3D printing software developer Authentise has partnered with the Manufacturing Intelligence division of Hexagon AB, a Sweden-based global technology company, to develop an end-to-end software offering designed to make 3D printing more predictable, repeatable, and traceable.

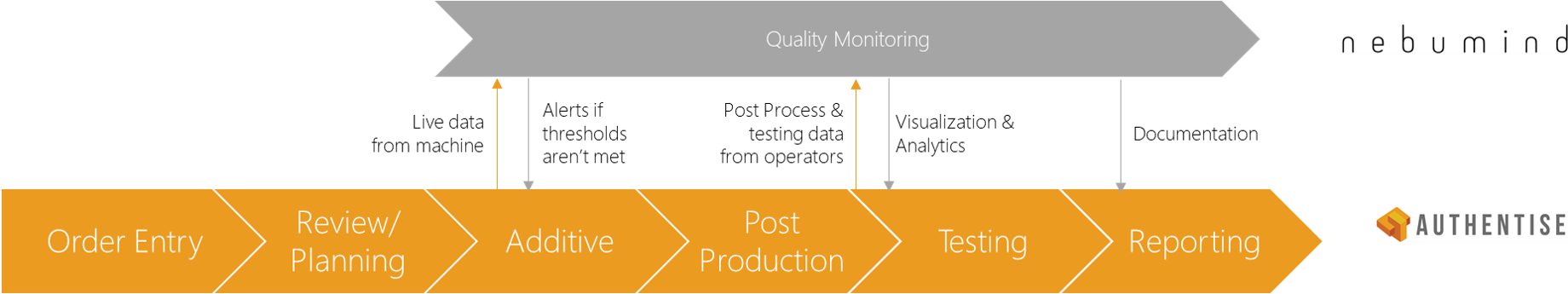

The partners are working to digitize every step of the additive manufacturing workflow through expanding the control loop from the machine level to include data from design, manufacturing operations, and quality assurance in an end-to-end value chain. Ultimately, the software is engineered to automate serial production improvements and enable improved 3D printing designs.

“Together with Authentise, we are building a next-generation framework for our customers to manage flexible, fully digitized production workflows in private cloud environments,” said Mathieu Pérennou, Global Business Development Director Additive Manufacturing within Hexagon’s Manufacturing Intelligence Division. “For manufacturers, AM is a complex and changing market with many excellent tools, printers and materials to apply. We believe our open and flexible systems will enable us to respond quickly to customer’s needs and integrate with their unique environments

“This will connect that data flow and help streamline their workflows in all stages of the AM process – before, during and after production and support their specific standards of compliance needs.”

End-to-end software for 3D printing

The technical challenge of connecting data from all areas of the additive manufacturing value chain, such as manufacturing operations from the factory floor, engineering data from the design phase, material properties and quality data from validation inspection processes, has so far held back advancements in automated serial production and design improvements of 3D printed parts.

Hexagon and Authentise are seeking to overcome these technical challenges and accelerate the industrialization of 3D printing through their partnership by digitizing each step of the workflow, from part design through to production and quality assurance.

The firms have undertaken a shared commitment to open architectures that integrate data and automate workflows between Hexagon’s applications for 3D printing and third-party equipment and software chosen by manufacturers. Hexagon and Authentise will utilize their respective technology capabilities to connect the digital thread of parts and increase their traceability.

Throughout the partnership, the companies will make use of methods such as statistical process control (SPC), machine learning (ML), and artificial intelligence (AI) in order to eliminate waste and quality issues during the design phase of a print, while also improving the repeatability of 3D printing processes within a single site or between global locations.

“We are excited to combine Hexagon’s solutions with our open workflow management engine to offer a unique end-to-end solution platform,” said Andre Wegner, CEO of Authentise. “Integrating data from Hexagon’s best-of-breed software and sensors helps deliver a seamless experience for users, automation across their process, and unlocks the ability to learn from data.”

Authentise and Hexagon

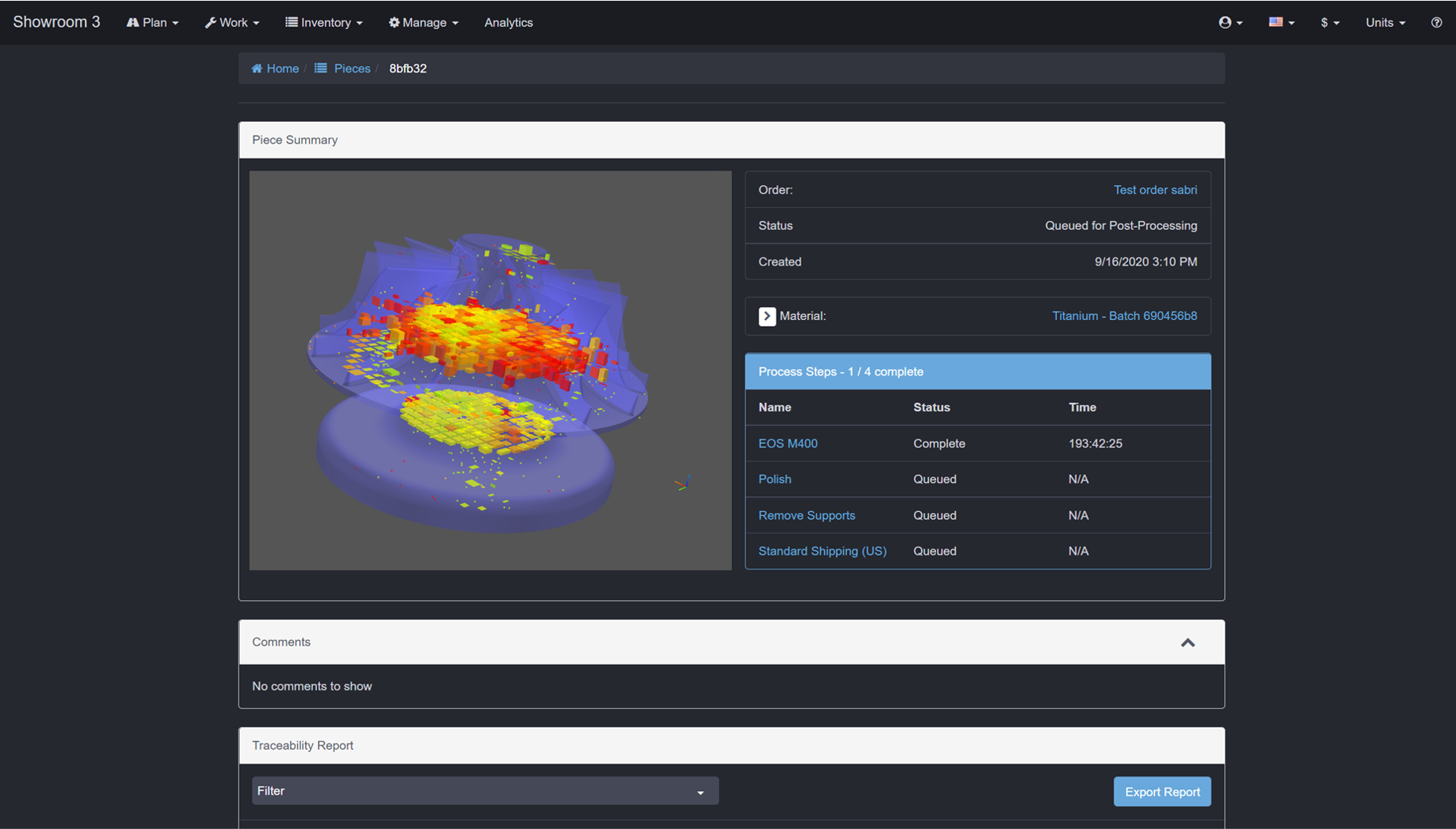

Founded in 2012, Authentise develops data-driven process automation software for 3D printing. The company’s core product is its Authentise Manufacturing Execution System (AMES), an additive workflow management engine which gathers data from 3D printers to seamlessly generate order status updates, automated actions, and system optimization reports.

The firm has previously collaborated the likes of multinational technology corporation Microsoft to integrate its AMES platform into the cloud-based Microsoft Flow software, and real-time process monitoring systems developer Addiguru to incorporate AI-based in-situ monitoring functionality into the system.

Since then, it has added several new updates to AMES, including a material traceability feature and integrated digital twin visualizations from data vizualization and analytics provider nebumind to more easily identify problem zones of parts.

As a result of its latest partnership, Authetise is a key partner in Hexagon’s growing open additive manufacturing ecosystem. Through the ecosystem, Hexagon can build tailored 3D printing applications to the specific needs of its customers, spanning a variety of industries and complexities from volume production of precision metal gears to bespoke aerospace parts from composites.

“This partnership represents a step change for the industry – together we’re delivering the integrated digital thread for additive manufacturing that customers have sought for so long,” added Wegner.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows direct 3D printer control from Authentise’s platform. Image via Authentise.