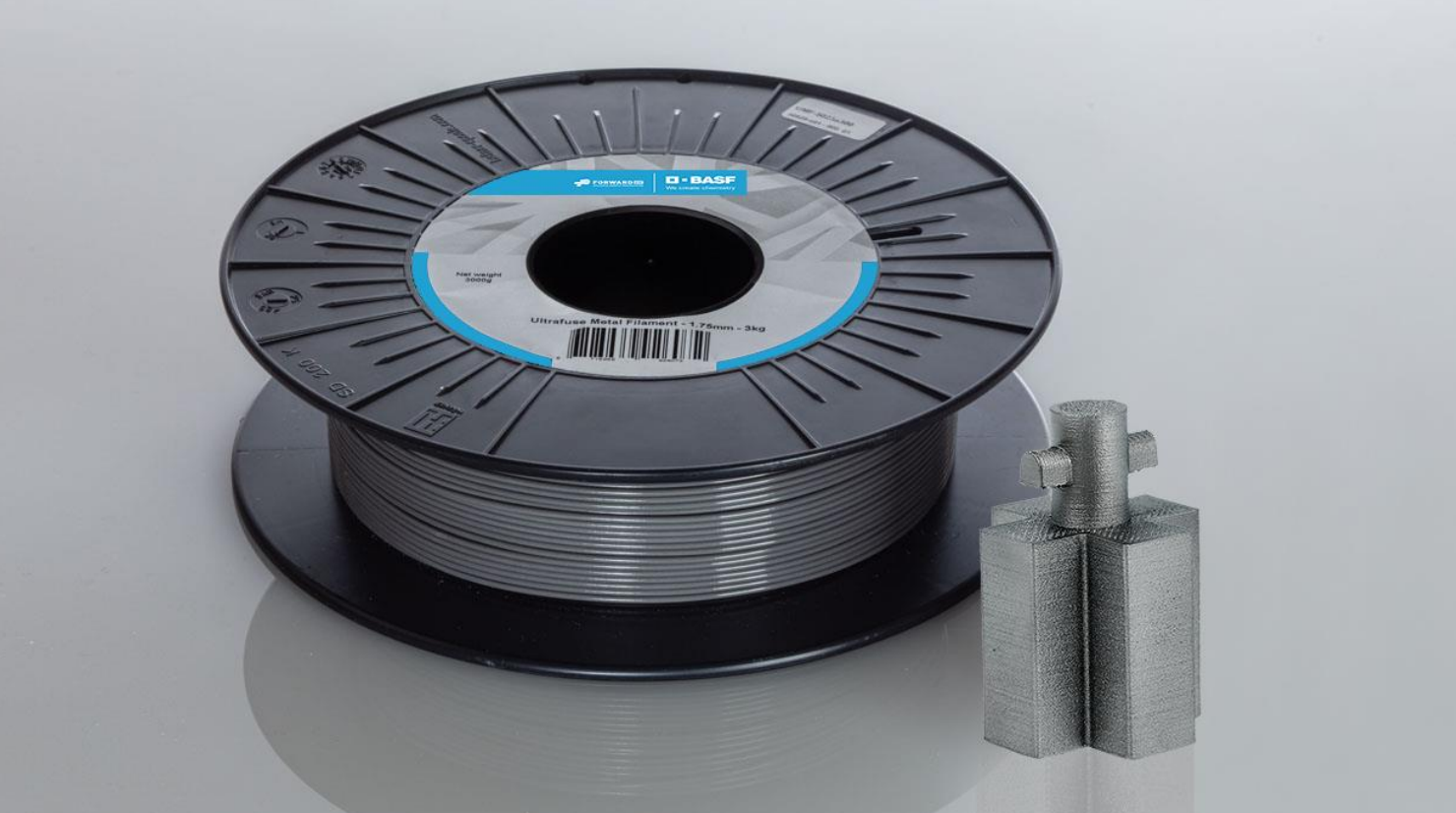

Forward AM, a 3D printing arm of chemical company BASF, has launched its new Ultrafuse 17-4 PH metal filament.

The 17-4 stainless steel-based material comprises metal powder in a polymer matrix, and is designed to enable safe and cost-efficient metal printing on most common FFF systems. Intended for the production of prototypes, metal tooling, and functional components, 17-4 PH brings the high-performance nature of metal to the accessible realm of affordable desktop printing.

Firat Hizal, Head of Metal Systems Group, BASF 3D Printing Solutions, states: “Ultrafuse 17-4 PH is an outstanding result of our strong R&D commitment. We filamented more than 10 different metals from titanium to tool-grade steels, and several alternative materials to print support structures within this year. Going forward we will continue to introduce the new filaments that the market and our customers demand.”

High mechanical strength and hardness

Ultrafuse 17-4 PH is characterized by its excellent mechanical strength and hardness, which it maintains up to a temperature of 315°C. Also known as Type 630, it is a chromium-copper martensitic precipitation hardened stainless steel with magnetic properties. Owing to its notable wear and stress resistance, the material is well suited for tooling, jigs, and fixtures.

The material also features great corrosion resistance, and is fully heat treatable to further improve its strength properties. As such, Forward AM believes its new material will be a “stand-out choice” for components in a whole host of critical industries such as petrochemicals, aerospace, automotive, and even medical.

As is the case with any metal powder-infused filament, parts printed in 17-4 PH will be in their green state straight out of the build chamber. In this fresh untreated state, the material’s properties are sub-optimal, and the part as a whole is extremely fragile. Once the part is heat treated to debind the polymer and sintered to increase its density, what’s left is a fully 17-4 stainless steel 3D printed part with the full set of desirable qualities.

Affordable metal printing with the Ultrafuse range

Last year saw the launch of Forward AM’s first metal filament – Ultrafuse 316L. The Ultrafuse range, now two strong, is specifically designed to be compatible with virtually any common FFF 3D printer, be it consumer or industrial-grade. With the company’s recent heavy investment in material R&D, Ultrafuse technology seems to be shaping up to be one of the more cost-effective methods of metal additive manufacturing.

Hizal concludes: “We have already established a distribution network that collaborates closely with our debinding and sintering service partners in different regions, and can thus deliver an integrated end-to-end solution. We are proud to extend our portfolio with Ultrafuse 17-4 PH.”

Forward AM is not the only company targeting the FFF materials market. 3D printing materials supplier Essentium recently launched three new high-performance composite filaments specially designed for applications in aerospace, defense, electronics and more. The first, TPU 58D-AS, has anti-static properties, whereas PET-CF and 9085 are characterized by their excellent heat and chemical resistances.

Elsewhere, 3D printing filament supplier Reflow recently launched a new eco-friendly range of ‘Seaglass’ translucent materials. The company’s new line of six rPETG filaments is made from locally-sourced sustainable plastic, and is visually inspired by the environment.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows parts 3D printed with Ultrafuse 17-4 PH. Photo via BASF.