Generative design is a method of automating design by setting parameters that a software has to follow. The set of rules or parameters sometimes follow a random set of numbers, or an evolutionary algorithm, but the parameters can really be anything. Most commonly employed in parametric modeling, generative design is most often inspired by the natural design processes and patterns of nature. In this way, genetic variations, mutations, and crossovers are incorporated into the design output. It can be used in the areas of design, architecture, and product design to ask “what would nature do?” How would nature support or grow support structures here, or optimize a load bearing topology?

Last week, Autodesk announced the availability of a software suite of generative design solutions called Autodesk Within. The product is based on the technology of Within Labs, a London startup acquired by Autodesk in 2014. According to a recent blog post, Autodesk Within is a tool “to help engineers create and 3D print lightweight designs for the automotive, aerospace, industrial equipment and medical implant industries.”

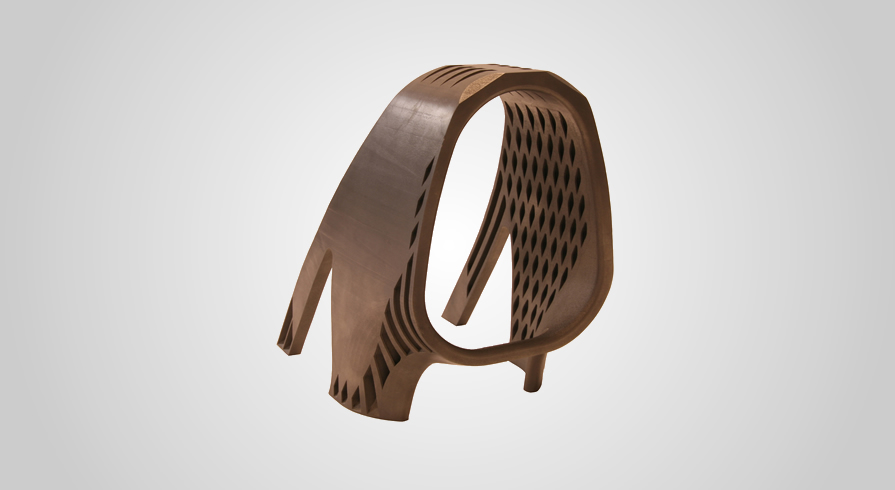

So, how does it work? The software centers around an optimization engine. A user will set input parameters (i.e. weight requirements, displacement, maximum stress), then Autodesk Within generates phenomenal looking designs with variable-density lattice structures and surface skins that meet the input criteria. The performance and weight of the resulting design will increase and decrease, respectively. The interesting idea behind Autodesk Within is how empowering it is for the user to be able to optimize for weight and performance, while deciding how stiff or flexible an object, product, or component should turn out.