Researchers from the Graz University of Technology, Austria, the University of Vienna, and the FAU University of Erlangen-Nuremberg (FAU) have 3D printed neodymium (NdFeB) supermagnets to be used in clean energy devices.

NdFeB is an earth metal element used with iron and boron to create strong permanent magnets. Laser powder bed fusion (LPBF) was applied to fabricate NdFeB microstructural magnets that would not be feasible using conventional manufacturing. Such components could potentially be used for magnetic switching systems and sensors within wind turbines and electric motors.

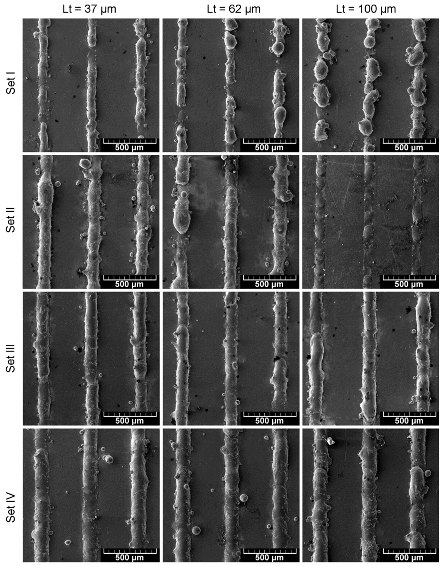

“With the technique of additive manufacturing it is possible to produce parts with more complex design; however, obtaining printing processes for functional materials is still a topic in research and development,” the research published in Materials states.“In LPBF, [NdFeB] powder was completely melted, which resulted in the formation of a new microstructure responsible for the coercive field strength.”

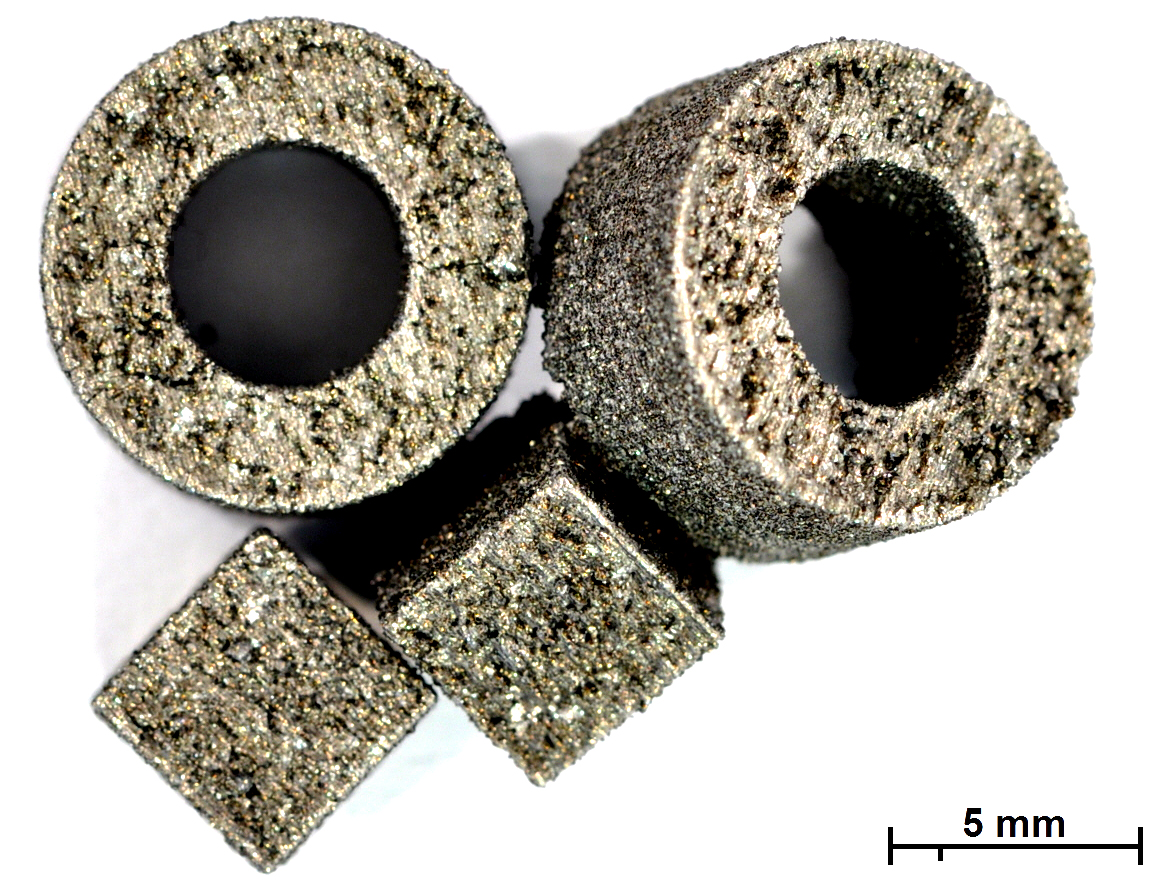

3D printed supermagnets

According to researchers, NdFeB magnets are used within integral computers and smartphone components but have yet to be implemented in other applications including electric brakes, magnetic switches, and certain electric motor systems. The 3D printed supermagnets were designed as an alternative to common NdFeB magnets which are resource-intensive, and not particularly sustainable.

A process was then developed to 3D print magnets purely of metal with a high relative density while maintaining control of its microstructures. Siegfried Arneitz and Mateusz Skalon from the Institute of Materials Science, Joining and Forming at TU Graz, stated, “The combination of both these features enable efficient material use because it means we can precisely tailor the magnetic properties according to the application.”

Improving rare metals

As stated by Arneitz, rare earth metals lose their magnetic properties at higher temperatures, while special Fe-Co alloys maintain their magnetic performance at temperatures of 200° to 400°C and show good temperature stability. Upon evaluation of melt-pool stability, it was found the 3D printed NdFeB materials displayed increased magnetic performance.

“Theoretical calculations have shown that the magnetic properties of these materials can be improved by a factor of two or three,” added Arneitz. “We’re going to continue working on this topic so we can develop alternative magnetic materials for areas in which neodymium magnets are not necessary.”

Graz University of Technology has previously conducted research to modified 316L stainless steel powder for additive manufacturing for better print quality and surface finish. A group of this institute is also working on a project investigating the development of 3D printed concrete parts for construction.

“Influence of Melt-Pool Stability in 3D Printing of NdFeB Magnets on Density and Magnetic Properties” is co-authored by Mateusz Skalon, Michael Görtler, Benjamin Meier, Siegfried Arneitz, Nikolaus Urban, Stefan Mitsche Christian Huber, Joerg Franke, and Christof Sommitsch.

Think this is award-winning research? Nominations for the 2020 3D Printing Industry Awards are now open.

Keep up to date with industry-relevant financial reports this season by subscribing to the 3D Printing Industry newsletter, following us on Twitter and liking us on Facebook.

Seeking jobs in engineering? Make your profile on 3D Printing Jobs, or advertise to find experts in your area.

Featured image shows 3D printed miniaturized super magnets. Photo TU Graz.