The Sinterit Lisa SLS 3D printer is now supported by Autodesk Netfabb, the industrial additive manufacturing and design software tool.

The collaboration between Sinterit, who were established by ex-Google employees, and Autodesk aims to reduce costs and facilitate additive manufacturing.

User-friendly, professional SLS 3D printers

Sinterit tell us their mission is to manufacture as user-friendly as possible professional SLS printers. According to the company, “By integrating the Sinterit Lisa printer with Autodesk Netfabb industrial additive software, the users of this popular design solution can start using their new printer almost immediately without needing to learn how to use another piece of software.”

The Lisa 3D printer can be operated using Netfabb in the Standard, Premium or Ultimate levels. This allows the working environment settings to be adjusted immediately in Netfabb to the needs of a specific 3D printer, considering, for example, how much material it uses or how it produces models.

To make SLS printing even easier, Sinterit has just added a sieve developed for Lisa that increases the speed of removing powder and facilitates multiple uses of the material. Additionally, printer users have recently received other new features: automatic levelling of the powder surface, automatic setting of the bed heights, and the possibility to multiply prints in the working space. Equipped with all existing and new features, Sinterit Lisa provides an easy end-to-end solution for SLS printing.

SLS 3D printing for under €15,000

The production of very detailed and solid models without the need to print any supports is a significant advantage of selective laser sintering. Additionally, many objects can be printed simultaneously. Until recently, the only SLS printers available on the market cost around €100,000. Sinterit Lisa costs less than €15,000 and fits on a desktop. With the combination of compact size and user-friendliness, Sinterit has made SLS printing available to these companies that have been using FMD technology so far or which have outsourced the preparation of 3D prints.

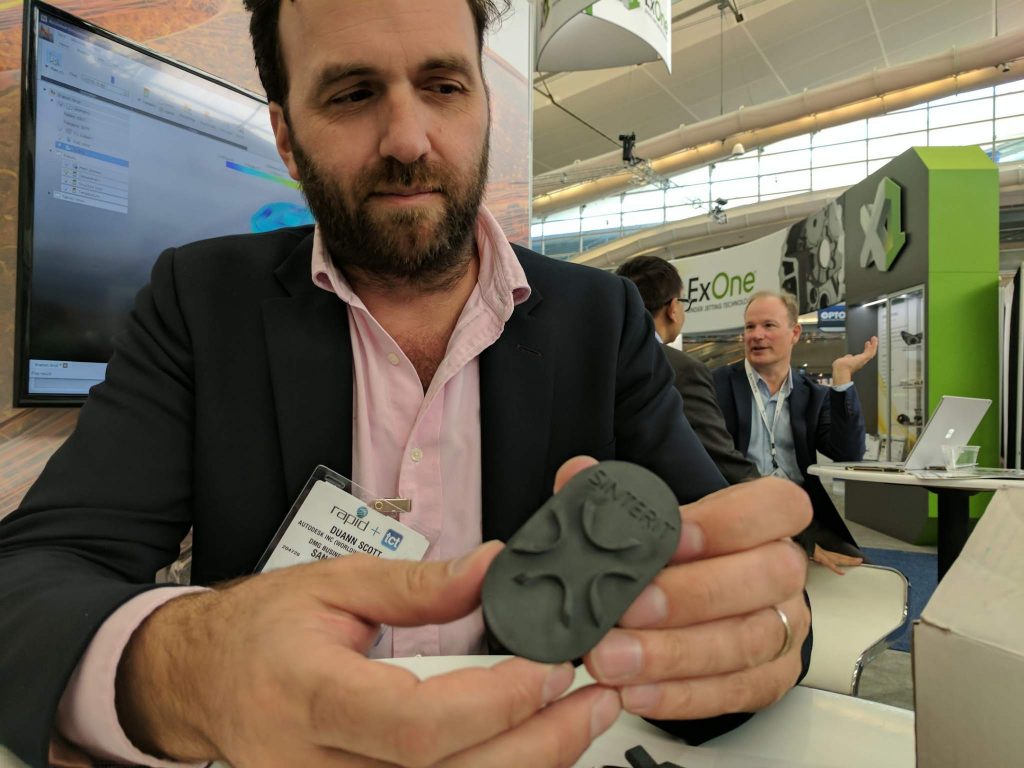

“The SLS process provides design freedom and material options that enable high quality, end-use parts not possible with other additive, or traditional manufacturing techniques and Sinterit is democratizing access to this technology with a massive reduction in price without compromising on part quality,” said Duann Scott, Additive Manufacturing and Composites Strategist at Autodesk.

Autodesk Netfabb gives Sinterit users access to industrial grade optimization for the SLS process, at the part, build packing and parameter level to ensure professional results from the desktop SLS 3D Printer. This combination of affordable, professional software and hardware will open up the use cases for polymer additive manufacturing.

More information about Sinterit is available here.

To stay up to date with the latest 3D printing developments in aerospace and other related news sign up to the 3D Printing Industry newsletter, like us on Facebook and follow us on Twitter.