Researchers from the University of Technology Sydney (UTS), together with biotech firm Regeneus, have created what they claim is the world’s first 3D printed microfluidic device capable of harvesting stem cells.

Bleeding-edge stem cell therapies are a promising way to treat a whole plethora of ailments, including arthritis, diabetes, and potentially even cancer. Stem cells work by differentiating into specialized cells, meaning they can be used to replace damaged cells around the human body. Unfortunately, harvesting and processing stem cells from donors is currently very time, cost, and labor intensive due to limitations in biotechnology.

The 3D printed microfluidic device is designed to harvest stem cells from bioreactors, offering a scalable method of processing stem cells without the associated costs.

Professor Majid Warkiani, the UTS biomedical engineer leading the research, said, “Our cutting-edge technology, which uses 3D printing and microfluidics to integrate a number of production steps into one device can help make stem cell therapies more widely available to patients at a lower cost.”

Microfluidics and 3D printing

The field of microfluidics is concerned with the precise control of very small volumes of fluids at microscopic scales, which is great for manipulating cells and particles for biomedical applications.

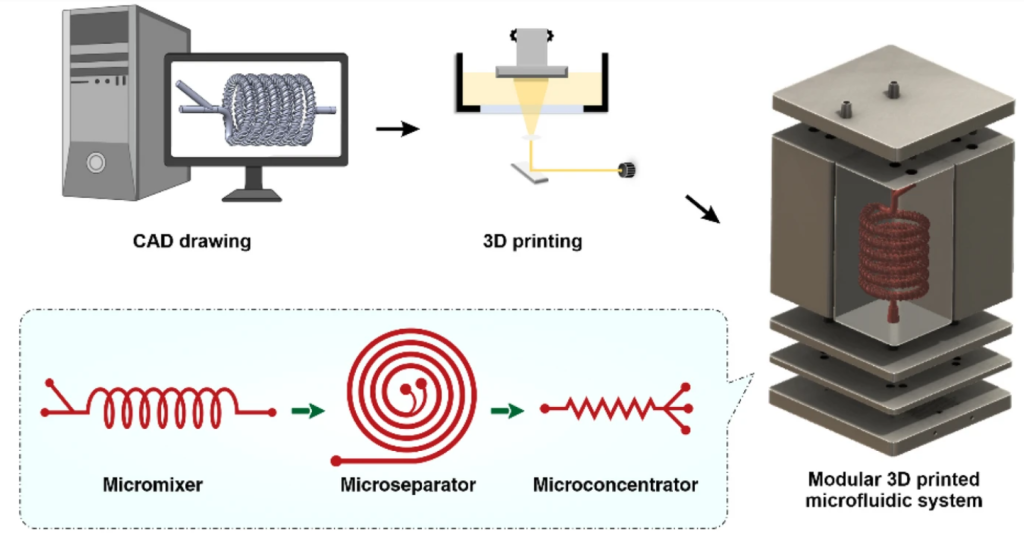

Until now, microfluidics devices haven’t really been able to find their footing in the industrial space due to high costs of testing and errors in precision. However, with micro-3D printing now an option, researchers are able to directly manufacture microfluidics apparatus with the hopes of transitioning from the lab to fully-fledged industrial systems.

“While this world-first system is currently at the prototype stage, we are working closely with biotechnology companies to commercialize the technology. Importantly, it is a closed system with no human intervention, which is necessary for current good manufacturing practices,” adds Warkiani.

The 3D printed stem cell harvester

UTS’ one-of-a-kind harvester is designed to process mesenchymal stem cells, a kind of adult stem cell that can differentiate into bone, cartilage, muscle, and fat cells. Before processing, mesenchymal stem cells are extracted from donor bone marrow, fat, or blood, and transferred to laboratory bioreactors where they’re combined with microcarriers that allow the cells to grow.

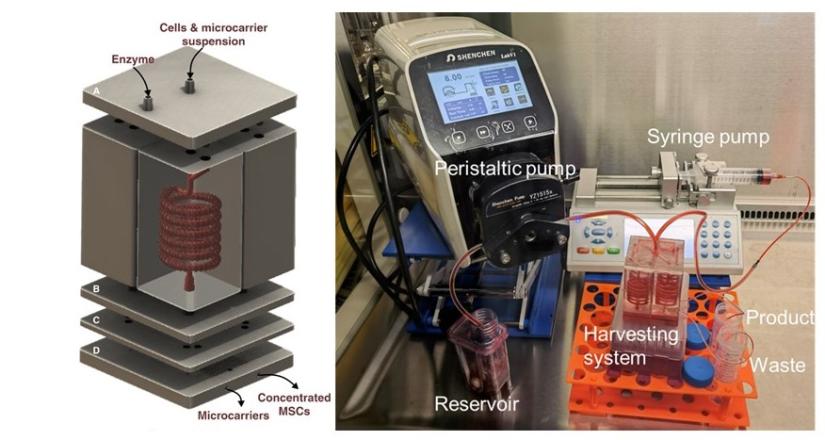

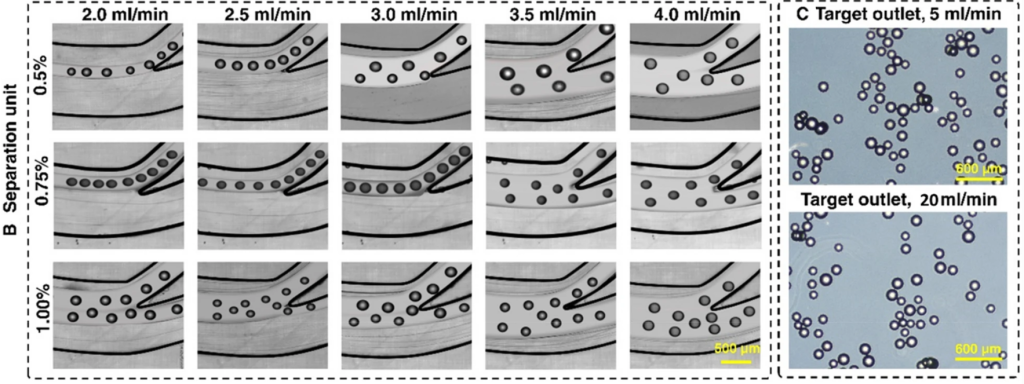

The 3D printed harvester comprises four micromixers, one spiral microfluidic separator, and one microfluidic concentrator that work to separate mesenchymal stem cells from their microcarriers without compromising cell viability and functionality. This allows them to be concentrated for further processing before being used in a clinical setting.

The system has already been shown to be scalable for large industrial-grade cell volumes. Warkiani also says that the technology can address other industrial challenges in the bioprocessing space, ultimately reducing the cost of stem cell therapeutics while vastly increasing stem cell and CAR-T cell quality.

Further details of the study can be found in the paper titled ‘A modular 3D printed microfluidic system: a potential solution for continuous cell harvesting in large-scale bioprocessing’.

This certainly isn’t the first time microfluidic technology has featured in the additive manufacturing sector. Earlier this year, Phase Inc, a North Carolina-based medical 3D printing startup, partnered with Virginia Tech to advance the field of microfluidics 3D printing. Together, Phase and Virginia Tech will use the former’s proprietary LE3D printing technology to develop novel microfluidic devices that will help researchers formulate new and improved medical treatments for conditions such as brain cancer.

More recently, researchers from the Stevens Institute of Technology used computational modeling techniques to advance microfluidics-based 3D bioprinting, and they hope it can one day enable the fabrication of entire human organs.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the harvester separating stem cells from their microcarriers. Image via UTS.